Integrated printing device and printing method of continuous fiber embedded material

A continuous fiber and embedded material technology, applied in the direction of manufacturing auxiliary devices, additive processing, manufacturing tools, etc., can solve the problems of unsuitable high-melting point polymer printing, uneven distribution of continuous fibers, and inability to bond polymers, etc., to achieve Good adhesion, low environmental protection, good automatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

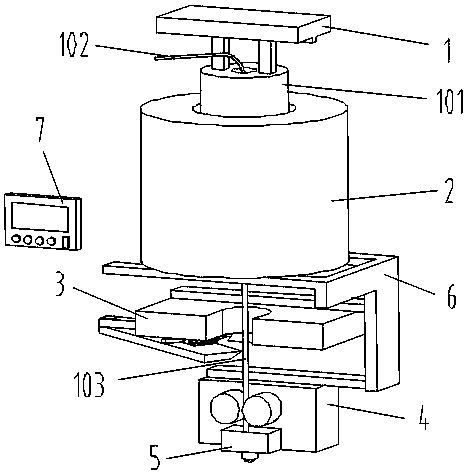

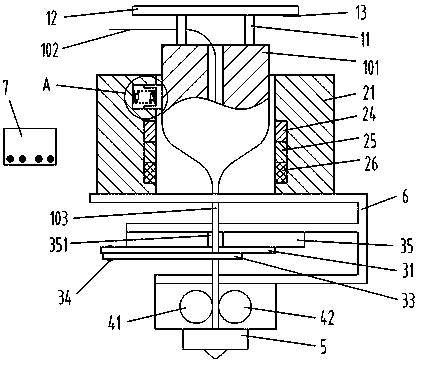

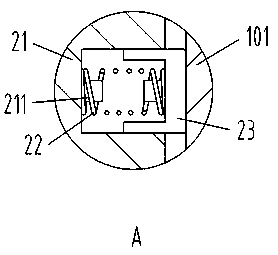

[0036] see Figure 1 to Figure 5 As shown, the integrated printing device and printing method of the continuous fiber embedded material of the present invention, a polymer cylinder with holes is prefabricated into a filament rod, and the continuous fiber is passed through the hole of the filament rod, and the filament rod is formed by a compact Clamped in the center of the filament forming tube, the push rod located at the upper end of the filament forming mechanism continuously pushes the filament forming rod downward. The filament forming rod passes through the heating zone, and the molten polymer flows down and wraps on the surface of the continuous fiber, and finally flows from the bottom of the filament forming tube The forming wire comes out, and the forming wire passes through the measuring and shearing mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com