Fused ring aromatic pigment and polymer material mixture, preparation method and downstream product thereof

A technology of polymer materials and aromatic compounds, applied in the field of pigments, can solve the problems of unavoidable waste liquid and achieve good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing a mixture of fused-ring aromatic pigments and polymer materials, comprising the following steps:

[0045] The thermoplastic macromolecule material is mixed with reactants for forming condensed ring aromatic pigments, and kneaded or extruded to obtain a mixture of condensed ring aromatic pigments and polymer materials.

[0046] Wherein, the reactants for forming the condensed-ring aromatic pigments include acid anhydride functionalized condensed-ring aromatic compound derivatives, o-diamine compounds and catalysts.

[0047] It should be noted that during the kneading or extrusion process, the anhydride-functionalized condensed-ring aromatic compound derivative and the ortho-diamine compound can react under the action of a catalyst to obtain a condensed-ring aromatic pigment.

[0048] Further, the acid anhydride functionalized condensed ring aromatic compound derivative is selected from at least one of the following compounds:

[0049]

[0050] ...

Embodiment 1-6

[0085]

Embodiment 1~6

[0086] Embodiment 1~6 are all prepared according to the following method:

[0087] Mix 0.5kg of PMMA, (32g, 119mmol) compound (1-1), (25g, 231mmol) compound (1-2) and catalyst, extrude the reaction in a single-screw extruder, cool, dry and pelletize to obtain Crude color masterbatch containing compound (1-3).

[0088] Embodiments 1 to 6 are basically the same, except for the type and consumption of the catalyst, specifically as shown in Table 1:

[0089] Table 1

[0090]

[0091]

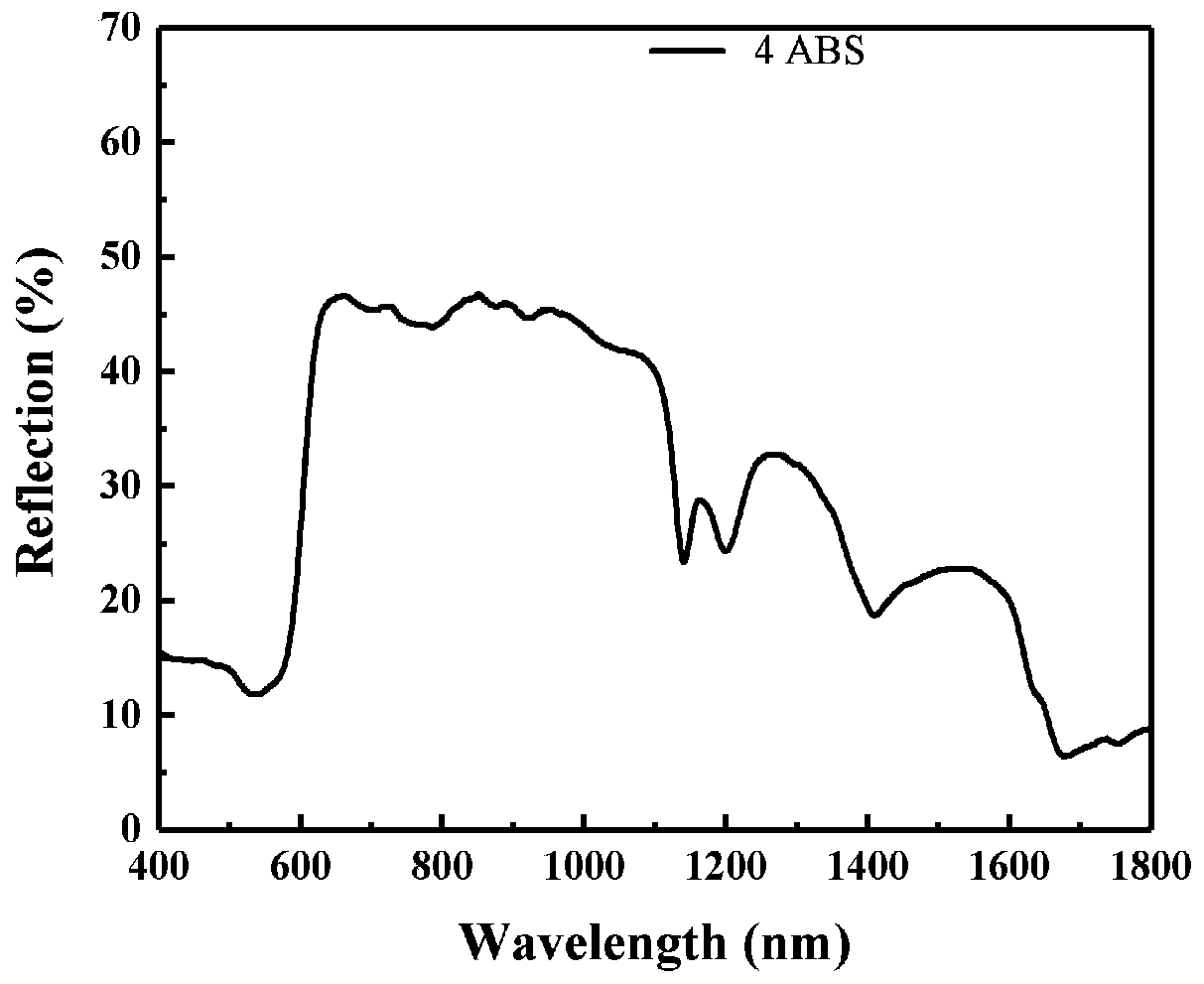

[0092] figure 1 The color masterbatch crude product prepared for embodiment 4 is mixed with ABS injection molding at a concentration of 1% to obtain the reflectance spectrum of a 1mm thick plastic sheet, which is obtained by figure 1 It can be seen that its absorption is mainly in the blue to orange light region, which is similar to the mixture of Pigment Orange 43 and Pigment Red 194.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com