Glass fiber manufacturing industrial equipment fault sequence determination method and system

A technology of industrial equipment and glass fiber, which is applied in the field of determining the fault sequence of industrial equipment in the glass fiber manufacturing industry and the system, and can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

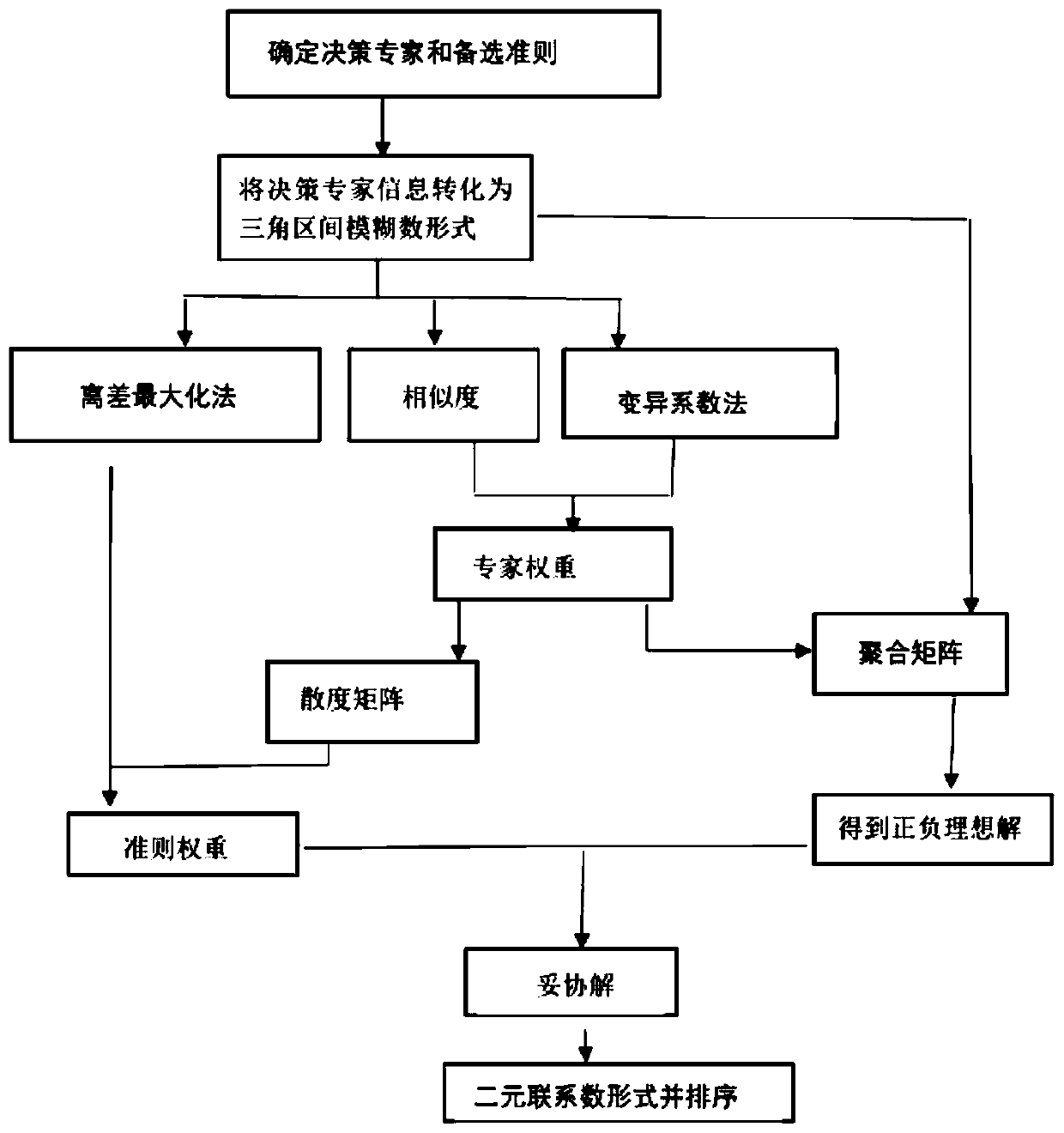

[0055] See attached figure 1 As shown, this embodiment discloses a method for determining the fault sequence of industrial equipment in the glass fiber manufacturing industry, including:

[0056] (1) Transform the evaluation information of the decision-making experts into the corresponding triangular interval fuzzy number form by using the intelligence set in the language; that is, transform the language description of the fault information of the glass fiber manufacturing industrial equipment given by the decision-making experts into the corresponding triangular interval fuzzy number form form.

