A construction method for shock-absorbing protection system of hard rock subway station in medium-hole method blasting excavation

A technology for subway stations and protection systems, which is applied to earth drilling, mining equipment, tunnels, etc., can solve the problems of poor concrete appearance and serious damage, and achieve the effects of avoiding concrete respraying, reducing damage, and ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

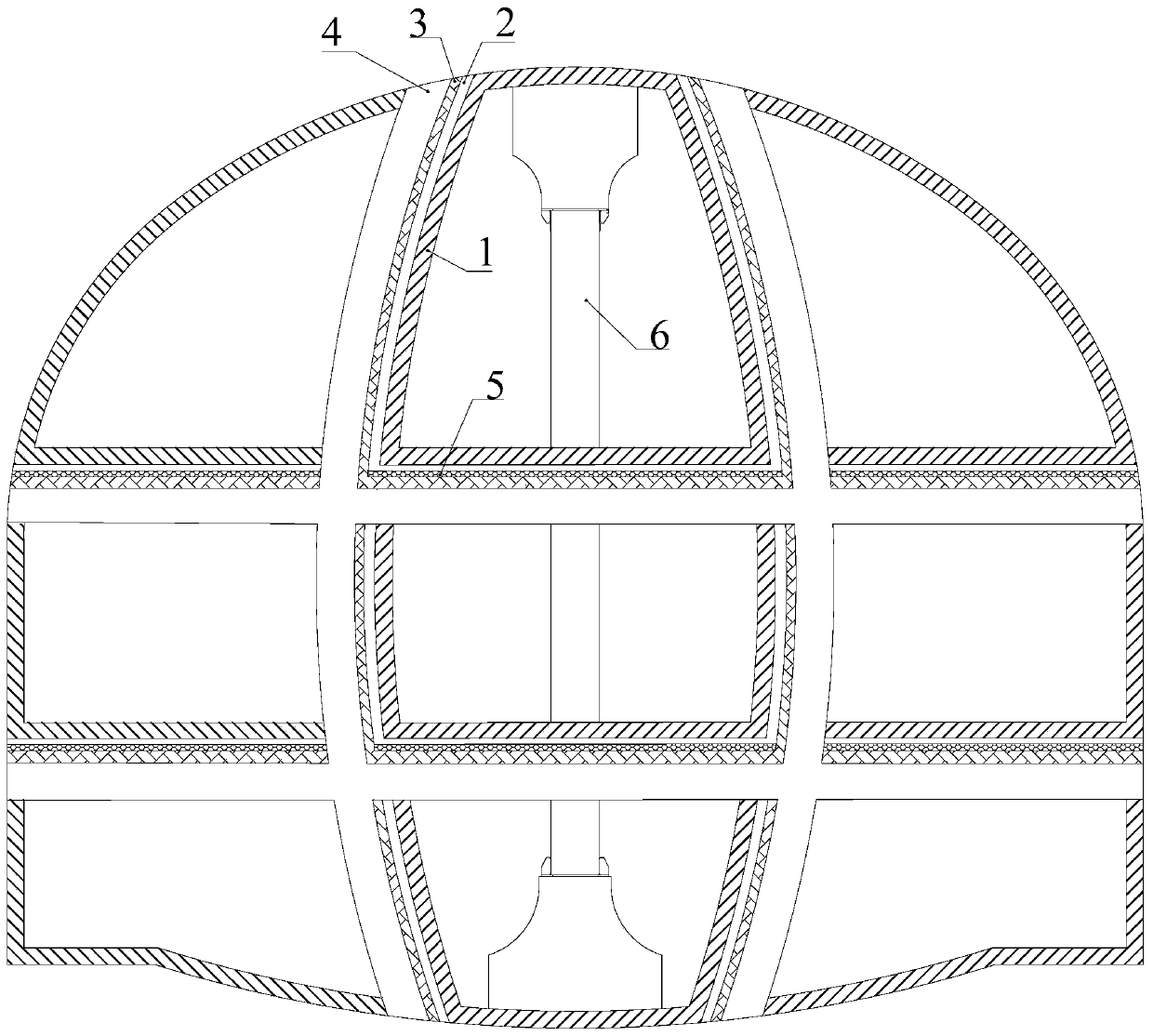

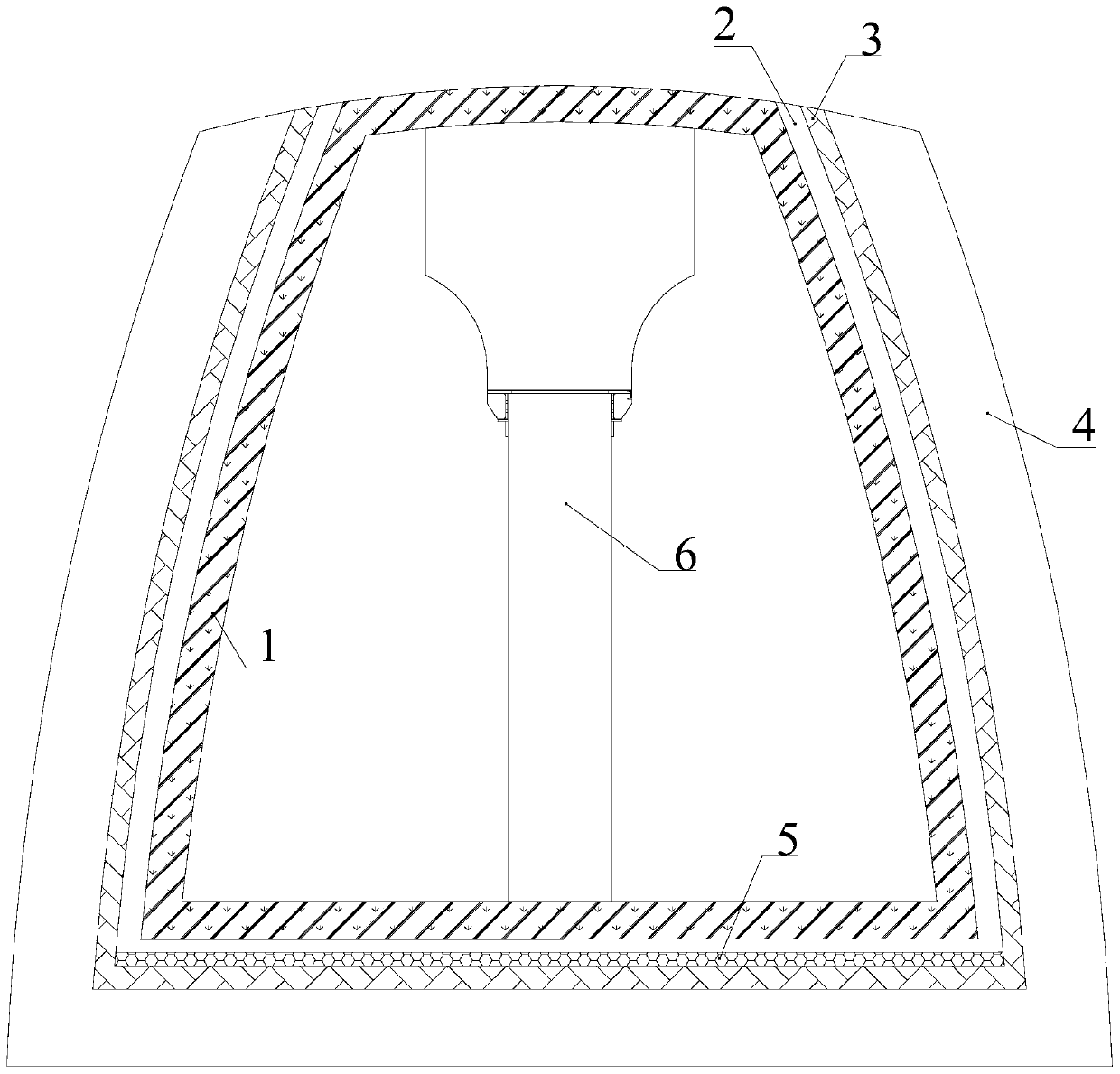

[0032] Such as Figure 1-2 As shown, the middle column 6 in the construction of the middle hole method is the component that mainly bears the upper load. The upper load is transmitted to the middle column 6 through the arches on both sides of the middle column 6 and the top longitudinal beam, and finally the middle column 6 transmits the force to the foundation. . Due to the large number of pilot tunnels in the construction of the middle tunnel method, it is necessary to set up more temporary supports 1 to control the deformation of the rock and soil mass.

[0033] In order to reduce the damage to the temporary support 1 by blasting as much as possible, the present invention provides a shock-absorbing protection system for hard rock subway stations in the middle-hole method blasting excavation, including benzene plates laid on the side walls and inverted arches respectively 3. A concrete layer 2 is arranged on the benzene slab 3, and a blasting buffer rock wall 4 with a thick...

