Ophthalmic precise injector

A precise, ophthalmic technology, applied in the field of medical devices, can solve the problems of incomplete elimination of residues, poor sealing and sliding performance, and not simple structure, and achieves reduction of liquid residues, good sliding performance and sealing performance, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solution of the present invention, its specific implementation will be described in detail below in conjunction with the accompanying drawings:

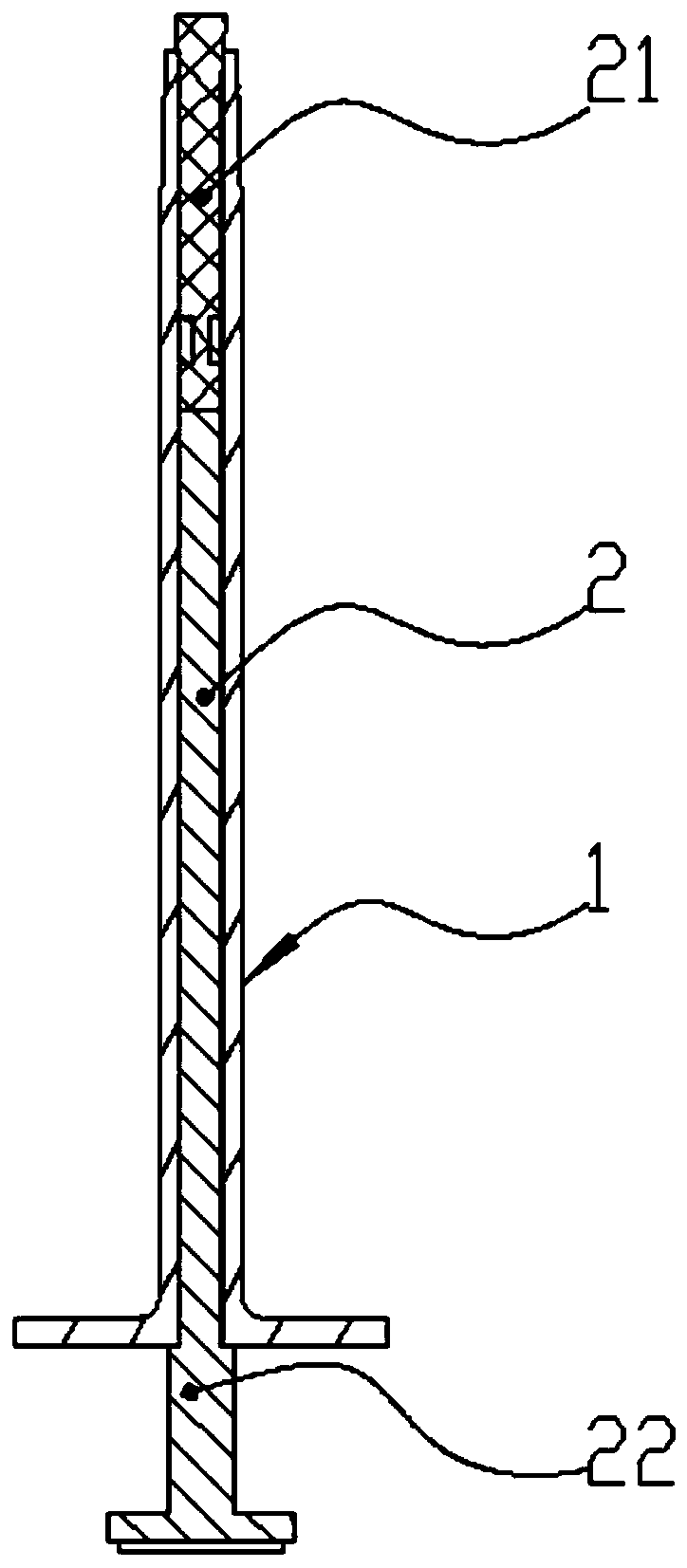

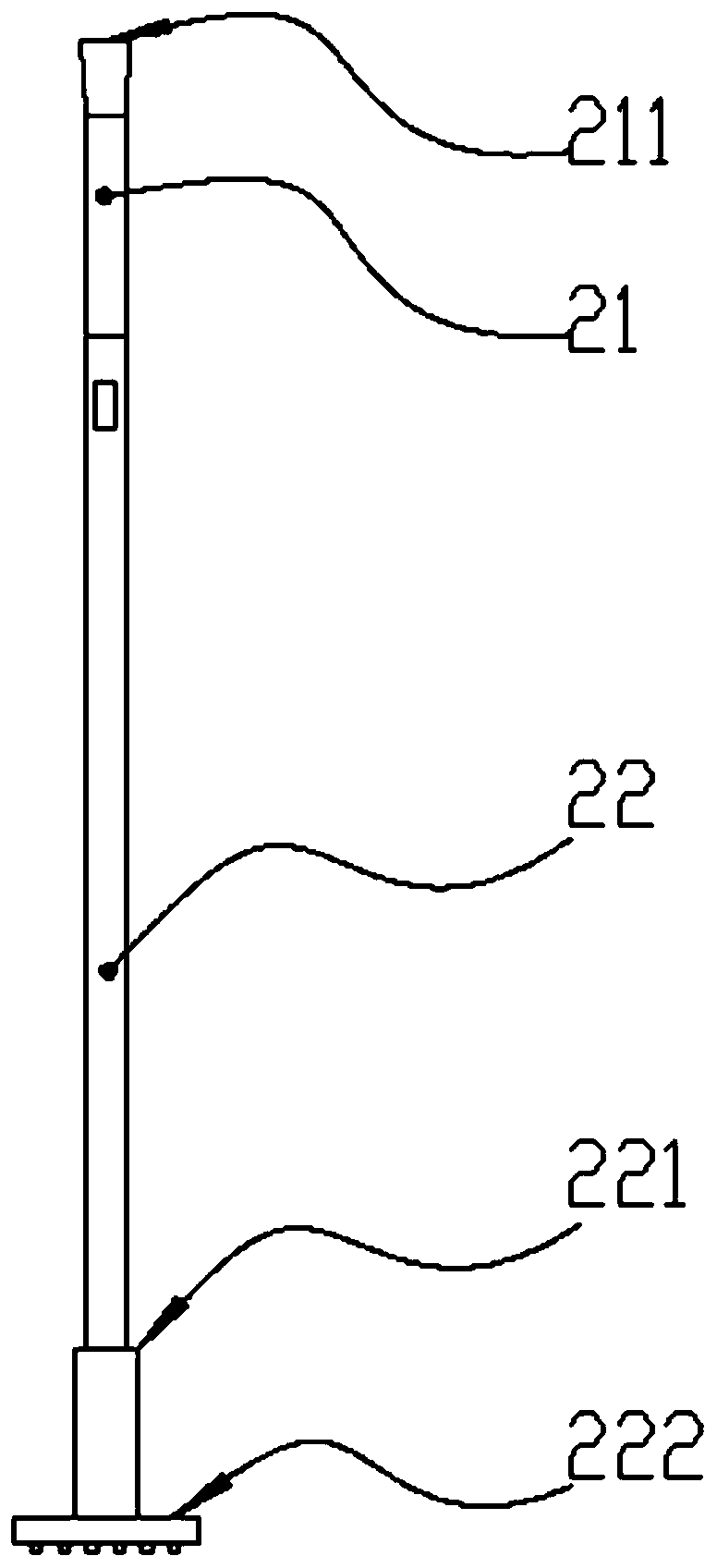

[0032] see Figure 1 to Figure 11 , the best embodiment of the present invention, a precision injector for ophthalmology, including