[0057] In the data model formula, the data related to the glass manufacturing industry is substituted into the model, so the obtained result is a fault determination method for the fault sequence of industrial equipment in the glass fiber manufacturing industry.

[0058] (2) Using the coefficient of variation method based on similarity to calculate the weight of decision-making expe...

Embodiment 2

[0122] The purpose of this embodiment is to provide a system for determining the fault sequence of industrial equipment in the glass fiber manufacturing industry, which is implemented based on a server, including:

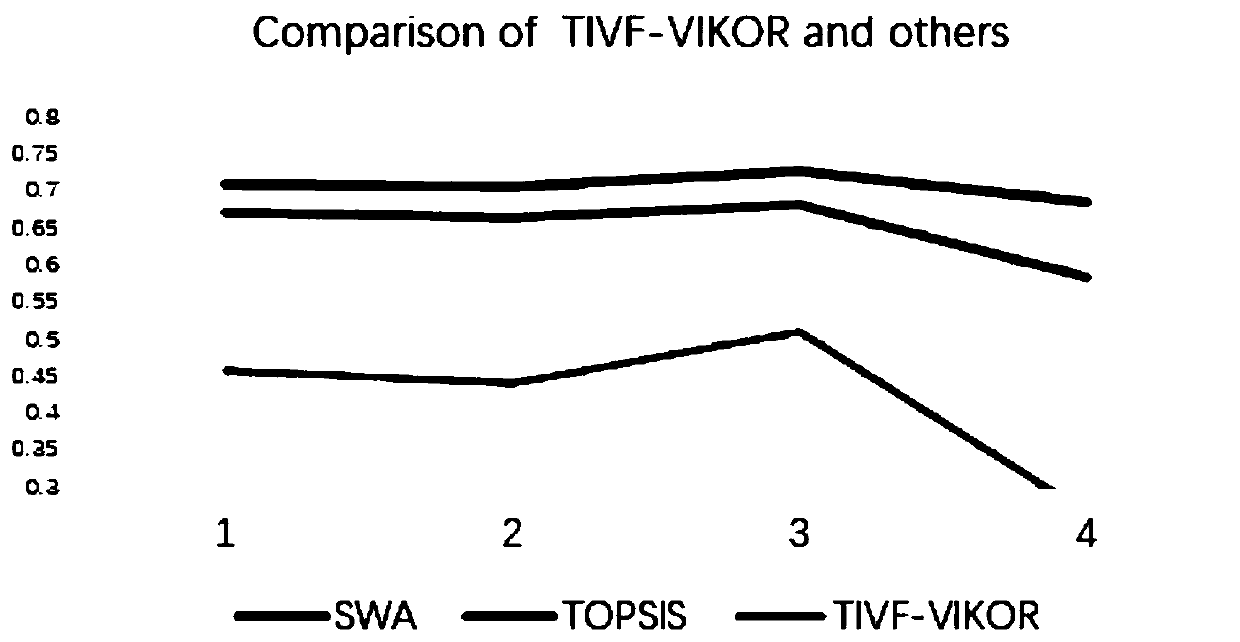

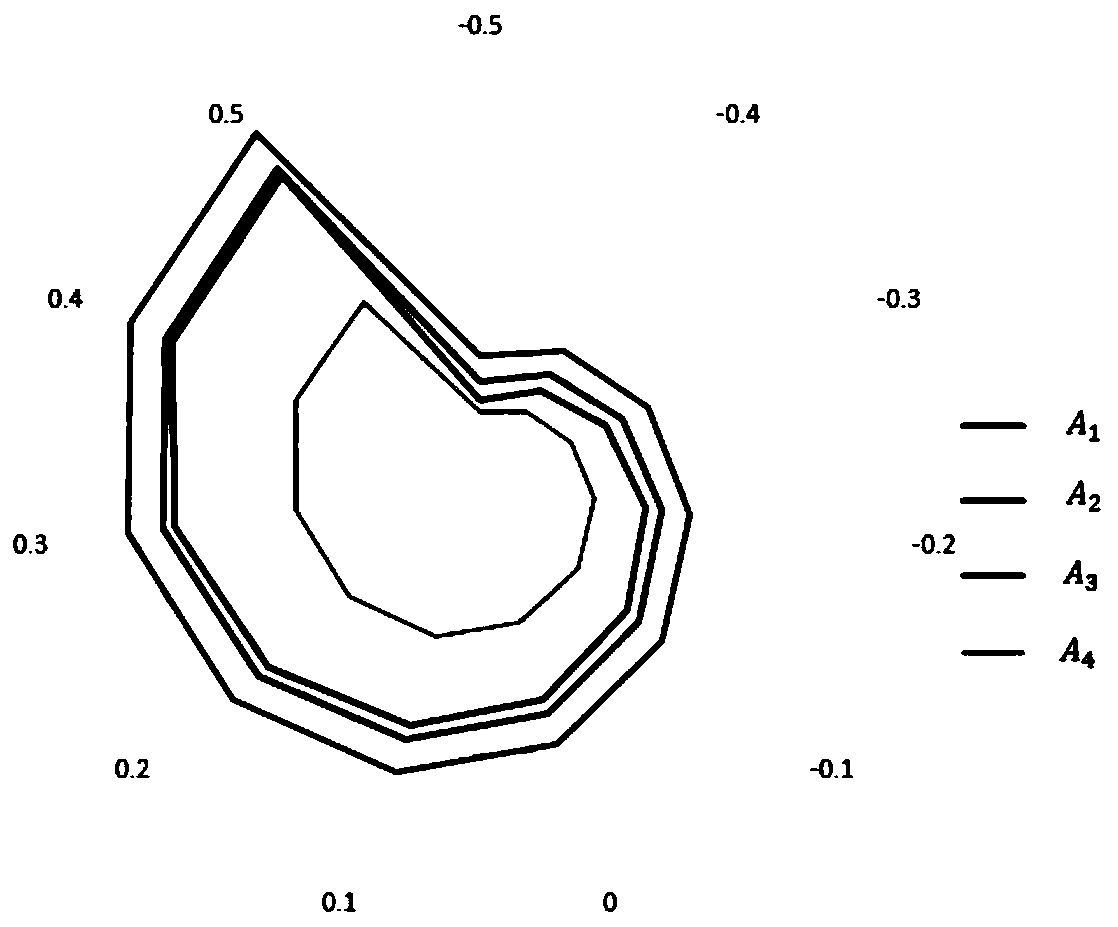

[0123] After obtaining the fault information of industrial equipment, through the decision-making expert group, the fault information is transformed into corresponding linguistic variables, and the linguistic variables are further transformed into triangular interval fuzzy numbers. The triangular interval fuzzy number representing the fault of the industrial equipment in the glass fiber manufacturing industry is brought into the algorithm proposed in this paper, and it is closely combined with the algorithm. According to the fault data of the industrial equipment in the glass fiber manufacturing industry, the model is solved step by step, and then the fault location is calculated. After sorting, the optimal solution is obtained.

[0124] The order of the determined...

Embodiment 3

[0126] A computer device, comprising a memory, a processor, and a computer program stored on the memory and operable on the processor, wherein the processor implements the following steps when executing the program:

[0127] Obtain fault information of industrial equipment in the fiberglass manufacturing industry;

[0128] Introduce the concept of intelligence set in the language, use relevant language variables to describe the evaluation information of decision-making experts, and express the complex equipment failure information through the corresponding fuzzy numbers;

[0129] Calculate expert weights and criterion weights, express decision information in the form of "triangular interval fuzzy numbers", combine with VIKOR method, use binary connection number to obtain a compromise solution, and select the optimal solution when industrial equipment failure occurs under the action of multiple criteria alternatives for .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com