Embodiment 2

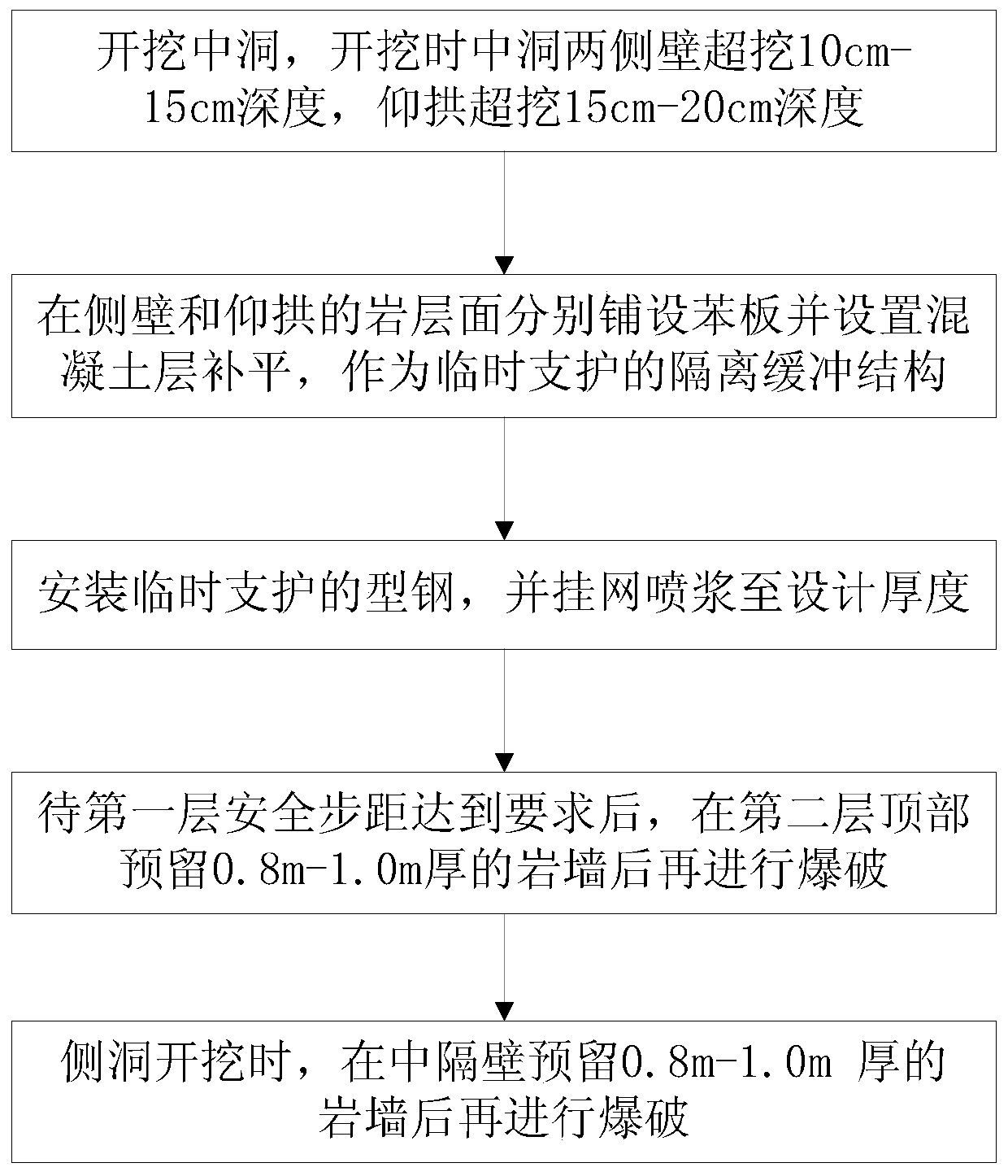

[0036] Such as image 3 As shown, the present invention also provides a construction method of a shock-absorbing protection system for a hard rock subway station in the middle-hole blasting excavation, including the above-mentioned shock-absorbing protection system for a hard rock subway station in the middle-hole blasting excavation , its construction method is:

[0037] Step 1: Excavate the middle hole. During the excavation, the two side walls of the middle hole are over-excavated to a depth of 10cm-15cm, and the depth of the inverted arch is over-excavated to a depth of 15cm-20cm;

[0038] Step 2: Lay benzene board 3 on the rock surface of the side wall and make up with sprayed concrete layer 2, first lay a crushed stone isolation layer 5 on the rock surface of the inverted arch, and then spray concrete layer 2 on the crushed stone isolation layer 5 to make up flat, as an isolation buffer structure for temporary support 1;

[0039] Step 3: Install the profiled steel of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com