A light-weight and wear-resistant multifunctional composite power single rope and its manufacturing method

A technology of compound power and production method, applied in the direction of sports accessories, equipment for mountaineering, braided fabrics, etc., can solve the problems of inconvenientness and achieve the effect of good energy absorption and buffering capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

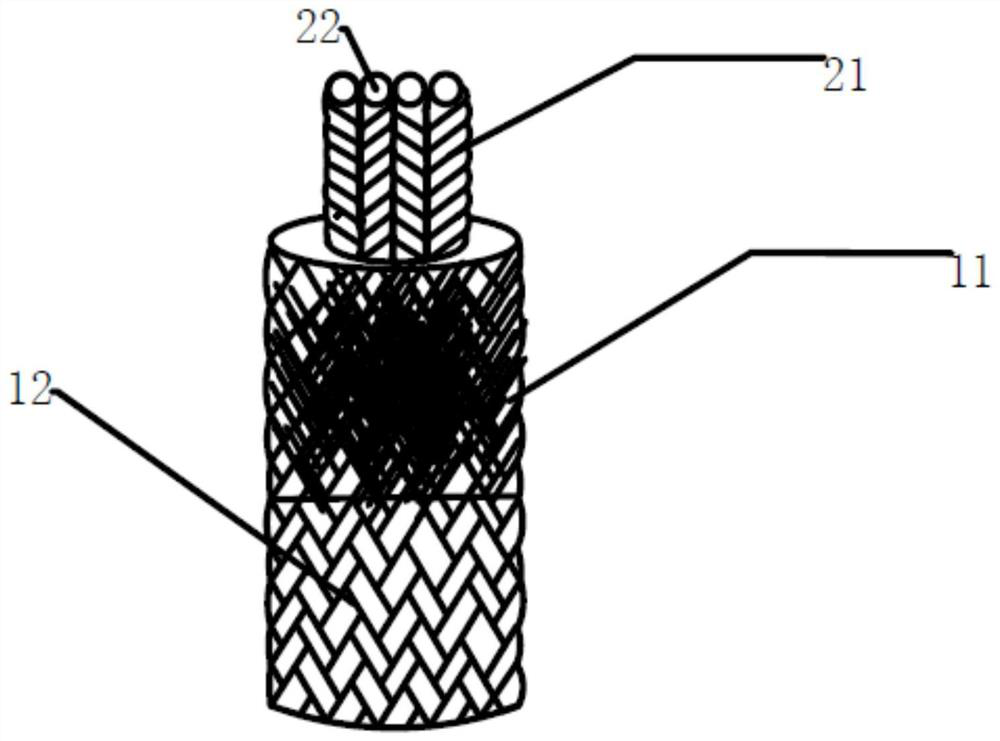

[0076] The lightweight wear-resistant multifunctional composite power single rope disclosed in Example 1 is made by the following method:

[0077] (1) The composite rope core is made of polyamide fiber and high-strength low-elongation fiber, including:

[0078] (1-1) Select 8 polyamide fibers with a specification of 840D, and first twist to obtain the first rope core first twist strand, and the initial twist twist is set to 200 twists / meter; Retwisting, obtaining the first rope core retwisting strand, the retwisting direction is opposite to the initial twisting direction, and the retwisting twist is set to 160 twists / meter;

[0079] (1-2) Select 8 high-strength and low-elongation fibers with a specification of 840D, and first twist to obtain the first-twisted strands of the second rope core; the initial twist twist is set to 200 twists / meter; The strands are retwisted to obtain the second rope core retwisted strands, the retwisting direction is opposite to the initial twistin...

Embodiment 2

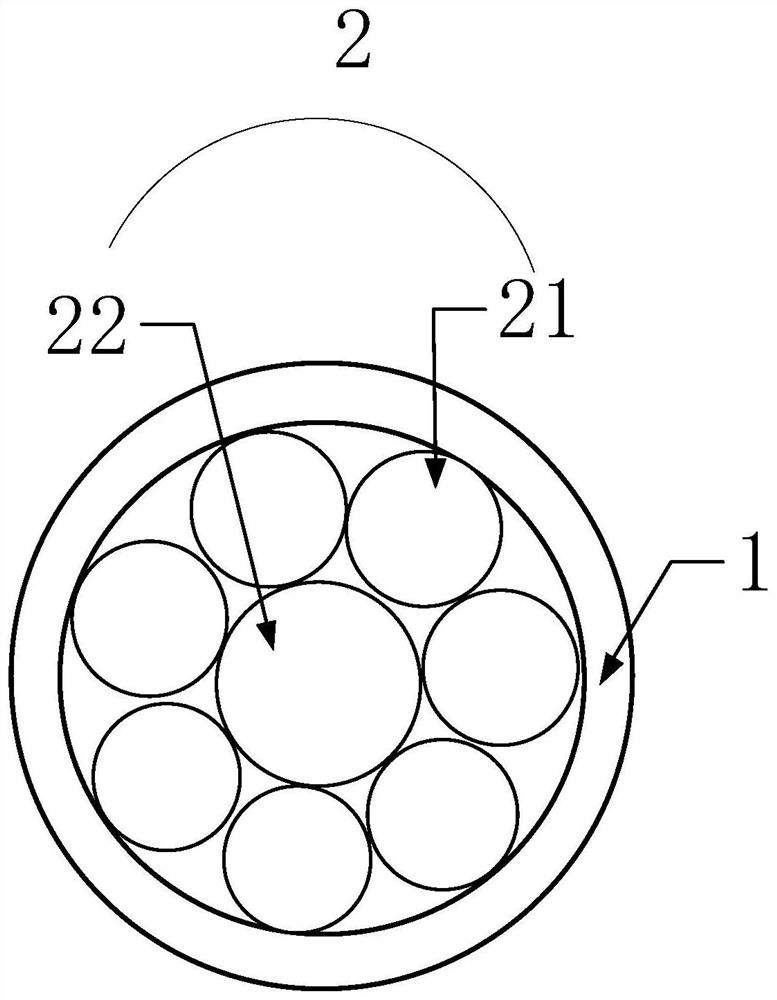

[0088] The lightweight wear-resistant multifunctional composite power single rope disclosed in Example 2 is made by the following method:

[0089] (1) The composite rope core is made of polyamide fiber and high-strength low-elongation fiber, including:

[0090] (1-1) Take 8 polyamide fibers whose specification is 1260D, and the initial twist is the first rope core strand, and the initial twist twist is set to 150 twists / meter;

[0091] (1-2) Take 8 high-strength and low-elongation fibers with a specification of 1260D, and the initial twist is the second core rope strand, and the initial twist twist is set to 150 twists / meter;

[0092] (1-3) pre-weaving the first core rope strand and the second core rope strand respectively on the pre-loom to obtain strands corresponding to the capacity of the bobbins;

[0093] (1-4) Putting the pre-woven bobbin on a braiding machine for braiding to obtain a braided composite rope core.

[0094] (2) The composite rope core is heat-set, the he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com