A kind of phosphomolybdic acid intercalation hydrotalcite-like lightweight foam heat insulation material and preparation method thereof

A technology of lightweight foam and thermal insulation material, applied in the field of biomass foam materials, can solve the problems of poor fire resistance, high thermal conductivity, unenvironmental protection, etc., and achieve the effects of low thermal conductivity, high flame retardant effect, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

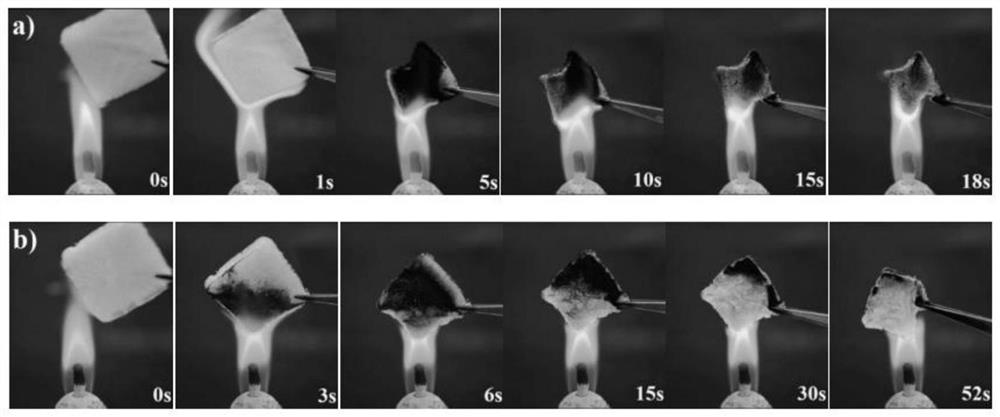

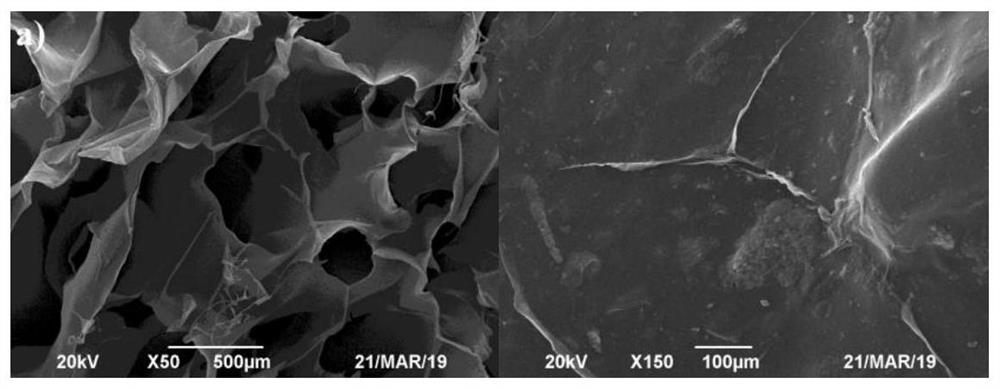

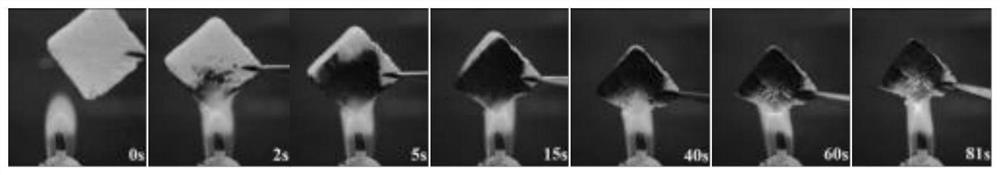

[0038] M of a specific embodiment of the present invention 2+ 1-x m 3+ x -PMo 12 o 40 -LDHs / cellulose lightweight foam thermal insulation material and preparation method thereof, comprising the following steps:

[0039] (1) Prepare M by co-precipitation method 2+ 1-x m 3+ x - LDHs precursors.

[0040] (2) The LDHs precursor in (1) was modified by ion exchange method to obtain M 2+ 1-x m 3+ x -PMo 12 o 40 -LDHs. The guest can be phosphomolybdic acid or various phosphomolybdates.

[0041] (3) The M obtained in (2) 2+ 1-x m 3+ x -PMo 12 o 40 - LDHs, cellulose, linking agent, etc. are stirred evenly according to a certain mass ratio, and the lightweight foam refractory material is prepared by freeze-drying method.

[0042] As preferably, in the step (1), the co-precipitation method is: weighing the hydrated M 2+ Salt, M 3+ The salt is formulated into a mixed salt solution in proportion, and in N 2 Under the atmosphere, stir vigorously with the alkali solu...

Embodiment

[0062] 1. Press n(Zn 2+ ) / n(Al 3+ )=3:1 Weigh Zn(NO 3 ) 2 .9H 2 O and Al(NO 3 ) 3 .9H 2 O, adjust the pH value to 7.0, react at 70°C for 12h, and prepare ZnAl-NO by co-precipitation method 3 -LDHs.

[0063] 2. press m 主体 / m [PMo12O40] 3- =1:2 Accurately weigh a certain mass H 3 PMo 12 o 40 Dissolved in deionized water, neutralized with quantitative NaOH to obtain sodium phosphomolybdate solution. in N 2 Under the atmosphere, the sodium phosphomolybdate solution was added dropwise to the ZnAl-NO 3 - Stir vigorously in the LDHs main body slurry; make the reaction solution react at a set temperature of 60° C. for 14 hours. After repeated washing with deionized water, dry under normal pressure at 50°C for 24 hours to obtain ZnAl-PMo 12 o 40 -LDHs white solid.

[0064] 3. According to the dry weight mass percentage ratio (CNF+PMo-LDHs+H 3 BO 3 Total 100%), the ZnAl-PMo 12 o 40 - LDHs slurry and CNF are mixed and stirred evenly; and a certain amount of boric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com