Lithium ion battery negative electrode material recycling method

A technology for lithium-ion batteries and negative electrode materials, which is applied in the field of recycling of waste lithium-ion battery negative electrode materials, can solve the problems of reducing the recycling value of original graphite, expensive process flow, environmental impact, etc., and achieve high quality, recycling volume, and cost Low cost and high recovery rate

Active Publication Date: 2020-01-14

CENT SOUTH UNIV

View PDF8 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, these methods involve acids and other solvents, and the process becomes expensive and has an impact on the environment. At the same time, the recycled graphite is leached

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

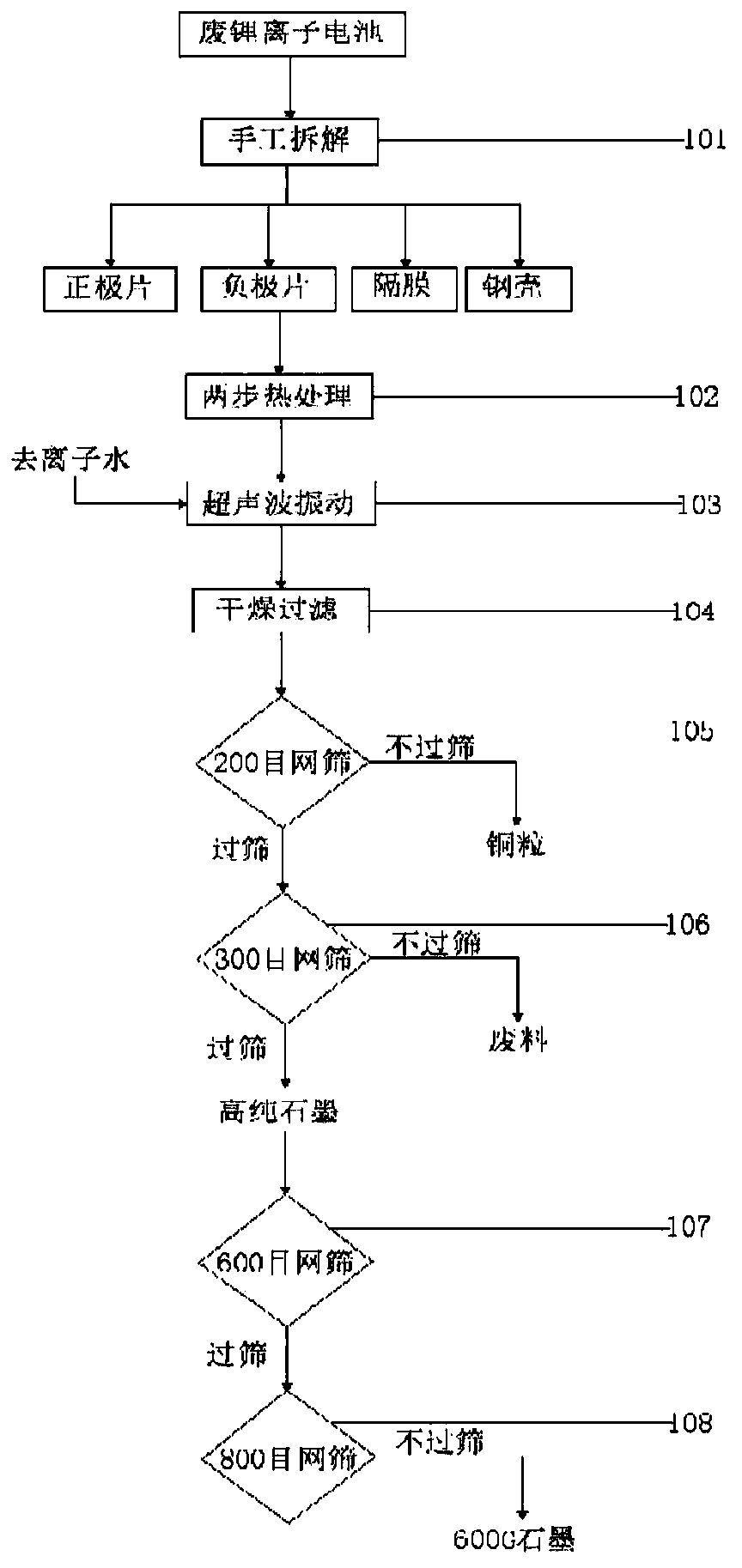

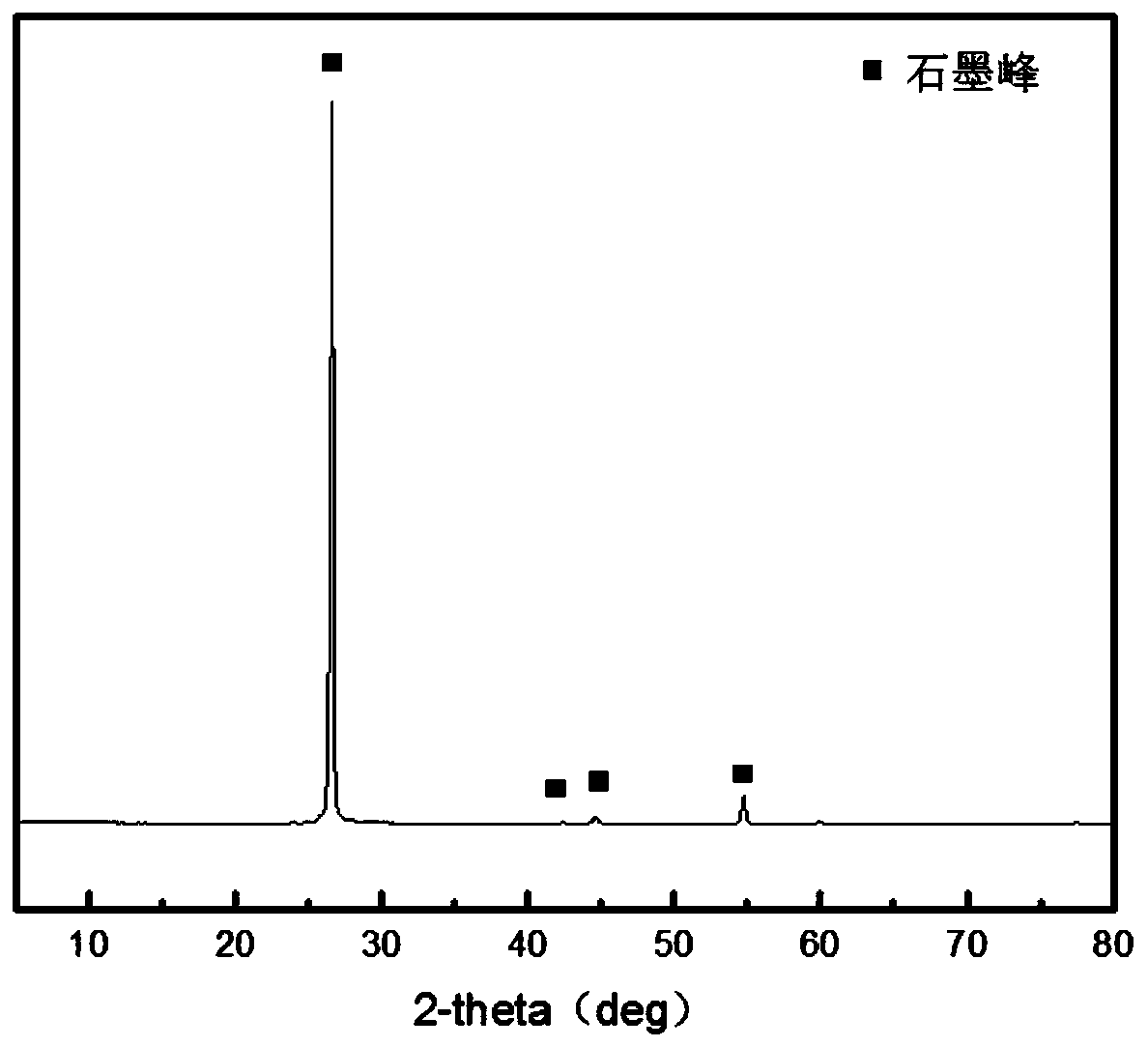

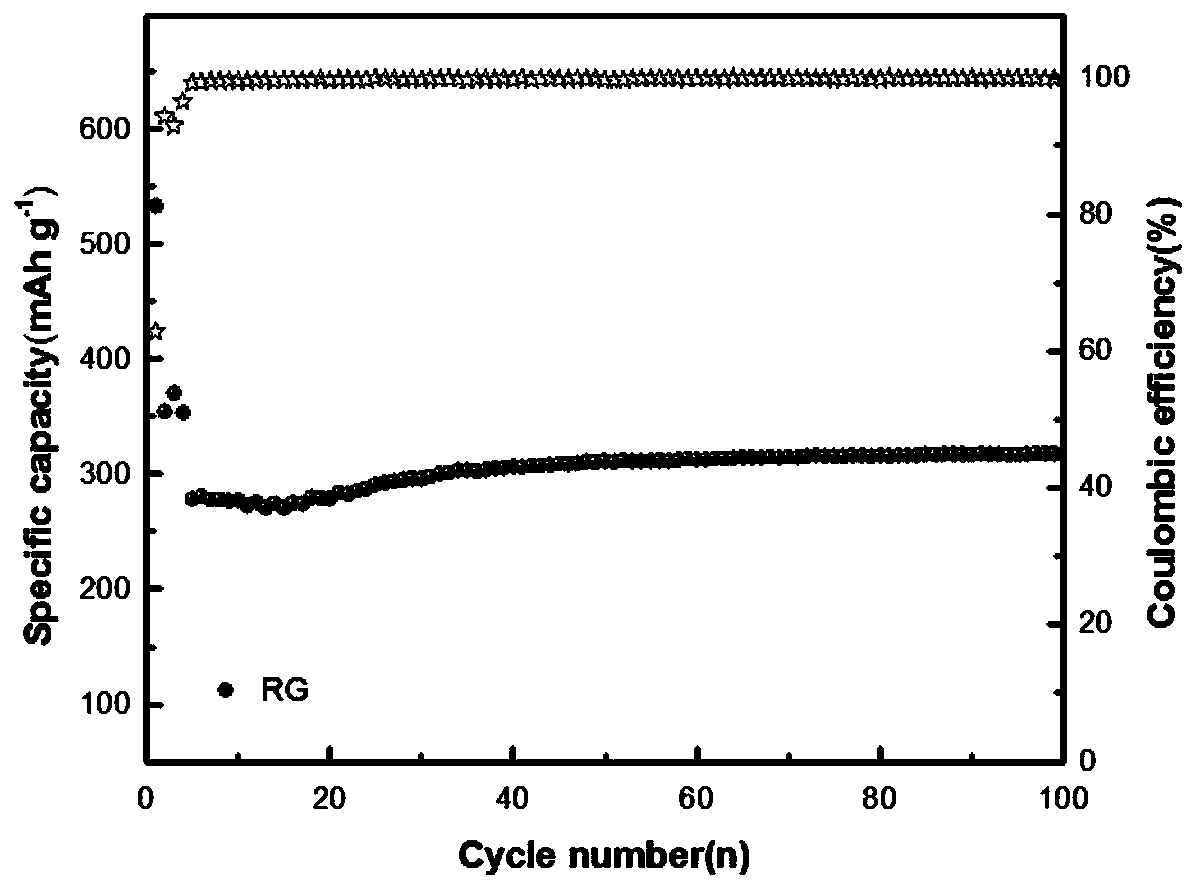

The invention discloses a lithium ion battery negative electrode material recycling method which comprises the following steps: disassembling a lithium ion battery, and separating out a negative