Concrete circulation conveying system with hanging cages

A cyclic conveying and concrete technology, which is applied in the field of concrete continuous pouring system and hanging tank conveying system, can solve the problems of low work efficiency and long travel time, and achieve the effect of improving efficiency, improving work efficiency and shortening the pouring cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

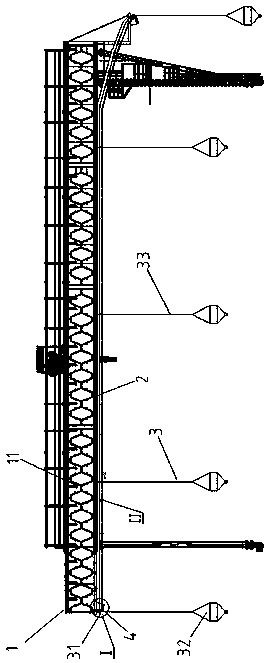

[0017] Such as figure 1 As shown, the present embodiment is installed on a 60-ton gantry crane 1, and includes an annular circulation track 2, eight hanging tank suspension devices 3 and a transmission device 4. The two straight sections 22 of the arc section 21 are parallel to the girder 11 of the gantry crane. Except that one end of the circular circulation track 2 above the concrete pouring surface slopes down, the rest of the circular circulation track 1 is in a horizontal state. The circular circulation track 2 is located at the lower side of the beam 11 of the gantry crane and is made of I-beam or H-beam. Or the ring-shaped circulating track 2 has one end high and the other end low and inclined to set, so as to facilitate the pouring of larger concrete members.

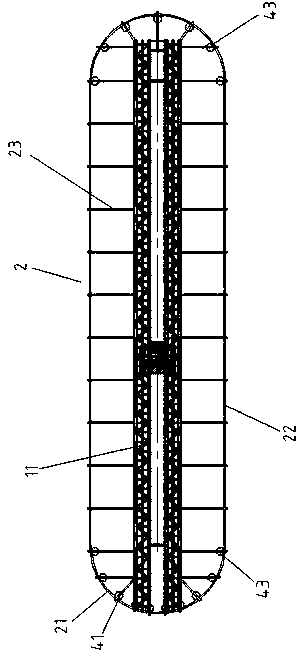

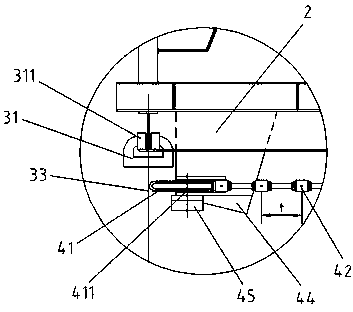

[0018] Such as figure 2 As shown, the inner side of the circular circulation track 2 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com