a jacket 1 and a core rod 2 inserted in it, the core rod 2 is divided into two sections, which are respectively the front section 21 of the core rod and the rear part of the core rod Segment 22 , the rear end of the core rod front segment 21 and the front end of the core rod rear segment 22 are connected together through the radial dovetail tenon groove structure 3 .

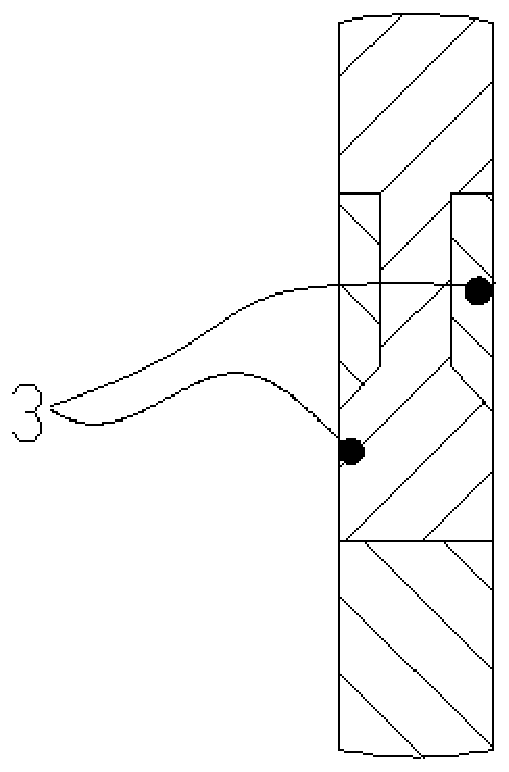

[0033] see again image 3 and Figure 4 , the radial dovetail groove structure 3 includes a shaft 31, a dovetail 32, a shaft hole 33 matched with the shaft, and a dovetail groove 34 matched with the dovetail; the shaft 31 is arranged at the rear end of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com