electrode material; cutting the negative electrode material into fragments, and putting the fragments into a tubular furnace to be heated twice to obtain powder; mixing the powder with deionized water, performing ultrasonic vibration treatment, and filtering and drying the solution subjected to vibration treatment to obtain residual powder; and screening the remaining powder through screens with different meshes, to obtain copper particles and high-purity graphite. The high-purity graphite can be subjected to fine screening subsequently, and graphite with better electrochemical performance is obtained. The lithium ion battery negative electrode material recycling method is simple to operate, low in cost, high in recovery rate and capable of being used for industrial production, and recovery ofcopper and high-purity graphite in negative electrodes is realized by performing two-step heat treatment, ultrasonic vibration, filtration and screening on waste lithium ion battery negative electrodes.

Description

technical field [0001] The invention relates to the field of material recovery, in particular to a method for recovery and reuse of anode materials of waste lithium ion batteries. Background technique [0002] With the development of the electric vehicle industry, the demand for batteries has grown rapidly in recent years. Traditional batteries such as lithium batteries, lead-acid batteries, and nickel-cadmium batteries are gradually being replaced by lithium-ion batteries due to their high energy density, no memory effect, and low self-discharge characteristics. However, the life expectancy of lithium-ion batteries is usually between 3 and 10 years. Therefore, there is an urgent need for an efficient and economical recycling technology for spent lithium-ion batteries. The recycling of spent lithium-ion batteries not only has good economic benefits, but also significantly reduces the impact on the environment. [0003] Li-ion batteries typically contain 5-15% cobalt, 5-10...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M10/54C01B32/20C01B32/215C22B7/00C22B15/00

CPCH01M10/54C22B7/001C22B15/0056C01B32/215C01B32/20Y02W30/84Y02P10/20

Inventor 杨越易晨星伍喜庆孙伟易龙生

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com