Production process for efficiently and centrifugally casting nodular cast iron pipe through hot mold

A technology of ductile iron pipe and centrifugal casting, which is applied in the field of ductile iron pipe casting and ductile iron pipe thermal mold centrifugal casting, which can solve the problems that cannot meet the needs of the market, so as to speed up the solidification time, increase the demoulding temperature, and realize production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A high-efficiency thermal mold centrifugal casting ductile iron pipe production process, comprising the following steps:

[0025] S1 Spray paint on the inner wall of the metal pipe mold: control the wall thickness of the pipe mold to 70mm, the temperature of the pipe mold is within 110-130°C, preferably 120°C, and then move back and forth through the spraying trolley with a cleaning brush and a spray rod, and use the nozzle to spray on the metal pipe mold. The inner wall of the pipe mold is sprayed with heat-insulating paint with a thickness of 0.5-0.8mm. The function of the paint is to protect the pipe mold and slow down the cooling rate of molten iron so that cementite does not appear in the cast pipe structure.

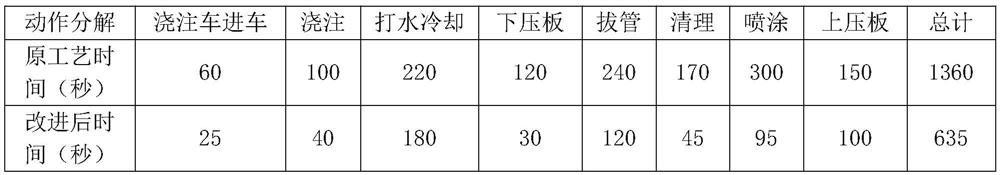

[0026] In the original production process, the cleaning brush is generally used to enter the inside of the pipe mold for a back and forth cleaning, and then use the spraying rod (the cleaning brush is on the spraying rod) to enter the inside of the pipe mold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com