Visual measurement method and device

A technology for visual measurement and products to be tested, applied in the field of visual measurement, can solve the problems of manufacturing difficulty, manufacturing accuracy, manufacturing cost, and increase in equipment volume, and achieve the effects of easy implementation, high detection efficiency, and low system construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

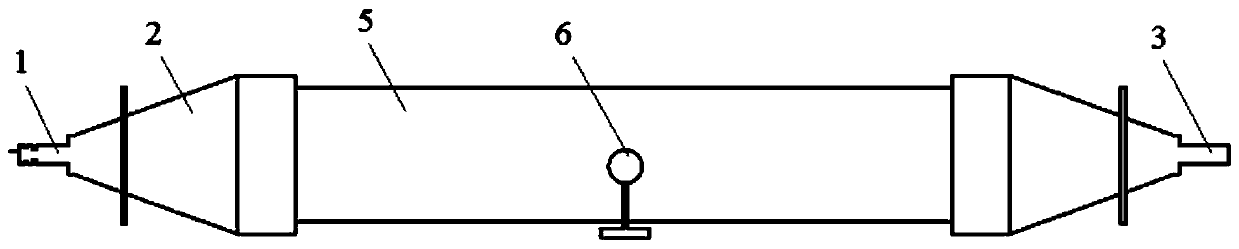

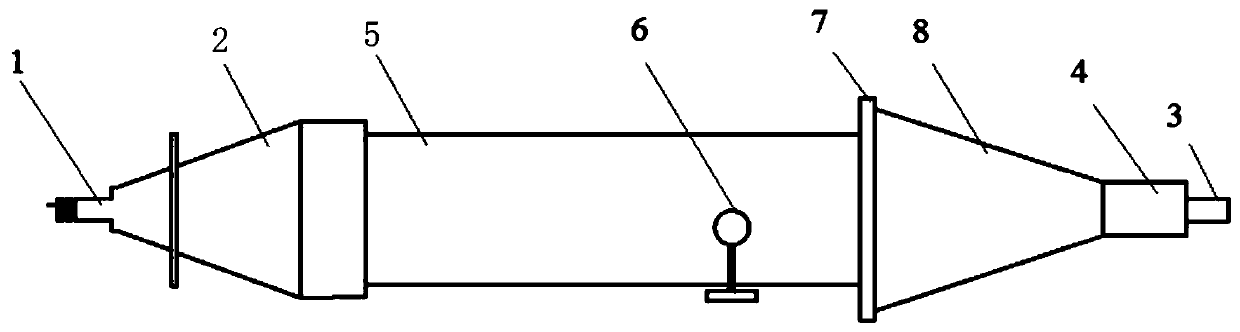

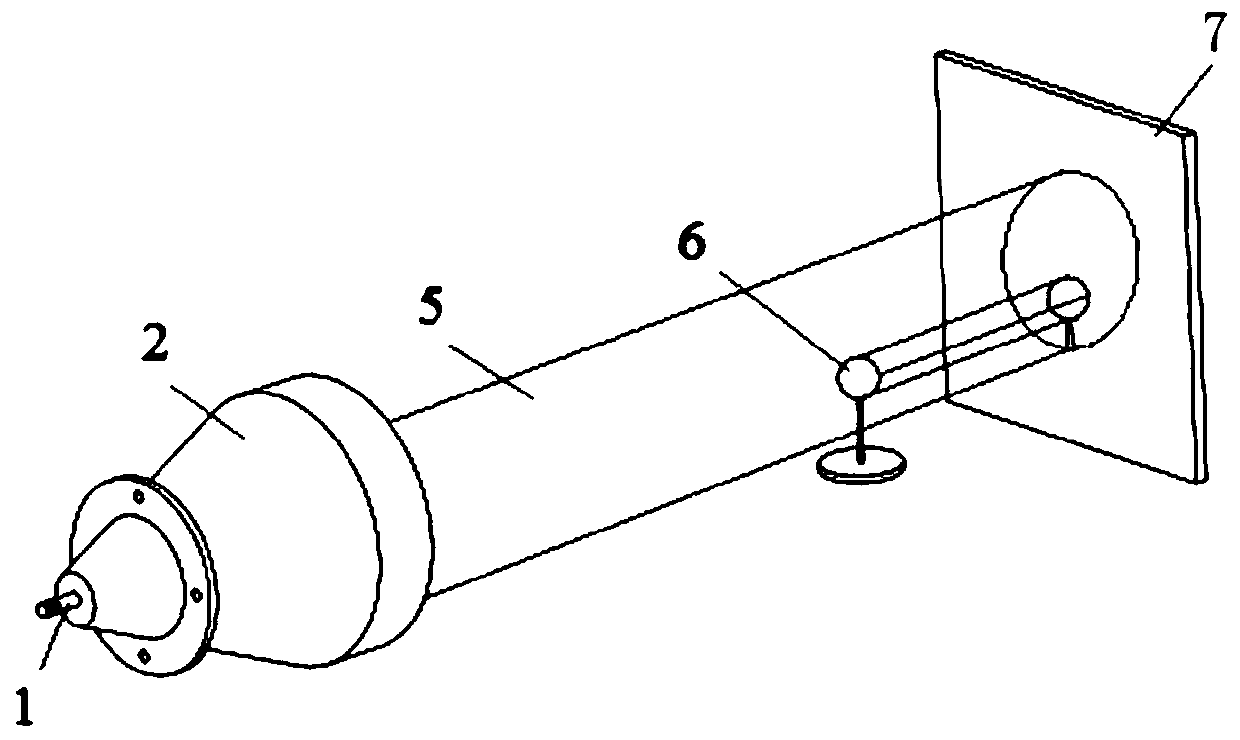

[0029] Aiming at the problems existing in the prior art, the present invention provides a visual measurement method and device, the following in conjunction with the attached Figures 2 to 5 The present invention is described in detail.

[0030] The visual measurement method and device include a telecentric lighting source, the telecentric lighting source is used to generate parallel lighting beams; a projection screen, the front of the projection screen is used to receive the contour projection generated after the telecentric lighting source irradiates the part; The lens is used for converging the projection of the object outline on the projection screen onto the target surface of the camera; the camera is fixedly installed on the back of the projection scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com