Clamp for pipeline clamping

A pipe and fixture technology, applied in the field of pipe clamping equipment, achieves the effect of accurate and stable three-point positioning and stable clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

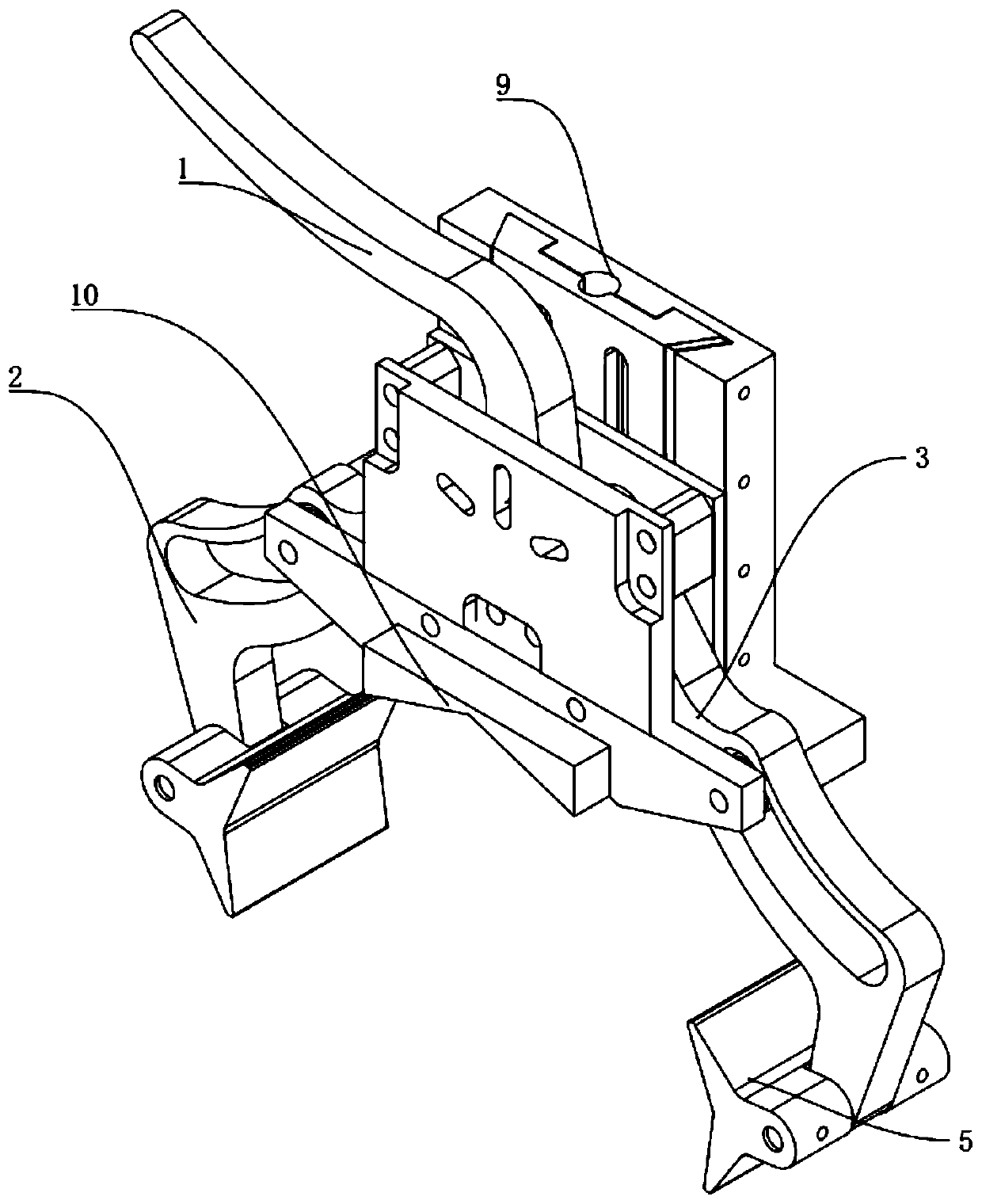

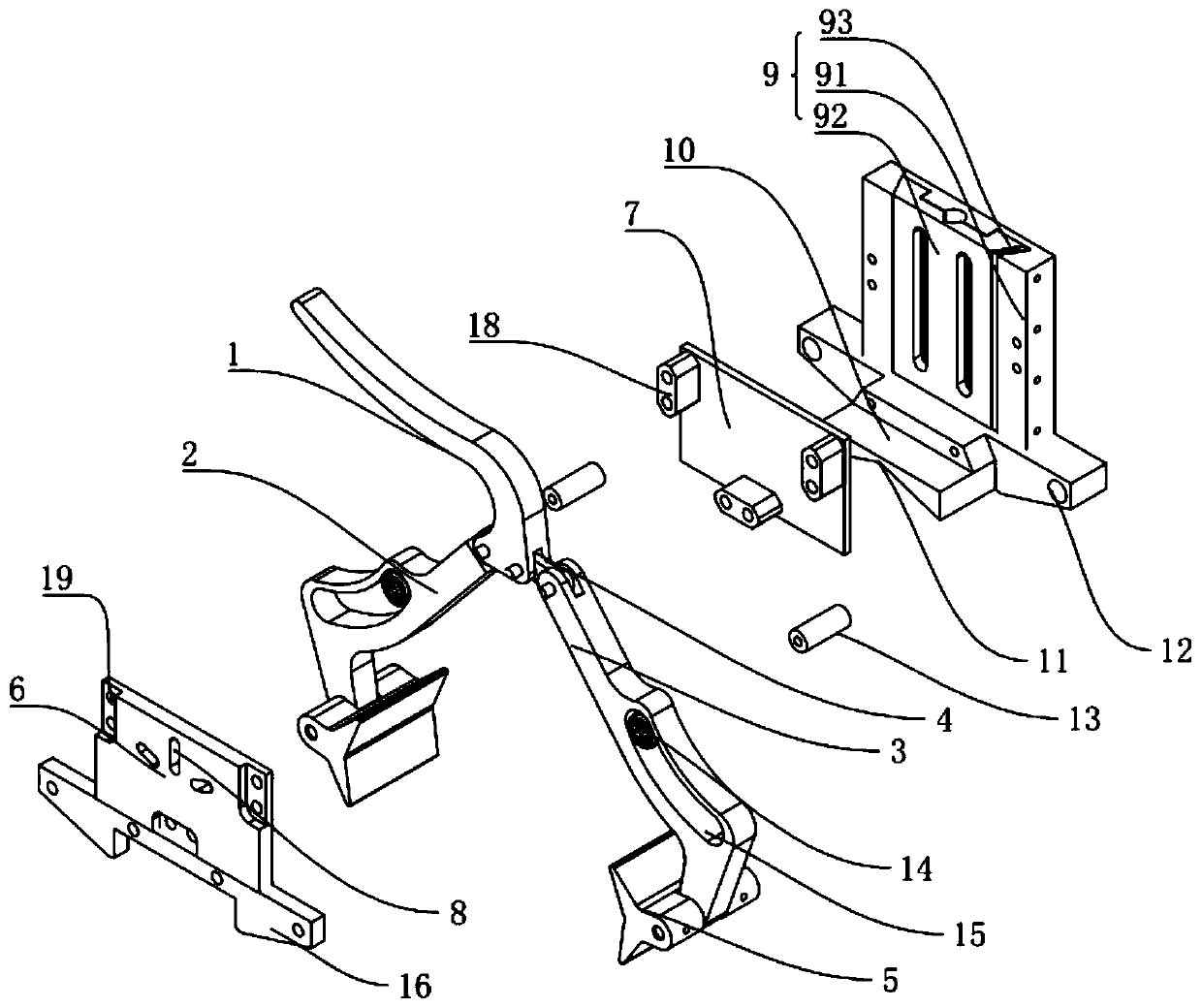

[0017] Such as figure 1 and 2 As shown, a clamp for pipe clamping includes a clamping handle 1, clamping rod one 2 and clamping rod two 3, a pair of clamping jaws 5, a front wall 6 and a rear wall 7, a lifting assembly 9 and a stopper Block 10.

[0018] The clamping handle 1 is used to radially lock or release the pipeline, and the bottom end of the clamping handle 1 is provided with a transverse block with grooves 19 at both ends.

[0019] Clamping rod one 2 and clamping rod two 3, clamping rod one 2 is embedded in the groove 19 of the horizontal line block of clamping handle 1, and is hinged with clamping handle 1, clamping rod two 3 is hinged with transition piece 4, transition piece 4 Embedded in the groove 19 at one end of the transverse block of the clamping handle 1, and hinged with the clamping handle 1, pin shafts are installed at each of the above-mentioned hinges and a certain length is reserved for the pin shafts, and the reserved length of the pin shafts is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com