A shelling valve with reduced fluid resistance

A technology of fluid resistance and flaps, which is applied in the direction of offensive equipment, rocket launchers, weapon types, etc., can solve the problems of large differences in flap resistance, not easy to bend and deform, and the flaps are out of interference, etc., to improve underwater launch Speed, reduce bending deformation, increase the effect of launching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to illustrate the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

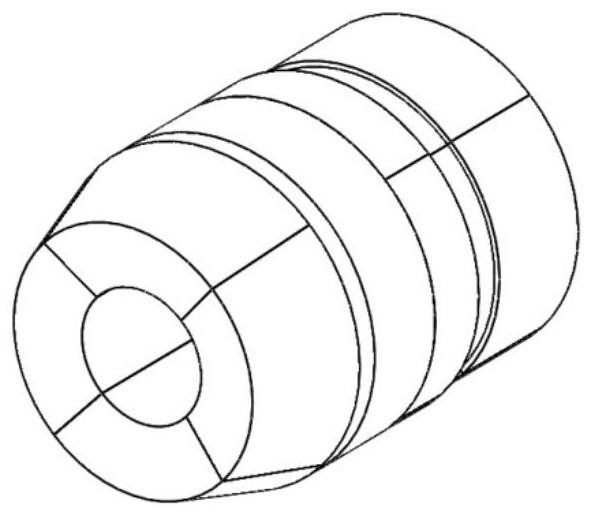

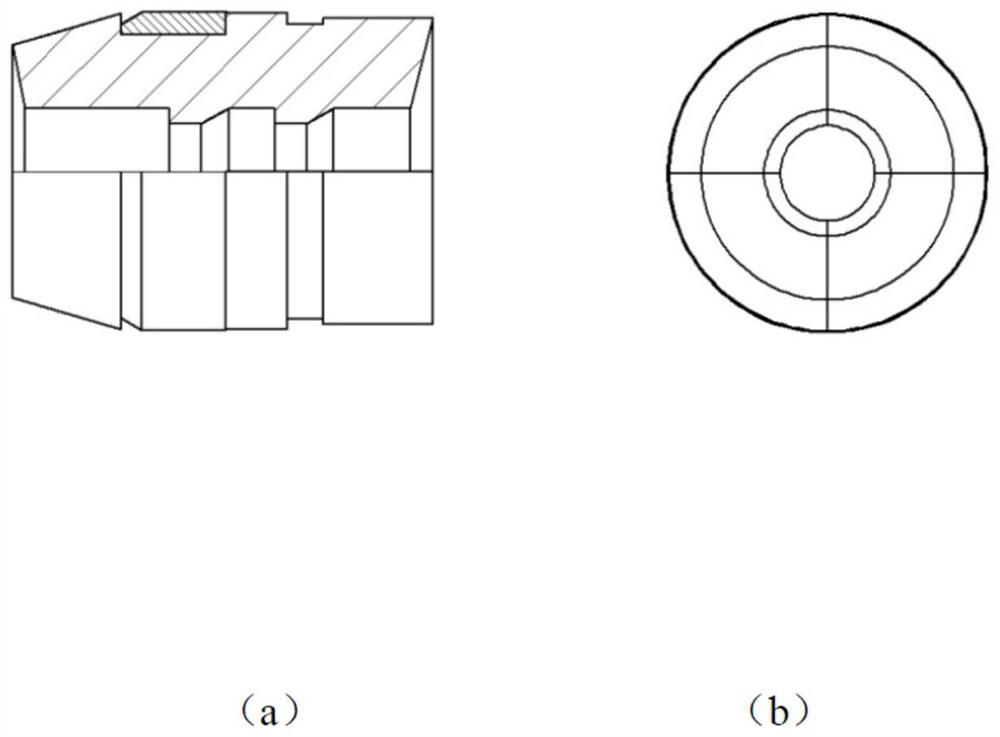

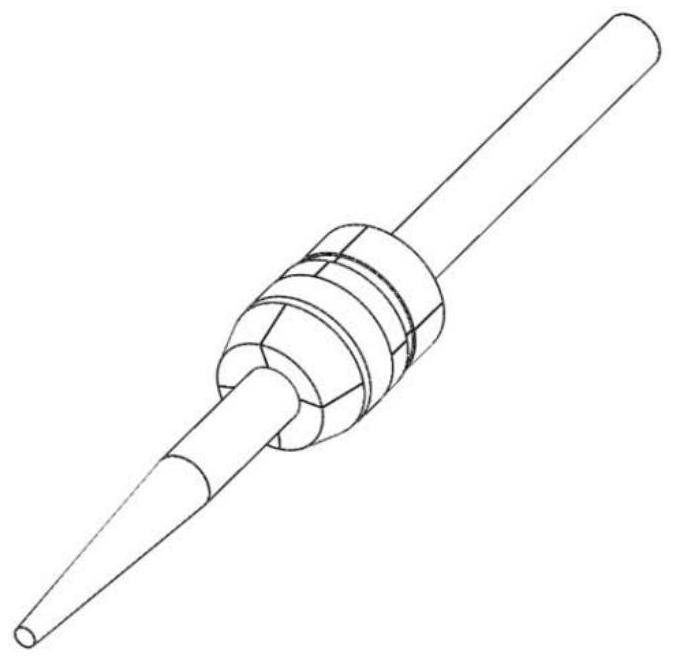

[0023] refer to figure 1 , image 3 , The shelling flap of the present invention which reduces fluid resistance is composed of 4 flaps, which cooperate with projectiles through the multi-section bosses in the internal through holes, and are fixed by matching with elastic belts.

[0024] refer to figure 1 , figure 2 with image 3 , The shelling valve with reduced fluid resistance of the present invention has a frustum-shaped front end, and compared with ordinary cylindrical valves, the force-bearing surface of the front end is reduced by more than 40%. The front end faces inward with a certain inclination angle, and there is an outward radial force under the action of water flow, and the front end of the card flap is easy to separate outward after being discharged from the bore.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com