Glass fiber reinforced plastic seat back mounting structure for rail vehicle

A rail vehicle and installation structure technology, which is applied in the field of rail vehicles, can solve the problems of inconvenient installation of seats, and achieve the effect of easy packaging and convenient installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

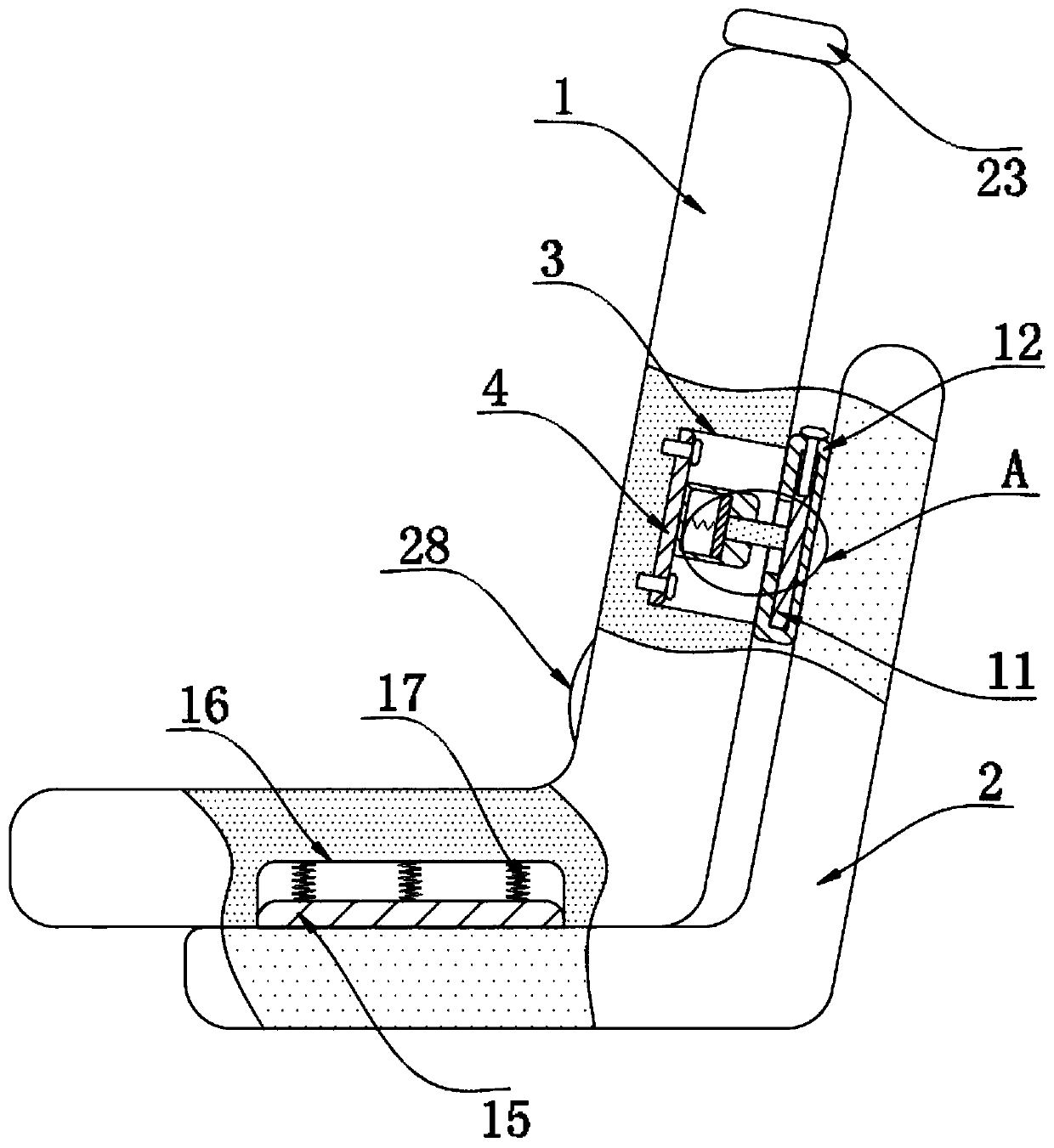

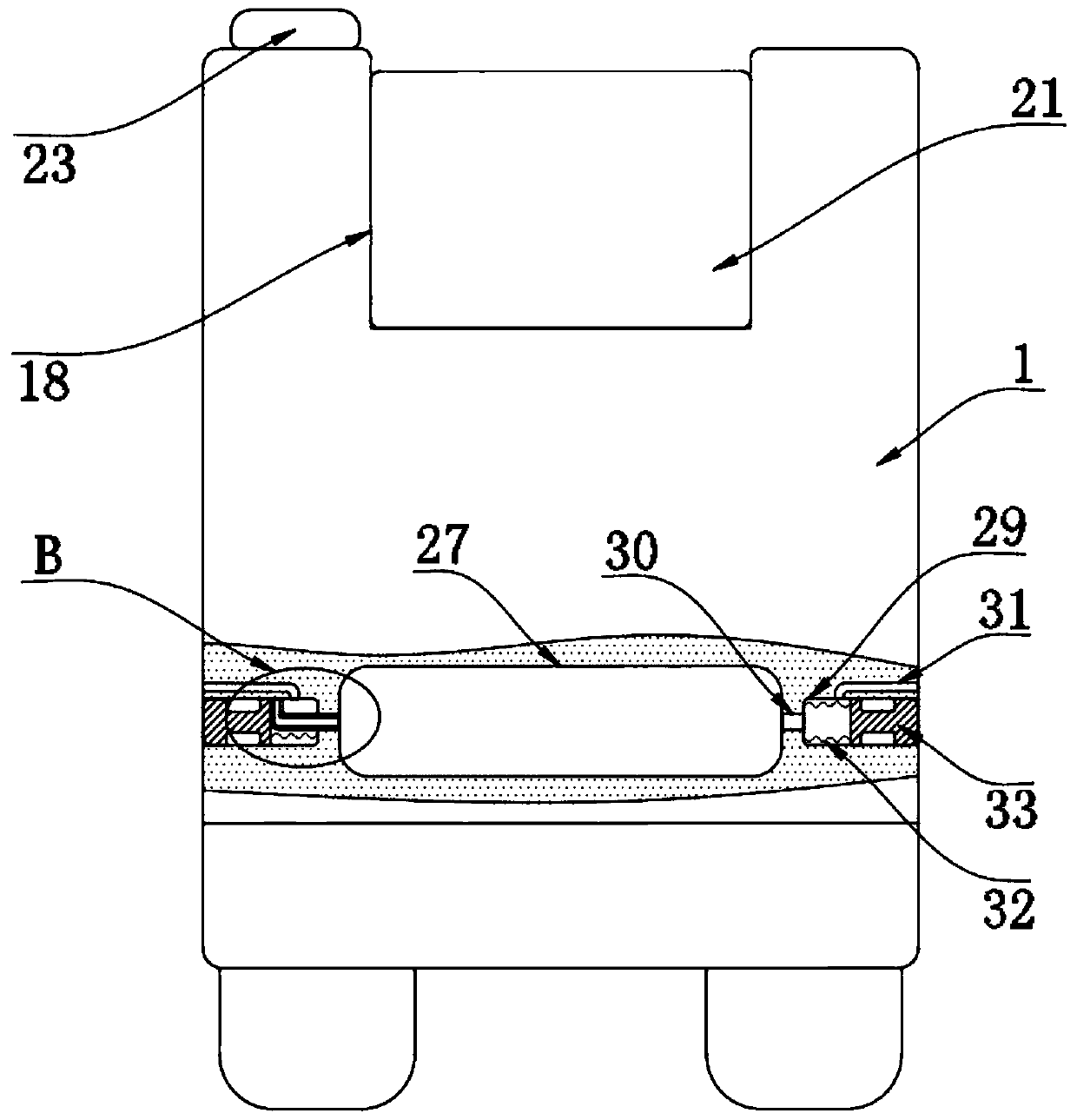

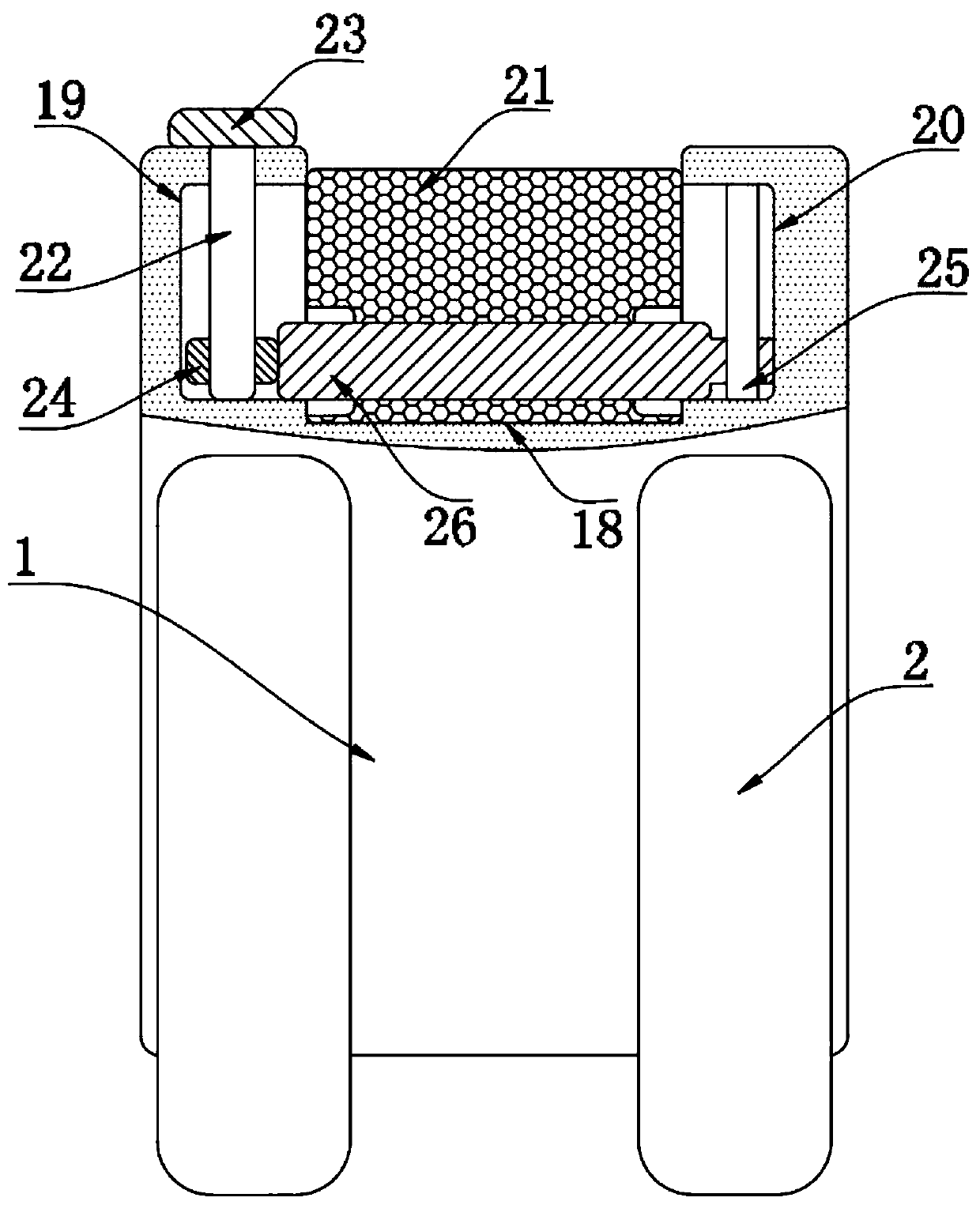

[0027] refer to Figure 1-5 , a fiberglass seat back installation structure for rail vehicles, comprising a seat body 1 made of fiberglass material and two mounting brackets 2 for installing the seat body 1, the side walls of the two mounting brackets 2 are welded Mounting block 12, the side walls of two mounting blocks 12 all run through and are provided with mounting groove 13, and two mounting grooves 13 are all provided with reversing groove 14 near seat body 1 side, and the side wall of seat body 1 is provided with The two mounting blocks 12 are correspondingly connected to the clamping device, the side walls of the two mounting brackets 2 are welded with a limit block 15, and the bottom of the seat body 1 is provided with two symmetrically arranged limit grooves 16, and the two limit grooves The inner bottom of 16 is all welded with one group of buffer springs 17, and two stoppers 15 are respectively connected with the sliding connection of two stopper grooves 16 inwalls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com