car bumper

A technology for bumpers and automobiles, applied in bumpers, vehicle parts, traction connectors, etc., can solve the problems of fragile collision, poor forming performance, and high cost of bumper materials, and achieve the effect of reducing damage and reducing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to solve the above problems, the present invention provides an automobile bumper.

[0033] To achieve the above object, the present invention adopts the following technical solutions:

[0034] A car bumper, comprising:

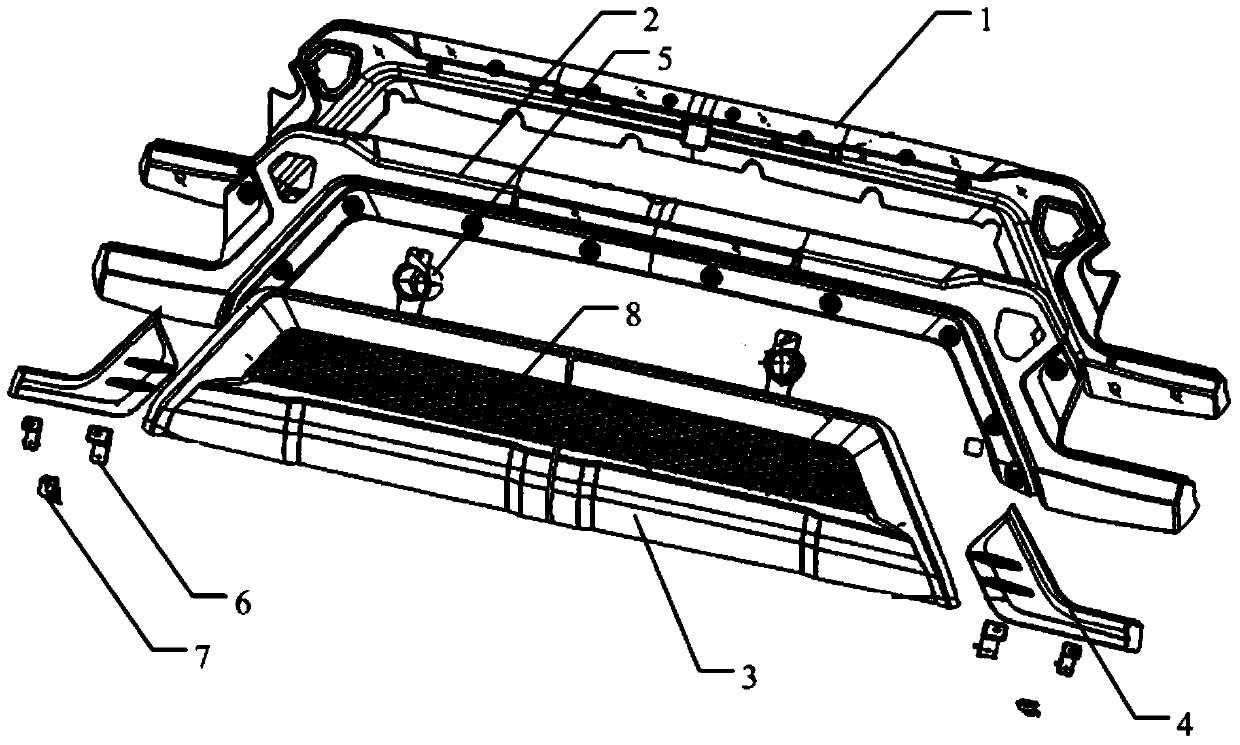

[0035] Main bar body 1, shell 2, guard plate 3, decoration 4, tow hook 5, connecting piece 6 and carbon steel pull code 7;

[0036] The surface of the main bar body 1 is designed with several grooves and round holes. The grooves can increase the physical bonding force between the shell 2 and the main bar body 1. During foam molding, the polyurethane forms an I-shaped connection through the round holes of the main body 1, so that The shell 2 is closely connected with the main bar body 1 .

[0037] It should be noted that the shell 2 is polyurethane foamed with a density of 0.45-0.5g / cm3, which is integrally covered on the outer surface of the main bar body 1 through a foaming process, with a thickness of 5-7mm, and the appearance surface is et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com