A composite material reinforced wall plate shear test piece

A technology of reinforced wall panels and composite materials, applied in the direction of analyzing materials, using stable shear force to test the strength of materials, instruments, etc., can solve the problem of delamination between the bottom edge of the long stringer and the skin, and the failure to achieve the test purpose , prone to problems such as delamination, to achieve uniform distribution of shear stress, prevent additional bending, and avoid sudden changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

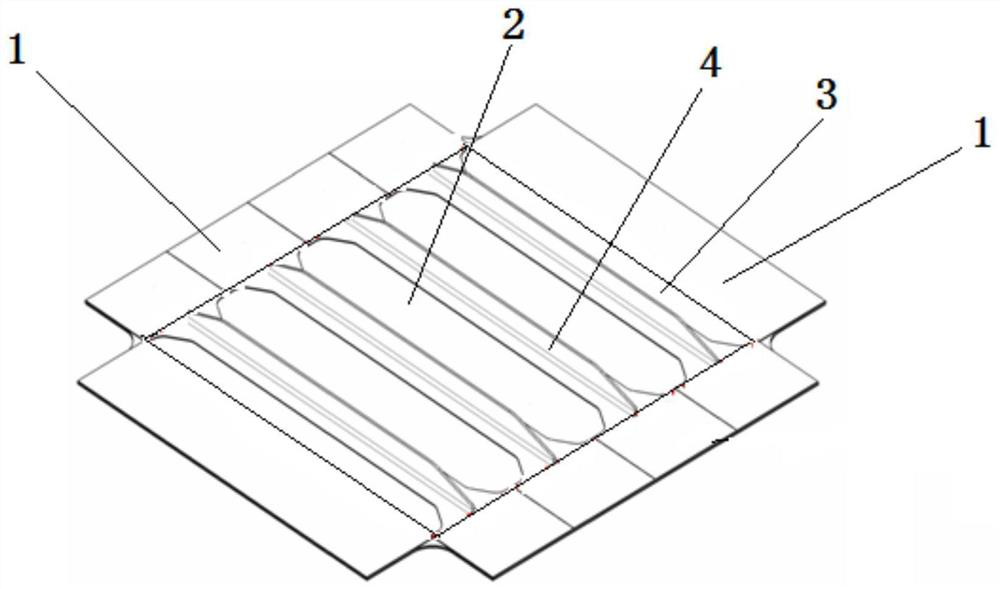

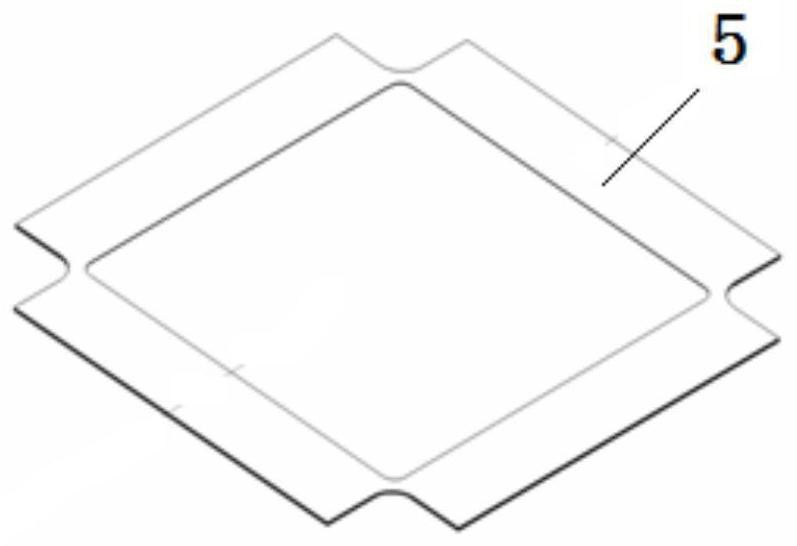

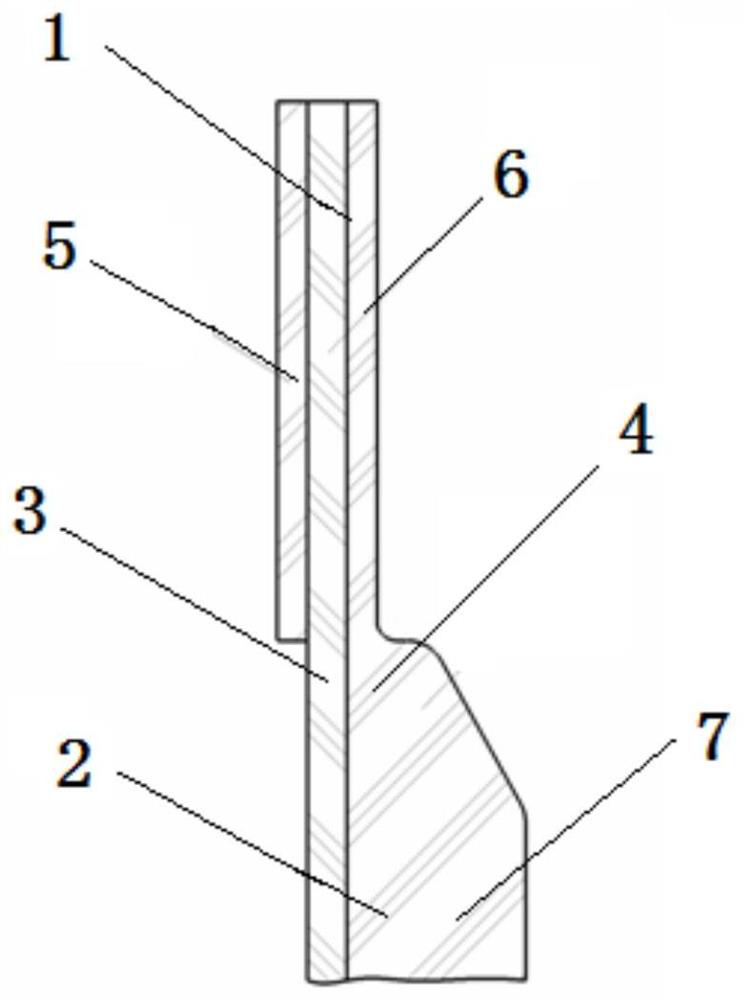

[0014] Referring to the accompanying drawings, the composite material reinforced wall plate shear test piece provided by the application, the body of the test piece is a square composite material reinforced wall plate, and the periphery of the test piece is the loading area 1 for test clamping, and the test piece The center of the center is the test assessment area 2, the test assessment area 2 contains a skin 3 and a plurality of long stringers 4 integrally formed with the skin 3, and the long strings 4 contain a bottom edge 6 attached to the skin 1 And the flange 7 perpendicular to the bottom edge, the four sides of the skin of the examination area protrude and extend respectively to form the matrix layer of the loading area, and a layer of reinforcement is provided on the upper surface of the skin matrix layer of the loading area on both sides parallel to the long stringer Layer 8, the reinforcement layer 8 is equivalent to the thickness of the bottom edge 6 of the stringer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com