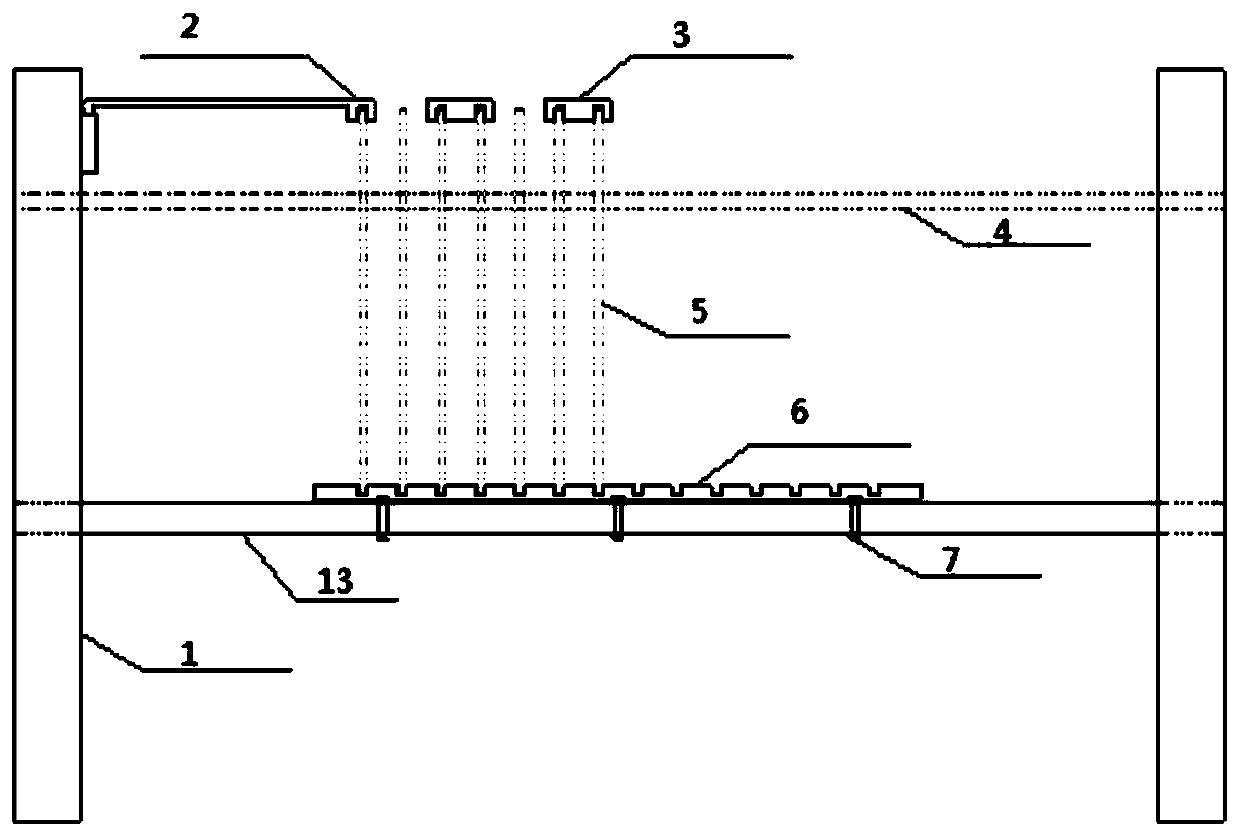

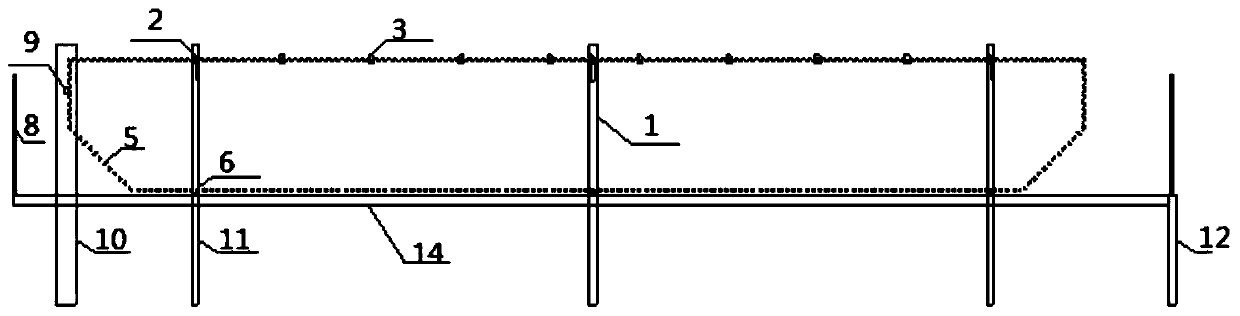

Capping beam steel reinforcement framework shaping binding bench

A steel frame and platform technology, which is applied to bridges, bridge parts, bridge construction, etc., can solve the problems of low precision of the finished cover beam frame, safety accidents of tilting and collapse, and large number of people required for operations, so as to increase the safety factor , work efficiency improvement, and the effect of reducing the construction scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] In 2018, during the construction of the TY04 contract section of Tianshuibao via Qingcheng to Yonghe Expressway undertaken by Gansu Road and Bridge Construction Group Co., Ltd., during the construction of the 435 cover beams on the whole line, the cover beam steel skeleton was processed by the bench method. The steel frame size and spacing of the cover beam are precisely controlled, and the pass rate of the concrete cover of the cover beam is high, which eliminates the error of manual measurement, saves labor and time, improves production efficiency, reduces safety risks, and effectively guarantees the durability of concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical spacing | aaaaa | aaaaa |

| Horizontal spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com