Air curtain sprayer and spraying gun applying same

A technology of air curtain and nozzle, which is applied in the field of spraying guns, can solve problems such as paint waste, and achieve the effect of reducing scattering and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

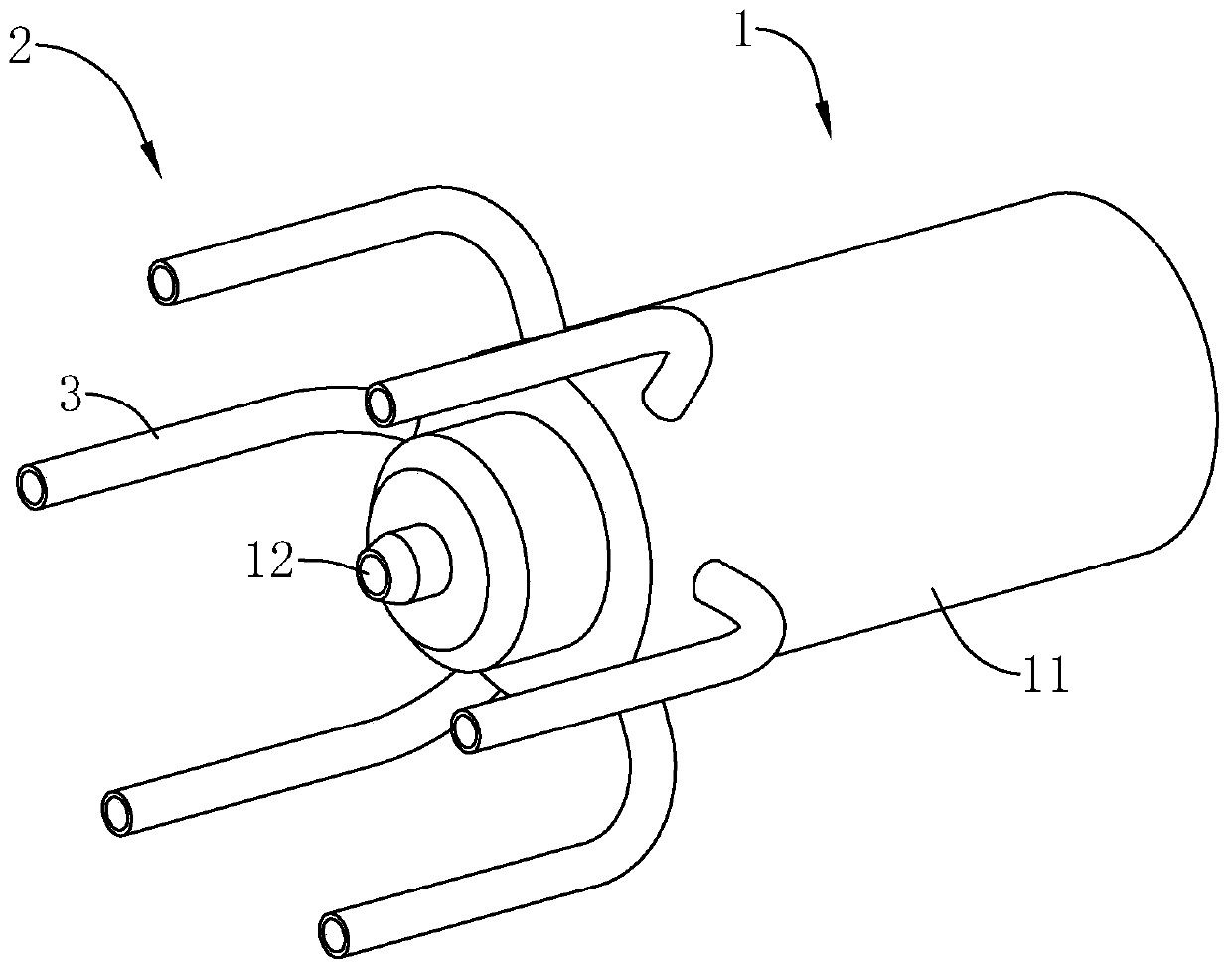

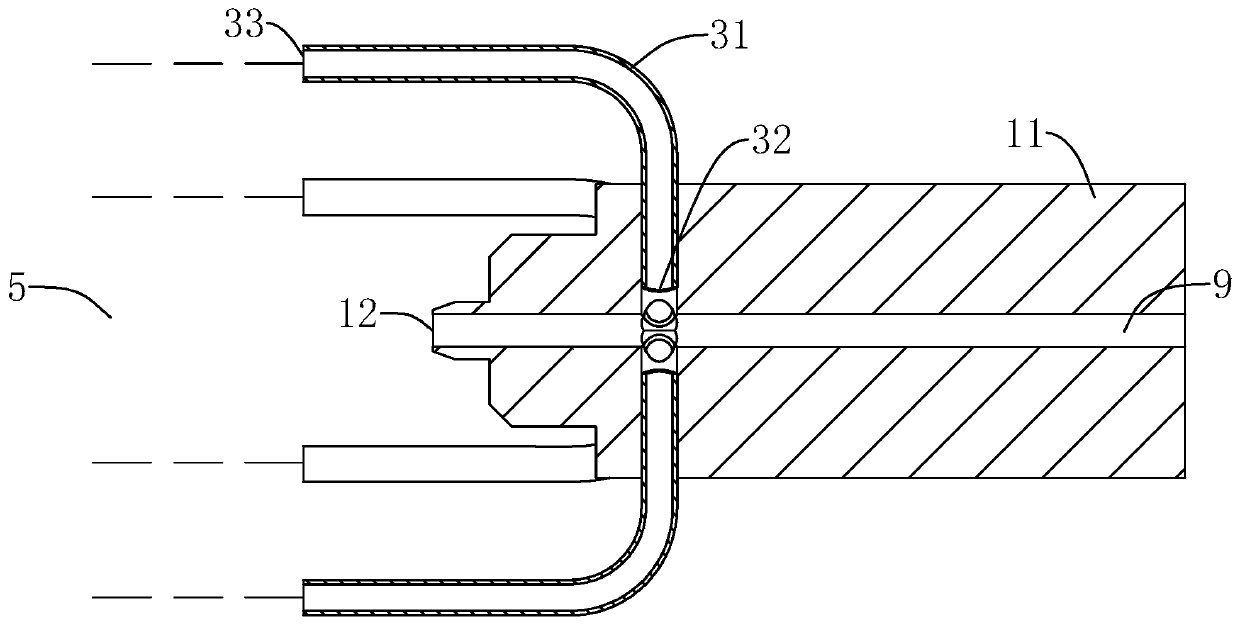

[0042] refer to figure 1 , figure 2 , is an air curtain spray head disclosed by the present invention, including a main spray head 1 for spraying paint, an air flow piece 2 surrounding the main spray head 1 is arranged on the outer wall of the main spray head 1, and the air flow piece 2 is used to spray air flow to form a restriction The main spray head 1 sprays the air curtain space 5 of the paint range.

[0043] The airflow part 2 includes several airflow nozzles 3 fixedly connected to the outer wall of the main nozzle 1. In this embodiment, the number of the airflow nozzles 3 is preferably six, and the six airflow nozzles 3 are evenly arranged along the circumferential direction of the main nozzle 1. ; The air jet direction of each air nozzle 3 is the same as the direction in which the main spray nozzle 1 sprays paint.

[0044] The main nozzle 1 comprises a nozzle 11 and a nozzle opening 12 arranged at one end of the nozzle 11, and the nozzle 11 is provided with an air p...

