Electronic skin having classified voltage crest structure and preparation method of electronic skin

A technology of electronic skin and conductivity, which is applied in the field of sensors, can solve problems such as limited application prospects and low sensitivity, and achieve the effects of good repeatability, high sensitivity, and fast response recovery ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

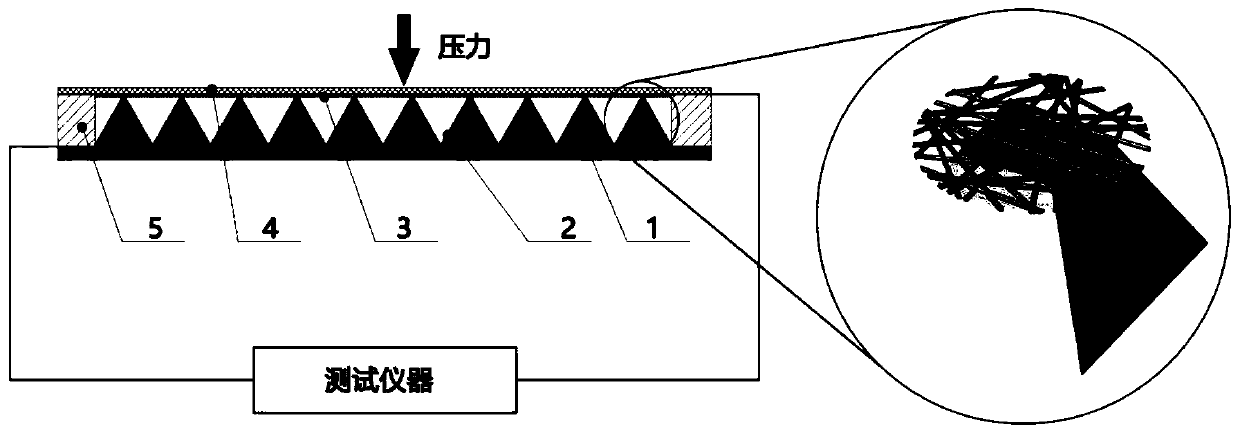

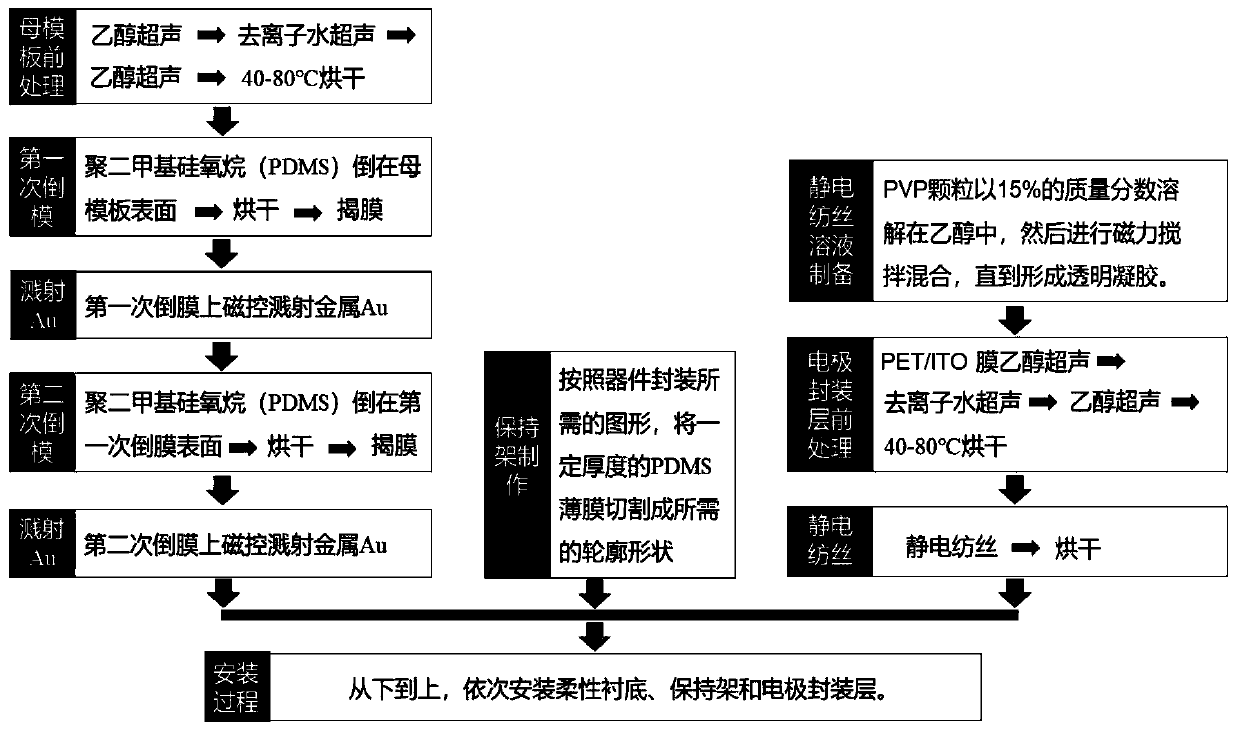

[0054] The present invention also provides a method for preparing an electronic skin with a hierarchical pressure peak structure, which includes the following steps:

