Coal mine coal gangue co-mining and partite-transport filling system and method

A technology for coal gangue and coal mine, which is applied in the field of coal mine filling and mining, can solve the problems of difficulty in separating coal gangue at the working face, and achieve the effects of low consumption, alleviation of washing pressure, and obvious economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described in detail below in conjunction with the description of the drawings and specific embodiments.

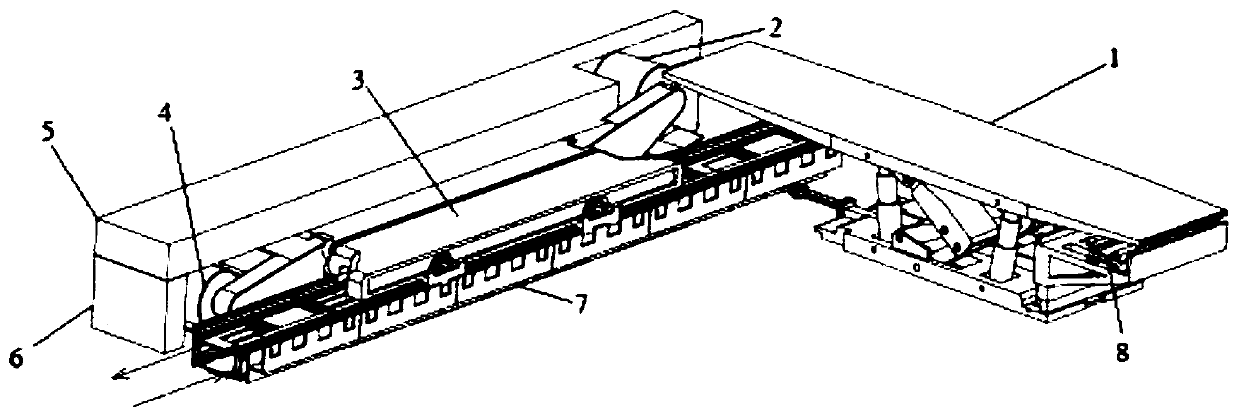

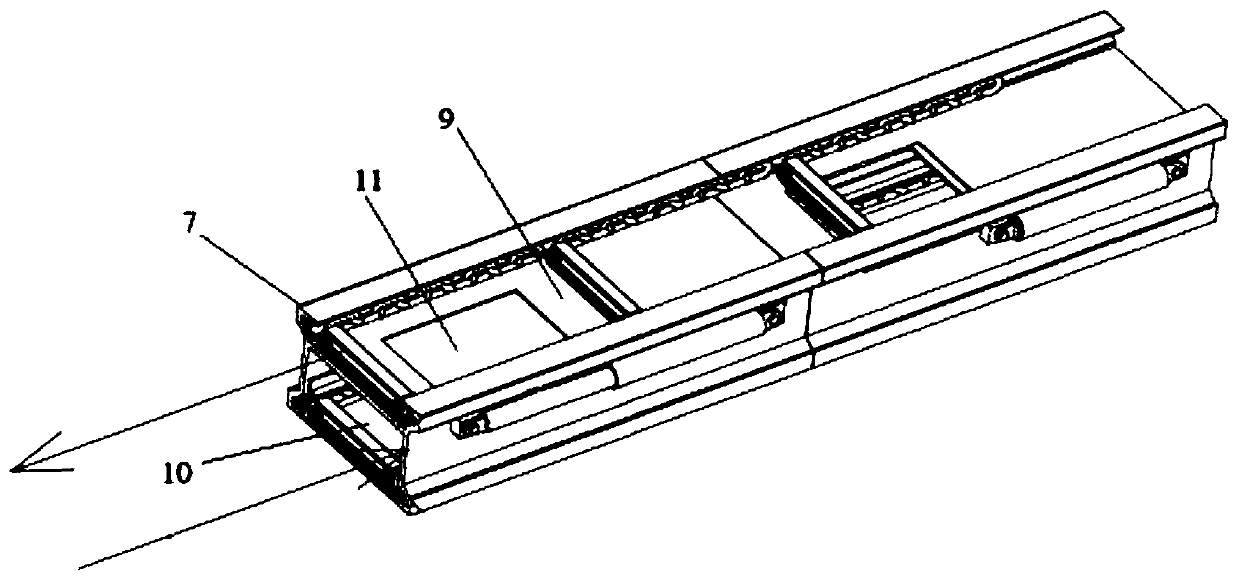

[0019] Such as figure 1 with figure 2 As shown, a coal mining and gangue filling system of the present invention includes a filling support 1, a filling scraper conveyor 8 is arranged at the rear end of the filling support 1, and a coal shearer 3 is arranged under the front end of the filling support 1 And the scraper conveyor 7 on the working surface, the scraper conveyor 7 on the working surface is provided with a groove bottom plate 10 and a plate 9 in the groove with a discharge port 11, and one end of the scraper conveyor 7 on the working surface is connected with the rubber transportation in the groove The tape is lapped / connected along the trough, and the other end is lapped / connected with the filling scraper conveyor 8 at the rear end of the filling bracket 1 .

[0020] Such as figure 1 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com