Evaporator and steam-water separating device thereof

A steam-water separation device and technology of separation device, which are applied to evaporator accessories, evaporation, separation methods, etc., can solve the utility discount of steam-water separation device, the failure of liquid level control system, and the inability to prevent evaporative liquid from entering the lower heat exchanger or vacuum pump. and other problems, to achieve the effect of being suitable for promotion and use, preventing material running, and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

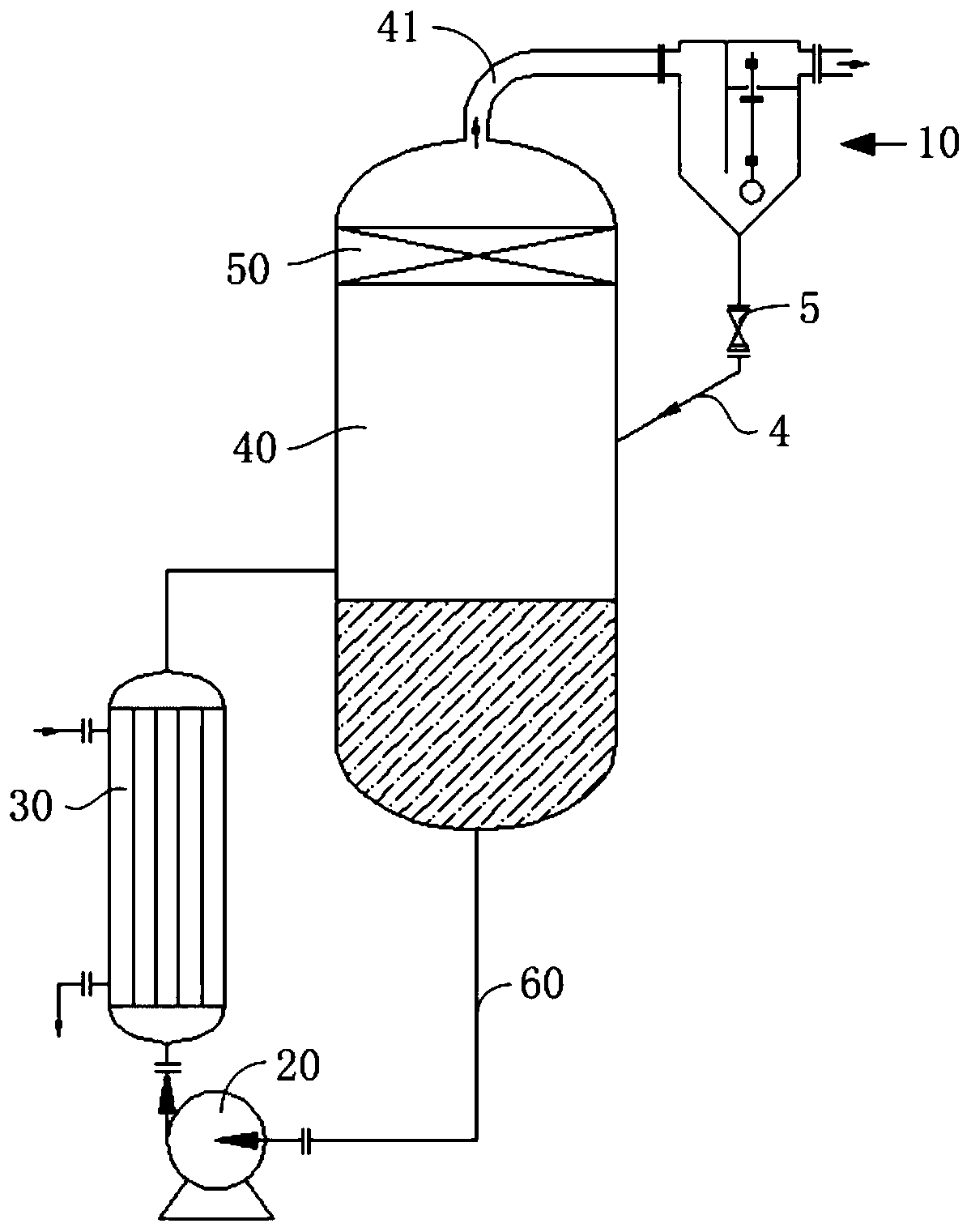

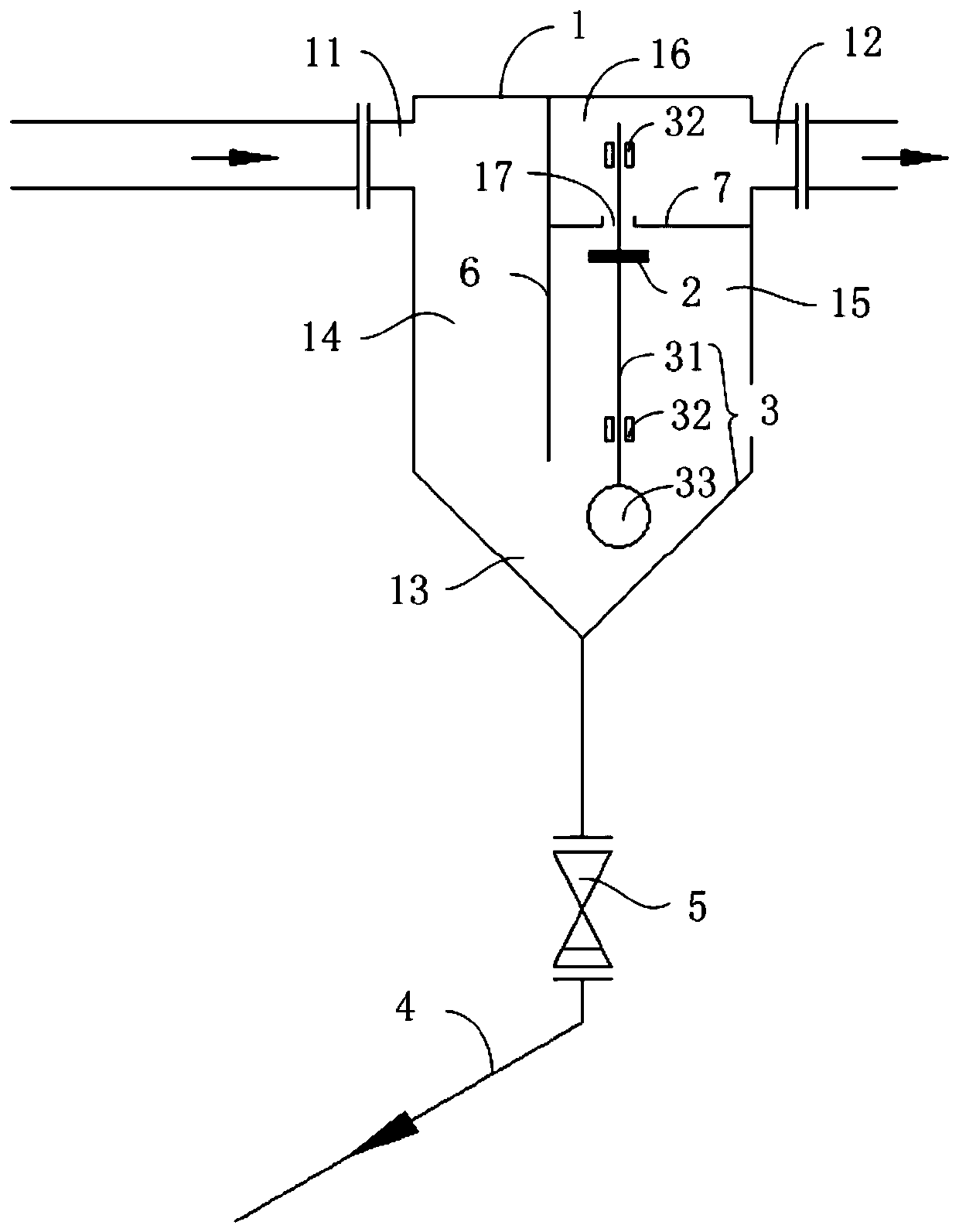

[0025] Please refer to Figure 1-2 , figure 1 is a schematic structural view of the evaporator provided by the embodiment of the present invention; figure 2 yes figure 1 Schematic diagram of the structure of the steam-water separation device.

[0026] The embodiment of the present invention provides an evaporator and its steam-water separation device 10, wherein, as figure 1 As shown, the evaporator includes a circulation pump 20, a heat exchanger 30, an evaporation separation device 40 and a steam-water separation device 10, and the heat exchanger 30 and the evaporation separation device 40 are connected by a circulation pipeline 60 to form a circulating water circuit, and the circulation pump 20 is connected to the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap