Pipeline welding heating device as well as welding device and method

A heating device and welding device technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of increasing defects, failing to meet the requirements of regulations and specifications, and unable to heat the welding parts, so as to ensure the welding quality and guarantee Preheat temperature, ensure the effect of temperature requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

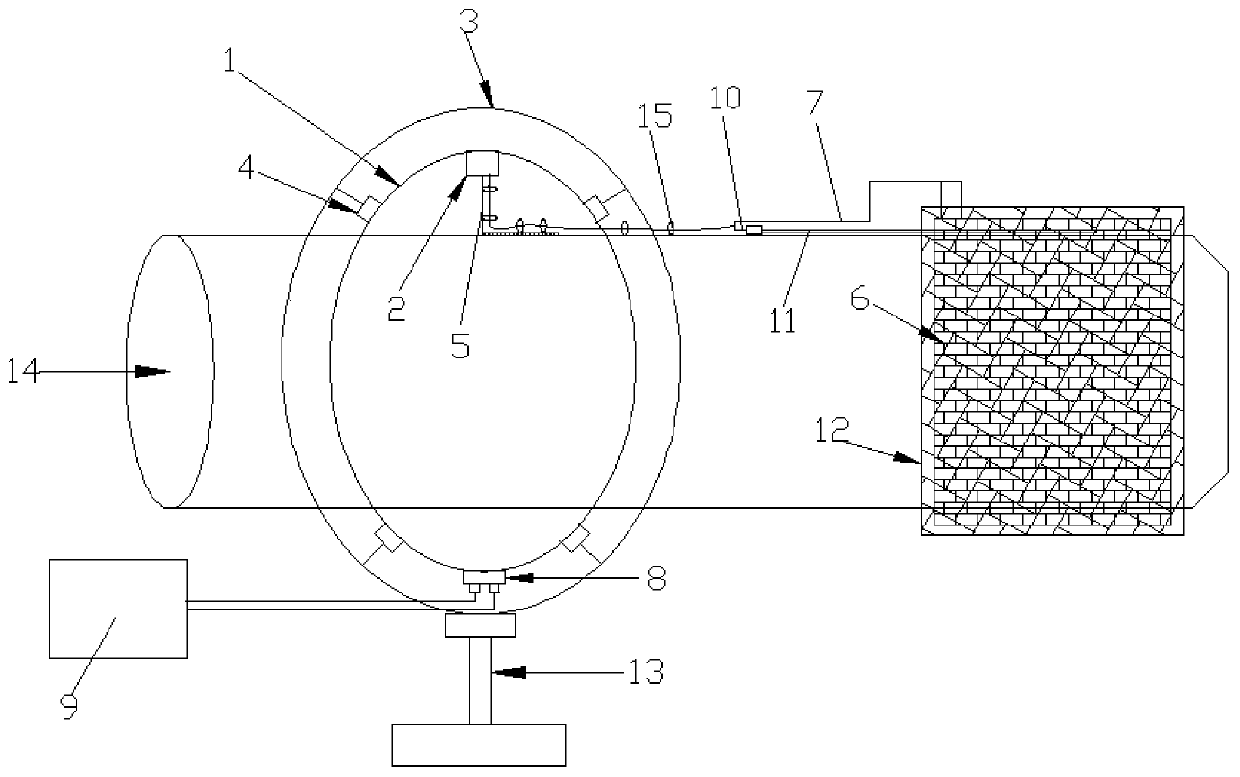

[0051] This embodiment discloses a pipe welding device, which includes a pipe automatic welding machine and two sets of pipe welding heating devices described in Embodiment 1. The sliding contact wires and brackets of the two sets of pipe welding heating devices are respectively arranged on the pipes to be welded. At both ends of the first and last ends, the sliding contact line, the bracket and the pipeline to be welded are arranged coaxially. When in use, the first and last ends of the pipeline pass through the sliding contact line.