[0055] S1 prepares a flexible substrate sputtered with a pressure sensitive layer on the surface:

[0056] First prepare a master template with a raised structure on the surface, wash and dry, then use the master template to prepare an inverted mold and prepare an isolation layer on the surface of the inverted mold, and then use the inverted mold with an isolation layer on the surface to prepare a flexible substrate, and finally Sputter a pressure sensitive layer on the surface of the substrate to obtain a flexible substrate with a pressure sensitive layer sputtered on the surface, specifically:

[0057] S11 master template production: the metal block is made into a master template with an array of raised structures on the surface through a CNC grinder;

[0058] Pre-treatment of the S12 master template: The master templ...

Embodiment 1

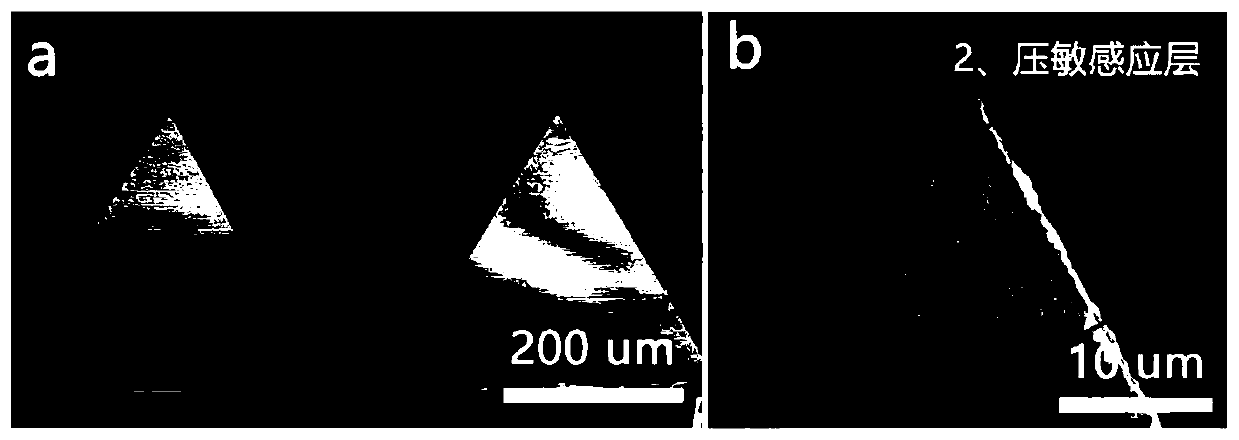

[0081] This embodiment is the preparation of an electronic skin with a hierarchical pressure peak structure based on magnetron sputtering gold, PVP nanowire nets, and a micro-pyramid array. The specific preparation is carried out by the following steps:

[0082] 1) The metal block is made into a master template with a pyramid array on the surface through a CNC grinder;

[0083] 2) After sonicating the finished master template with ethanol for 10 minutes, sonicating with deionized water for 10 minutes, then sonicating with ethanol for 10 minutes, drying at 50°C;

[0084] 3) Pour the pre-mixed polydimethylsiloxane (PDMS) on the surface of the master template, after drying, peel off to obtain the first inverted mold;

[0085] 4) Sputtering a gold layer on the surface of the first inverted mold;

[0086] 5) Pour the premixed polydimethylsiloxane (PDMS) on the surface of the first inverted mold, and after drying, peel off to obtain a flexible substrate with a micro-pyramid array, the micro-p...

Embodiment 2

[0094] This implementation is the preparation of an electronic skin with a hierarchical pressure peak structure based on graphene, PVP nanowire nets and micro-hemisphere arrays, and the specific preparation is carried out by the following steps:

[0095] 1) Using photolithography to prepare a master template with micro-hemispherical pits on a silicon wafer;

[0096] 2) After sonicating the finished master template with ethanol for 30 minutes, sonicating with deionized water for 15 minutes, then sonicating with ethanol for 20 minutes, drying at 40°C;

[0097] 3) Pour the pre-mixed polydimethylsiloxane (PDMS) on the surface of the master template, after drying, peel off to obtain the first inverted mold;

[0098] 4) Layered self-assembled graphene on the surface of the first inverted mold to form an isolation layer;

[0099] 5) Pour the premixed polydimethylsiloxane (PDMS) on the surface of the first inverted mold, and after drying, peel off to obtain a flexible substrate with a micro-hem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com