Semiconductor laser photoelectric detector die bonding clamp and die bonding method

A technology of photoelectric detectors and lasers, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of easy deformation of springs, poor clamping accuracy of tube holders, and inconvenient operation, so as to increase the loading capacity and facilitate the replacement of tube holders , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

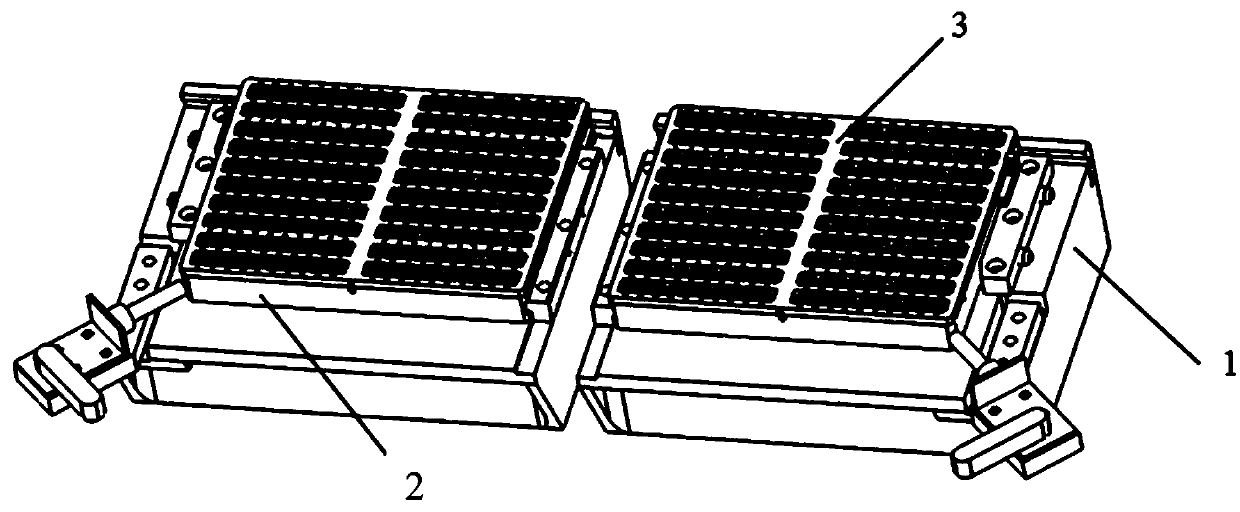

Embodiment 1

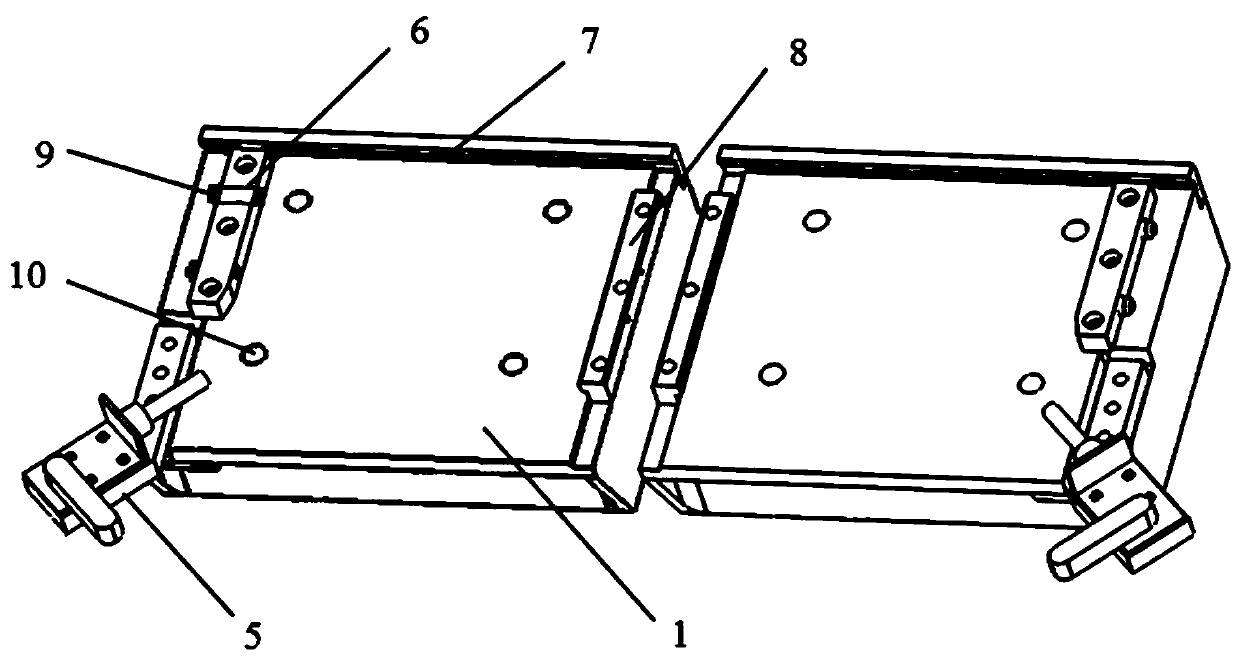

[0043] The fixing mechanism may have the following structure, which includes several installation holes 10 arranged longitudinally on the base 1, and the bolts pass through the installation holes 10 and then screwed onto the photodetector automatic crystal bonding equipment.