Embodiment 2

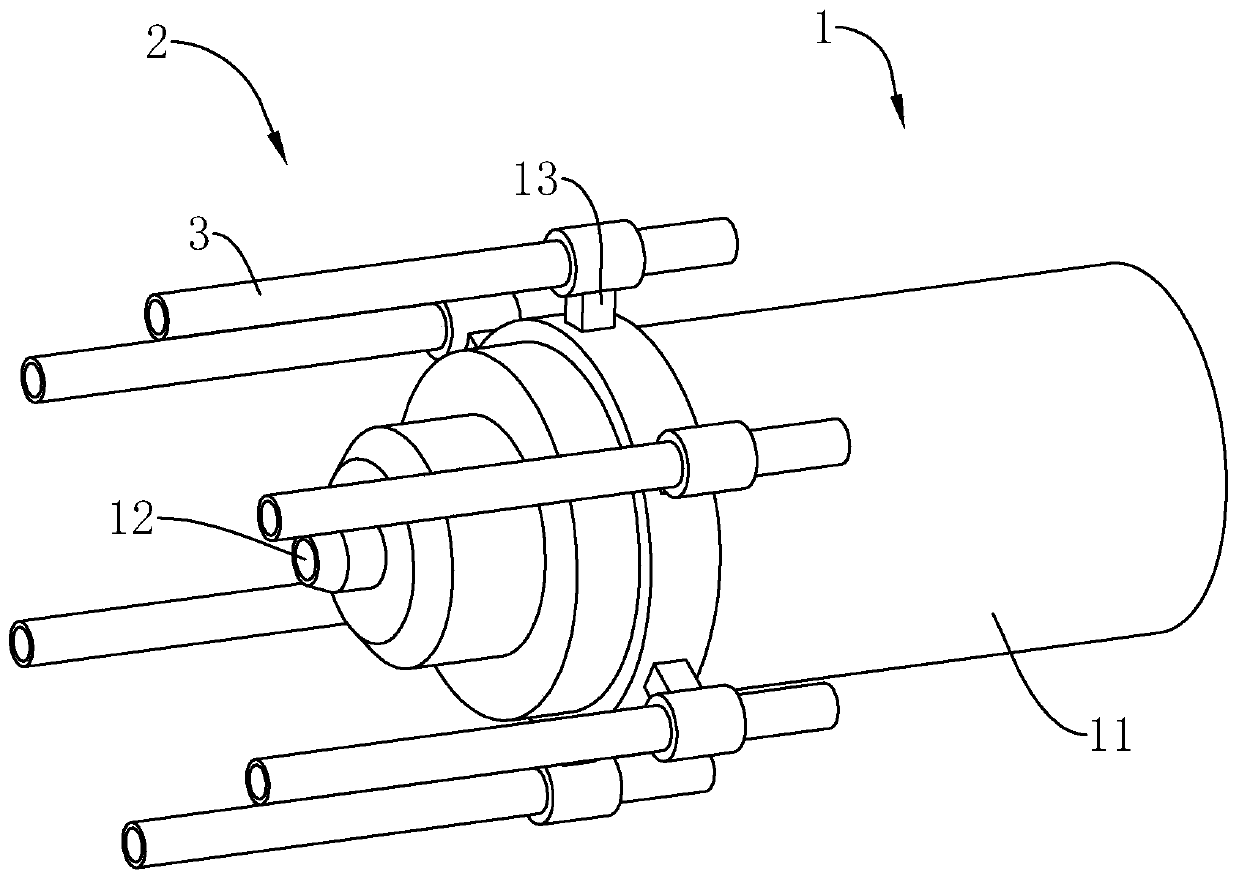

[0048] refer to image 3 , Figure 4 , based on a further improvement of Embodiment 1, an air curtain spray head, including a main spray head 1 for spraying paint, the outer wall of the main spray head 1 is provided with an air flow piece 2 surrounding the main spray head 1, and the air flow piece 2 includes several along the main spray head. The airflow nozzles 3 uniformly arranged in the circumferential direction of the nozzle 1, the airflow injection direction of each airflow nozzle 3 is the same as the direction in which the main nozzle 1 sprays paint.

[0049] On the outer wall of the main nozzle 1, the position corresponding to each air flow nozzle 3 is fixedly connected with a connecting rod 13, and the end of the connecting rod 13 away from the main nozzle 1 is fixedly connected to the outer wall of the corresponding air flow nozzle 3, and the air flow nozzle 3 Including the pipe body 31, the two ends of the pipe body 31 are provided with an air inlet 32 and an air ...

Embodiment 3

[0051] refer to Figure 5 , Image 6 , based on a further improvement of Embodiment 1, an air curtain spray head, including a main spray head 1 for spraying paint, an air flow member 2 surrounding the main spray head 1 is arranged on the outer wall of the main spray head 1, and the air flow member 2 is used for spraying air And form the air curtain space 5 that limits the scope of spraying paint by the main spray head 1.

[0052] The main nozzle 1 includes a nozzle 11 and a nozzle opening 12 disposed at one end of the nozzle 11 , and a connecting air passage 42 communicated with the nozzle opening 12 is opened in the nozzle 11 along the axial direction.

[0053] The airflow part 2 includes an airflow ring 4 sleeved on the outer wall of the main nozzle 1. The airflow injection direction of the airflow ring 4 is the same as the direction in which the main nozzle 1 sprays paint, and the end surface of the airflow ring 4 is provided with a ring along the circumferential direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com