Prefabricated column with space steel truss platform and capable of realizing pitch point cast-in-situ connection

A technology for steel trusses and prefabricated columns, applied in the field of prefabricated columns, can solve the problems of increasing construction difficulty, failing to detect the anchoring quality of steel bars and grouting materials in sleeves, increasing the construction period of nodes, etc., and reducing the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] When a frame structure building with a storey height of 3 meters adopts the prefabricated column of the present invention which can realize the node cast-in-place connection and the self-contained space steel truss platform, the structure of the prefabricated column can be:

[0041] The strength grade of the concrete used to make the column 2 is C35, the steel bar grade is HRB400, the diameter of the longitudinally stressed steel bar is 25mm, the diameter of the inner column stirrup and the node stirrup is 8mm, and the cross-sectional size of the beam passing through the node is 200mm×500mm.

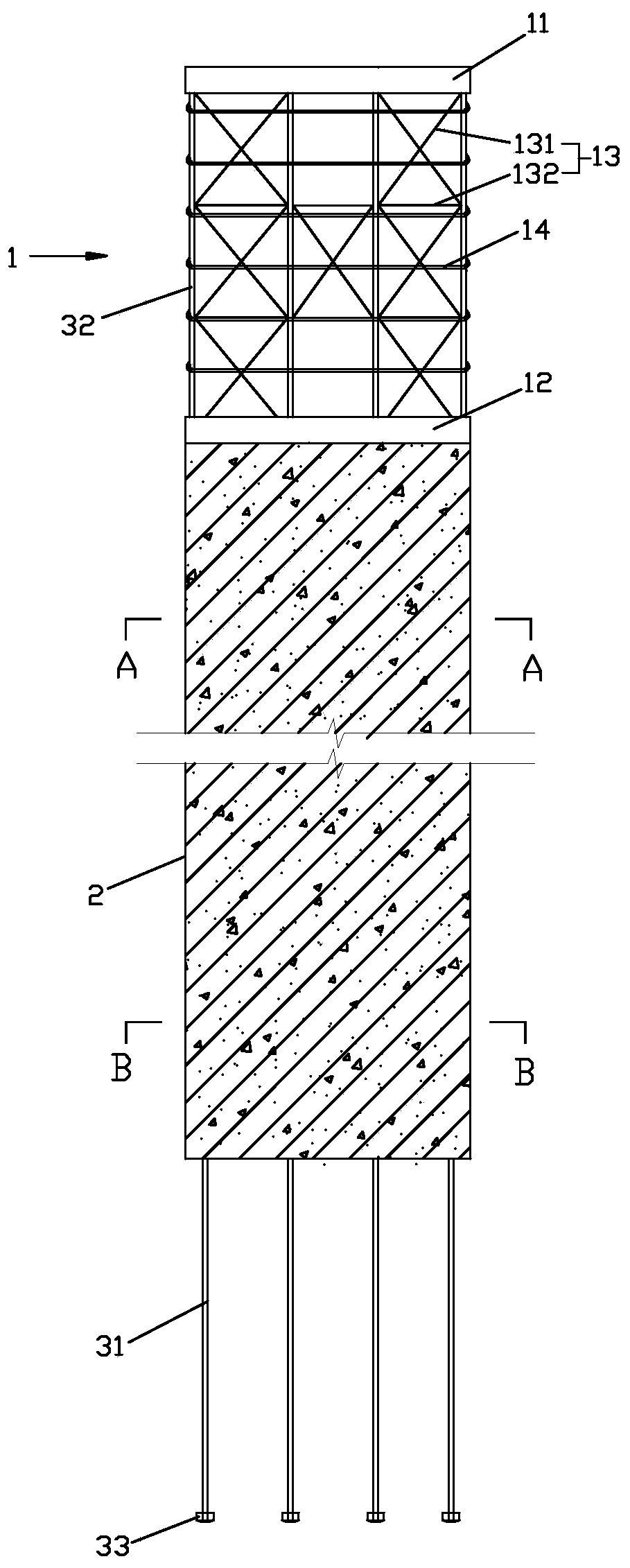

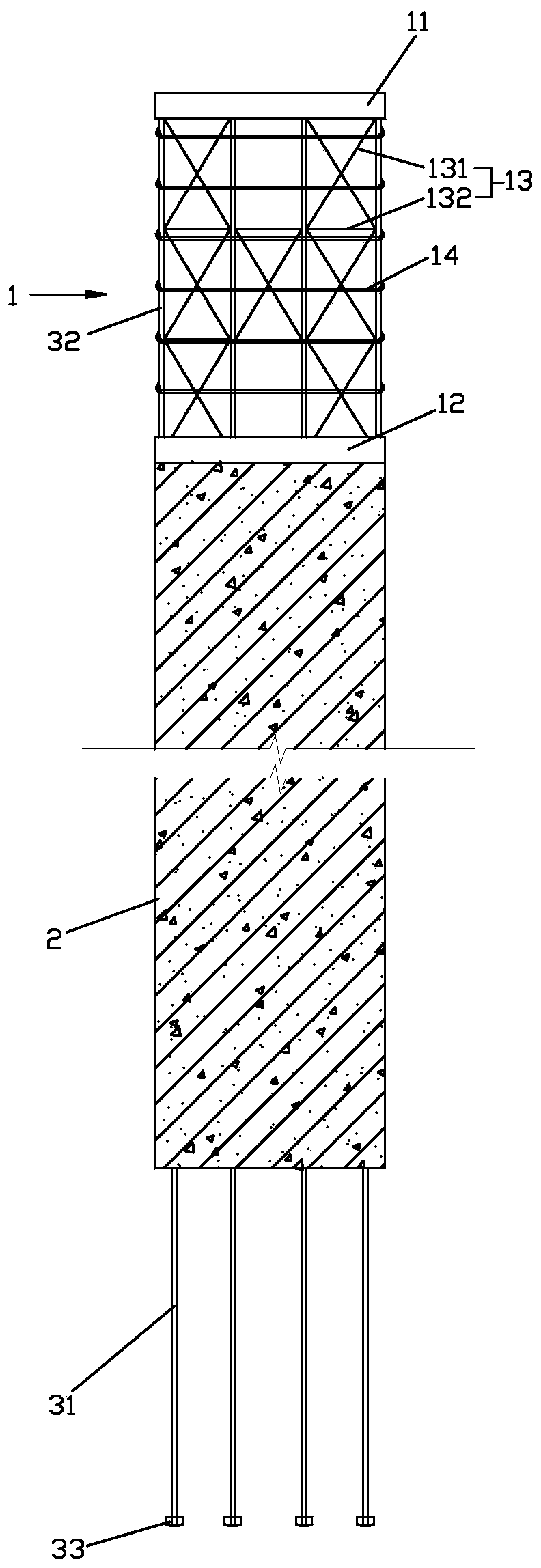

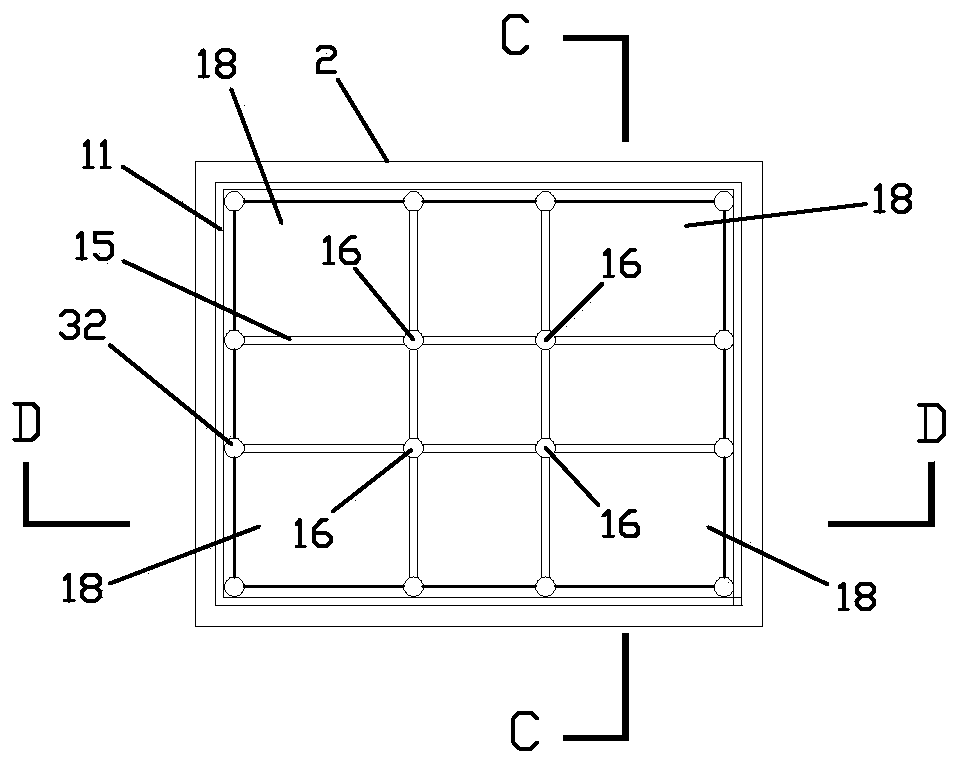

[0042] Such as Figure 1 to Figure 8 As shown, the prefabricated column of this embodiment includes a column body 2, twelve longitudinal stress bars 3 embedded in the column body 2 and a plurality of column internal stirrup bars 4, and the longitudinal stress bars 3 are along the side of the column body. Evenly distributed, there is a certain distance between the longitudinally st...

Embodiment 2

[0054] Such as Figure 11 to Figure 15 As shown, the difference between the prefabricated column of Embodiment 2 and the prefabricated column of Embodiment 1 mainly lies in that the steel truss connection structure of the prefabricated column of Embodiment 2 is provided with only one longitudinal supporting steel bar 16, and the longitudinal supporting steel bar 16 is arranged on the longitudinal stressed steel bar 3 in the middle of the space surrounded by the part 32 that passes through the upper end of the cylinder. In addition, the steel trusses 18 formed at the four corners are respectively connected by four groups of steel bar groups 13 arranged longitudinally, one horizontal steel bar 132 is shared between the upper and lower adjacent steel bar groups 13, and only two sets of steel bar groups 13 are passed between the steel trusses 18. Connect the middle. In addition, the length of the part where the longitudinally stressed reinforcing bar 3 passes out from the two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com