Embodiment 2

[0045] The positioning mechanism may have the following structure, which includes a stopper I 7 arranged horizontally at the rear end of the base 1, a stopper II 8 arranged vertically at the right end of the base 1, and a stopper II 8 arranged vertically at the left end of the base 1 The positioning block 6 and the toggle clamp 5 arranged at the lower left corner of the base 1 are screwed with a fixing screw 9 in the positioning block 6 . After the tube bases 22 are inserted in the tube base positioning holes 12 on each tube base mounting strip 18 in the tray 2, the tray 2 is placed on the base 1 so that the upper end of the tray 2 is aligned with the stopper I 7 contact, the left end of the tray 2 is in contact with the positioning block 6, and then by rotating the fixing screw 9, the head end of the fixing screw 9 drives the tray 2 towards the block II 8, and the tray is held by the toggle clamp 5 The lower left end of the tray 2 is locked, and finally the upper end of the t...

Embodiment 3

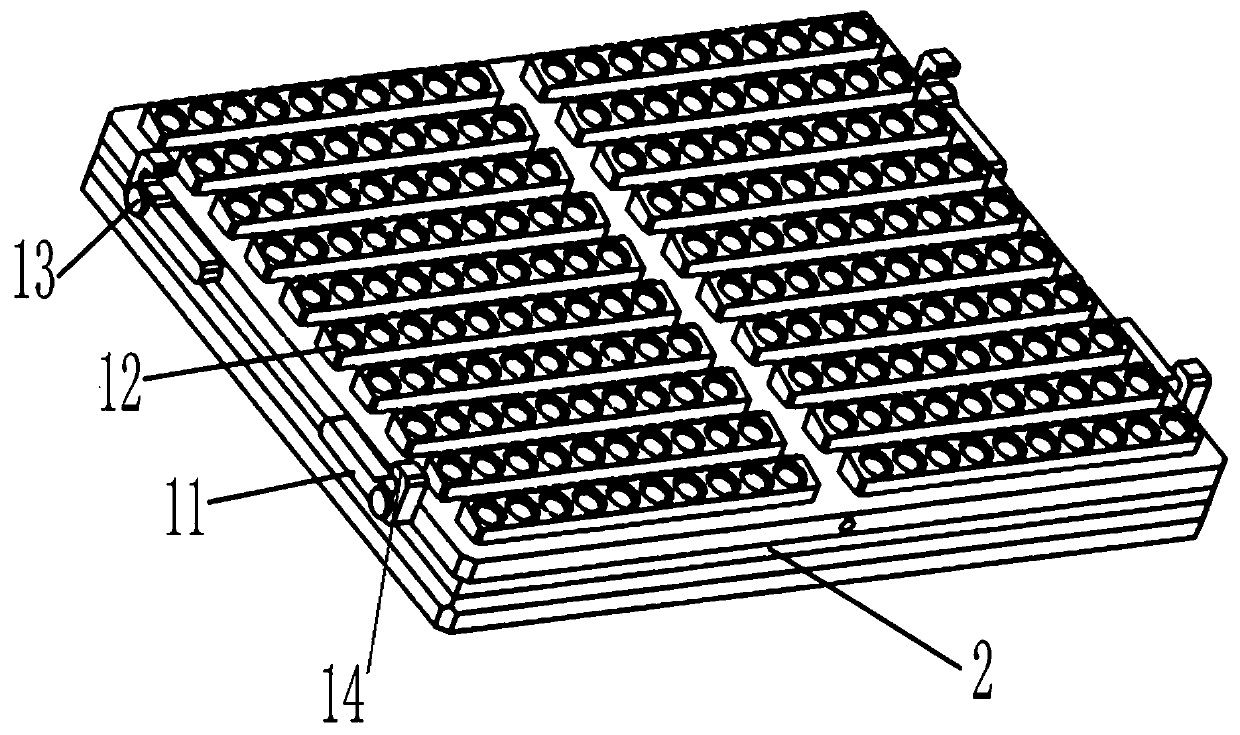

[0047] The cover plate fixing mechanism can be the following structure, which includes pins 19 and driving rods 11 that are horizontally arranged on the left and right sides of the cover plate 3 respectively. A hook head 14 is provided, and when the driving lever 11 is rotated to a horizontal state, the hook head 14 is hooked on the corresponding pin 19 . After the cover plate 3 is fastened to the material tray 2, move the lever 11 downward to make it rotate to a horizontal state, the hook head 14 is hooked on the pin 19 to lock and fix the cover plate 3, and the operation is simple , when unlocking, you only need to reversely turn the lever 11 to get final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com