Embodiment 3

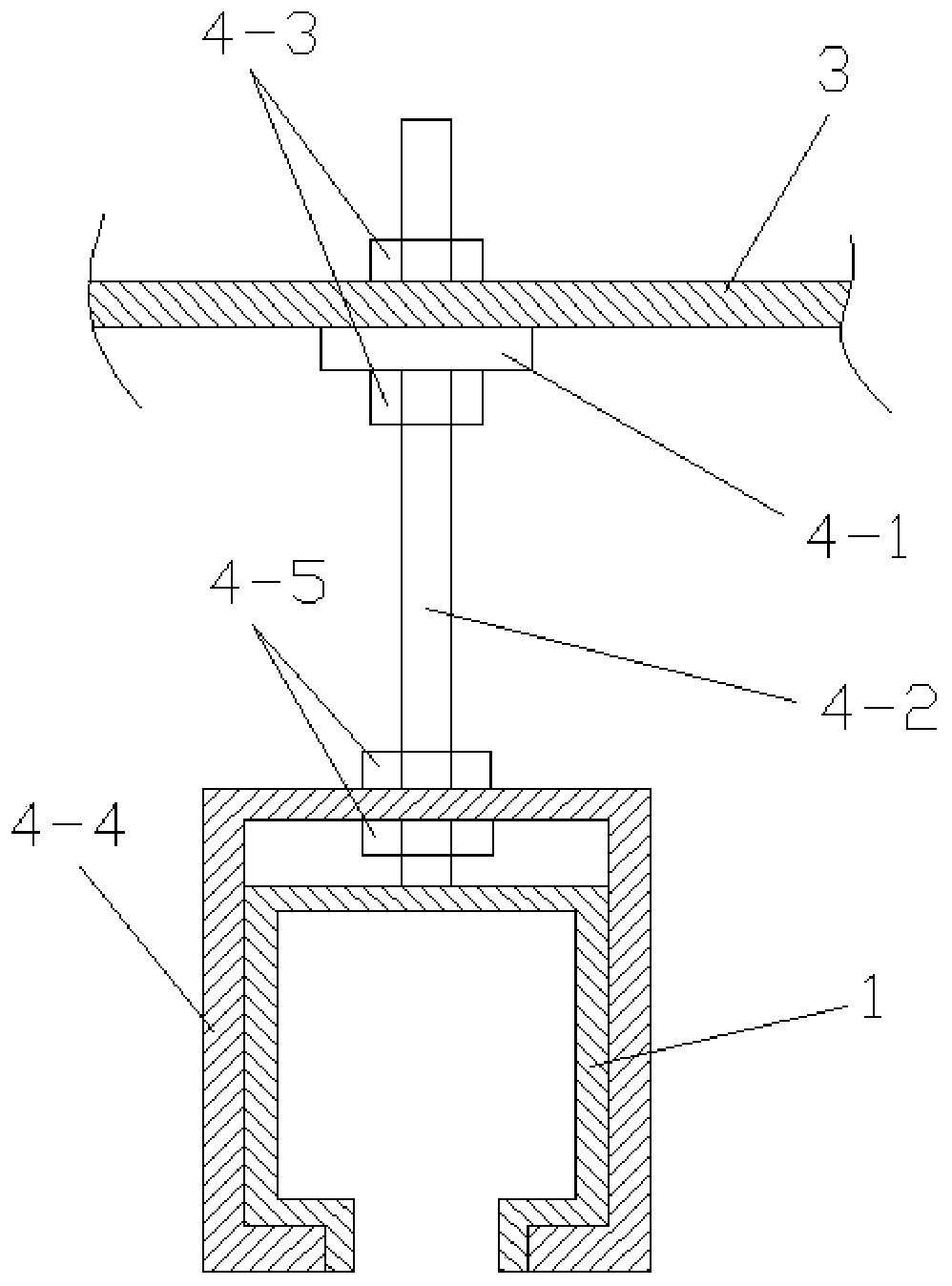

[0053] This embodiment discloses a working method of a pipeline welding device: Figure 5 As shown, the pipeline 14 is placed on the automatic welding machine, and the pipeline welding heating device is placed on the pipeline automatic welding machine. Pass through the sliding contact line, select a suitable connecting plate to connect with the current collector, attach the connecting plate to the pipeline to be welded by magnets, fix the thermocouple on the pipeline to be welded by binding iron wire, and the distance between the thermocouple and the groove at the end of the pipeline is 20mm -30mm, then wrap the resistance ceramic heater on the outer peripheral surface of the end of the pipe, and the thermocouple extends between the resistance ceramic heater and the pipe, that is, the thermocouple extends into the heating area of the resistance ceramic heater, and the resistance ceramic heater After installation, wrap the thermal insulation blanket around the outer periphery...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com