Automatic feeding device for material conveying

A technology for feeding equipment and materials, which is applied to conveyor objects, transportation and packaging, loading/unloading, etc., can solve the problems of large size, poor labor-saving effect, and heavy weight of bolt feeders, and achieve convenient short-distance movement and labor-saving effect. Good and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

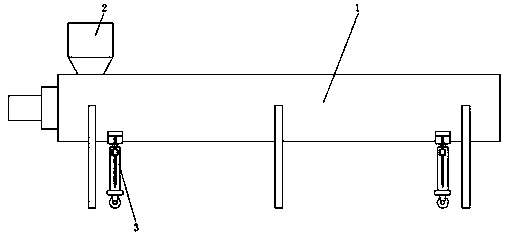

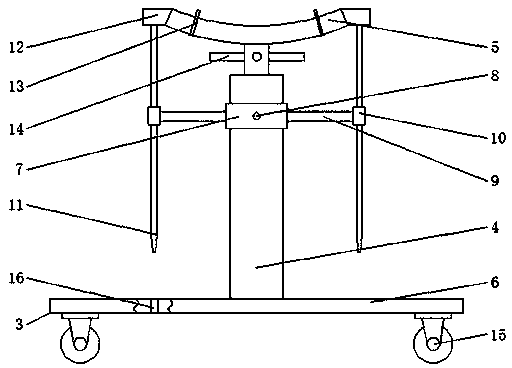

[0022] refer to Figure 1-2 , an automatic feeding device for material conveyance, comprising a screw feeder body 1 and a feed bin 2, the bottom of the screw feeder body 1 is provided with two moving mechanisms 3, and the moving mechanism 3 includes a screw jack 4, the screw jack 4 An arc-shaped plate 5 is fixedly installed on the support ring, and a bottom support plate 6 is fixedly installed on the bottom of the screw jack 4, and a collar 7 is sleeved on the screw jack 4, and four first screws 8 are arranged on the collar 7, The collar 7 is fixedly connected with the screw jack 4 by the first screw 8, the outer surface of both sides of the collar 7 is welded with a connecting crossbar 9, and one end of the connecting crossbar 9 is welded with a limit sleeve 10, and the limit sleeve 10 The limit vertical bar 11 runs through the top, and the two ends of the arc-shaped plate 5 are provided with raised blocks 12, and the raised blocks 12 are welded to the top of the limit vertic...

Embodiment 2

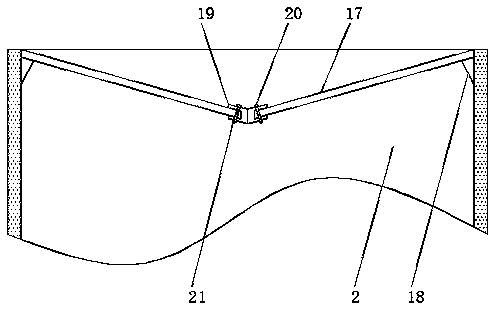

[0025] refer to Figure 1-3 , an automatic feeding device for material conveyance, comprising a screw feeder body 1 and a feed bin 2, the bottom of the screw feeder body 1 is provided with two moving mechanisms 3, and the moving mechanism 3 includes a screw jack 4, the screw jack 4 An arc-shaped plate 5 is fixedly installed on the support ring, and a bottom support plate 6 is fixedly installed on the bottom of the screw jack 4, and a collar 7 is sleeved on the screw jack 4, and four first screws 8 are arranged on the collar 7, The collar 7 is fixedly connected with the screw jack 4 by the first screw 8, the outer surface of both sides of the collar 7 is welded with a connecting crossbar 9, and one end of the connecting crossbar 9 is welded with a limit sleeve 10, and the limit sleeve 10 The limit vertical bar 11 runs through the top, and the two ends of the arc-shaped plate 5 are provided with raised blocks 12, and the raised blocks 12 are welded to the top of the limit vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com