Device and method for rapidly testing effective thermal conductivity of porous metal material on basis of guarded hot plate method

A porous metal, rapid measurement technology, applied in the direction of material thermal development, etc., can solve the problem of increasing experimental measurement investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

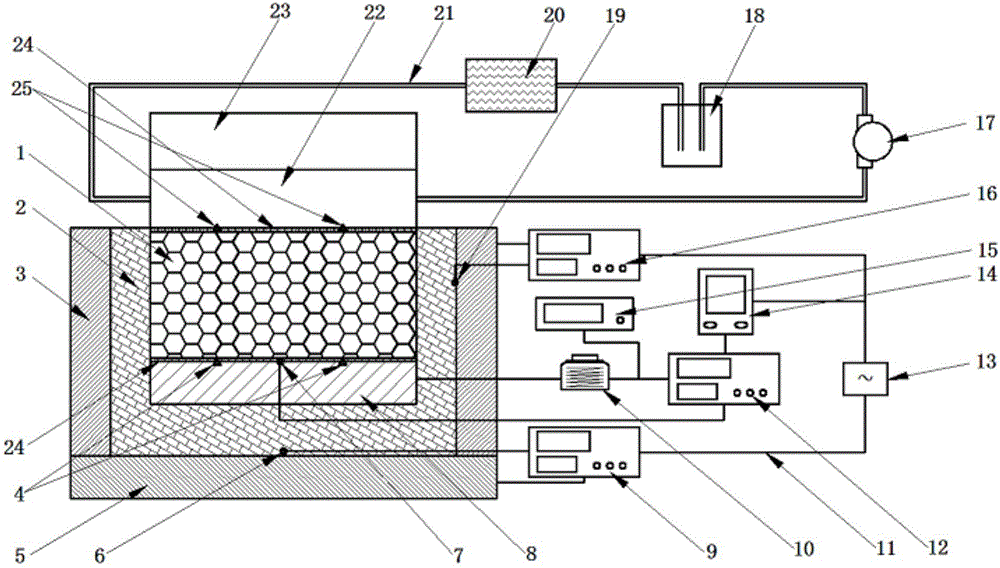

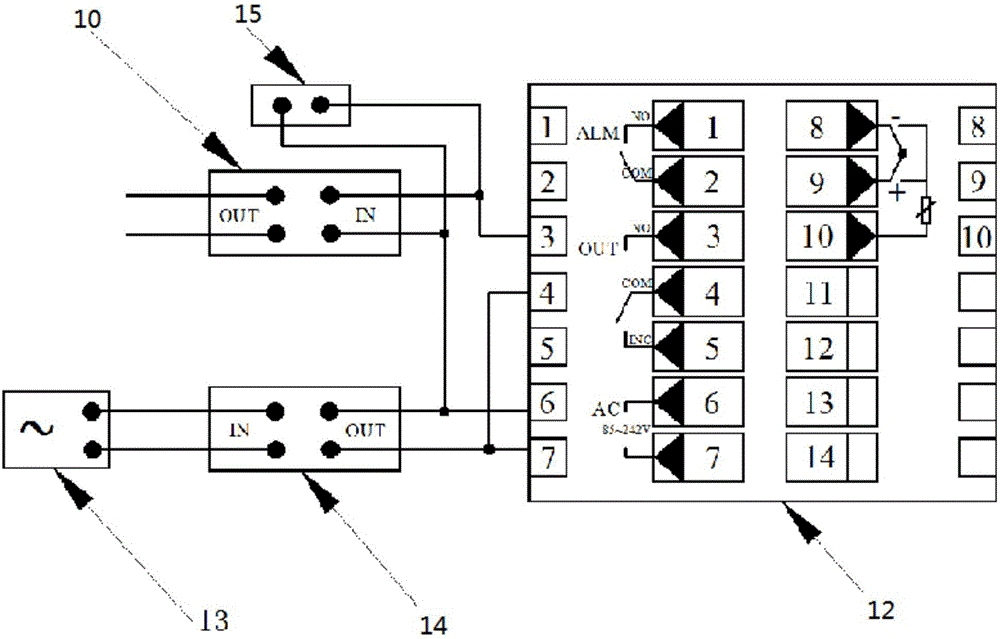

Embodiment Construction

[0047] The present invention will be described in further detail below.

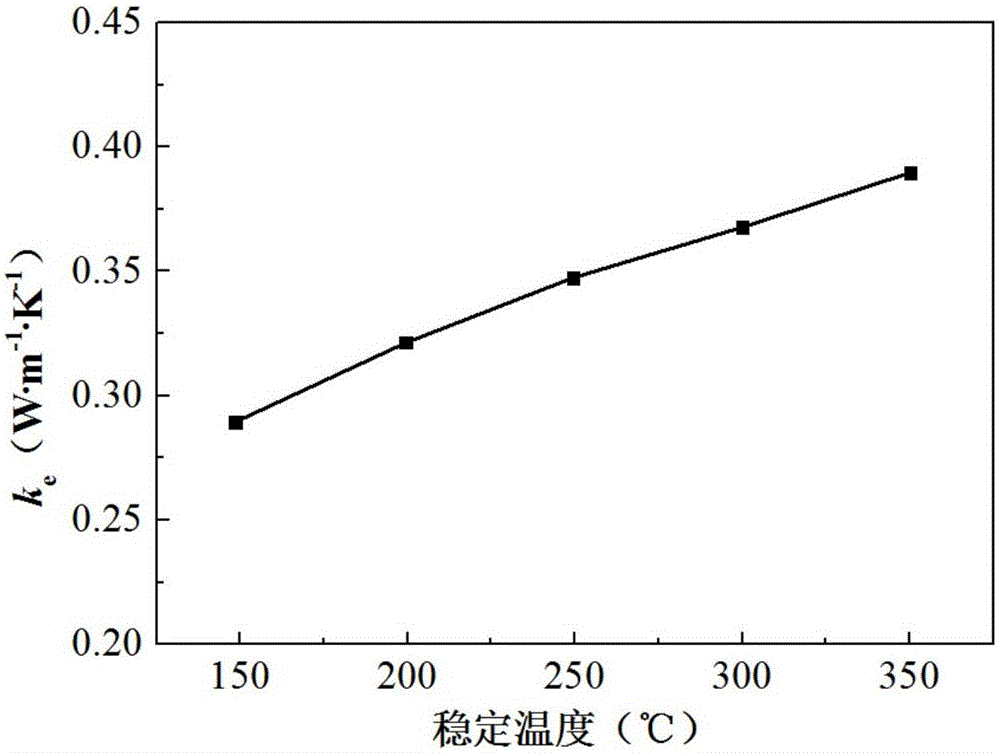

[0048] 1. Test principle:

[0049] According to Fourier's law, in the case of one-dimensional steady-state heat transfer, the effective thermal conductivity k of the object e It can be expressed by the following formula:

[0050] k e = q Δ T / H = Q · H Δ T · A

[0051] Among them: where q is the heat flux density, ΔT is the temperature difference between the cold end and the hot end when the object is measured, H is the thickness of the measured sample, A is the nominal cross-sectional area of the measured sample, and Q is the heat transfer per unit time.

[0052] In view of the working mode of the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com