Control method and system for adjusting blowing of injection valve in real time based on bad points and sizes

A technology of real-time adjustment and control method, applied in the field of color sorters, can solve the problems of blowing the material too far during the blowing time, and the material cannot fall into the waste outlet, etc., and achieves the effect of saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

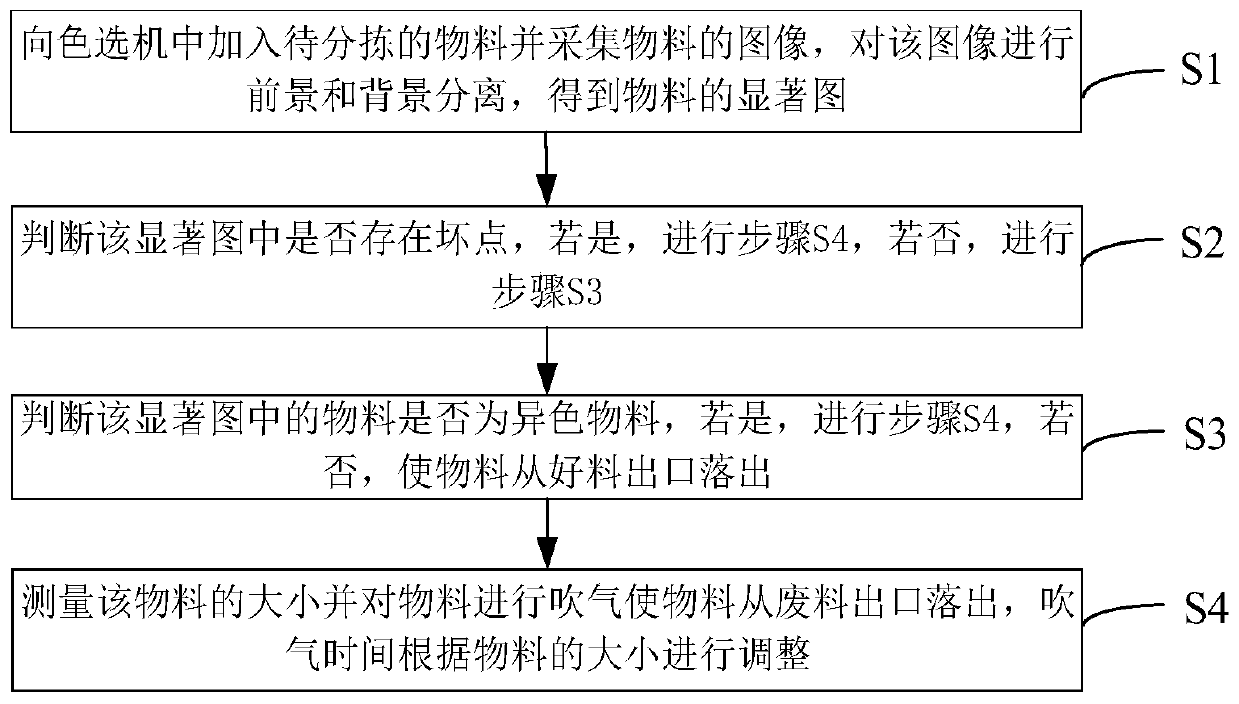

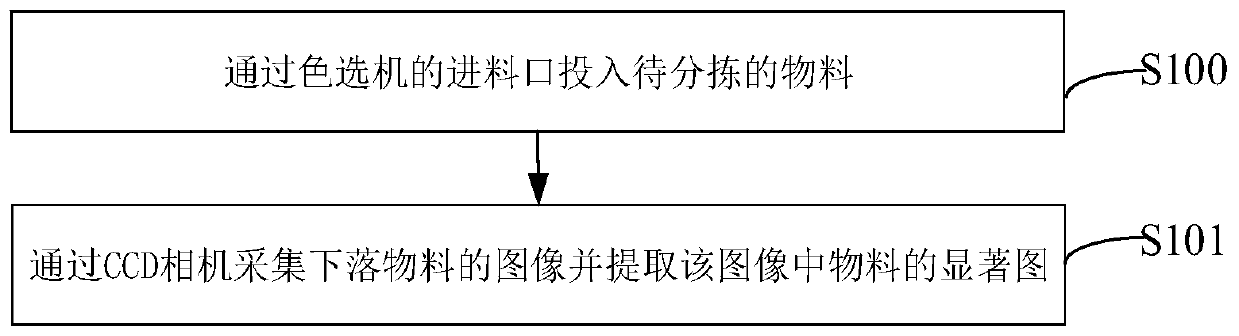

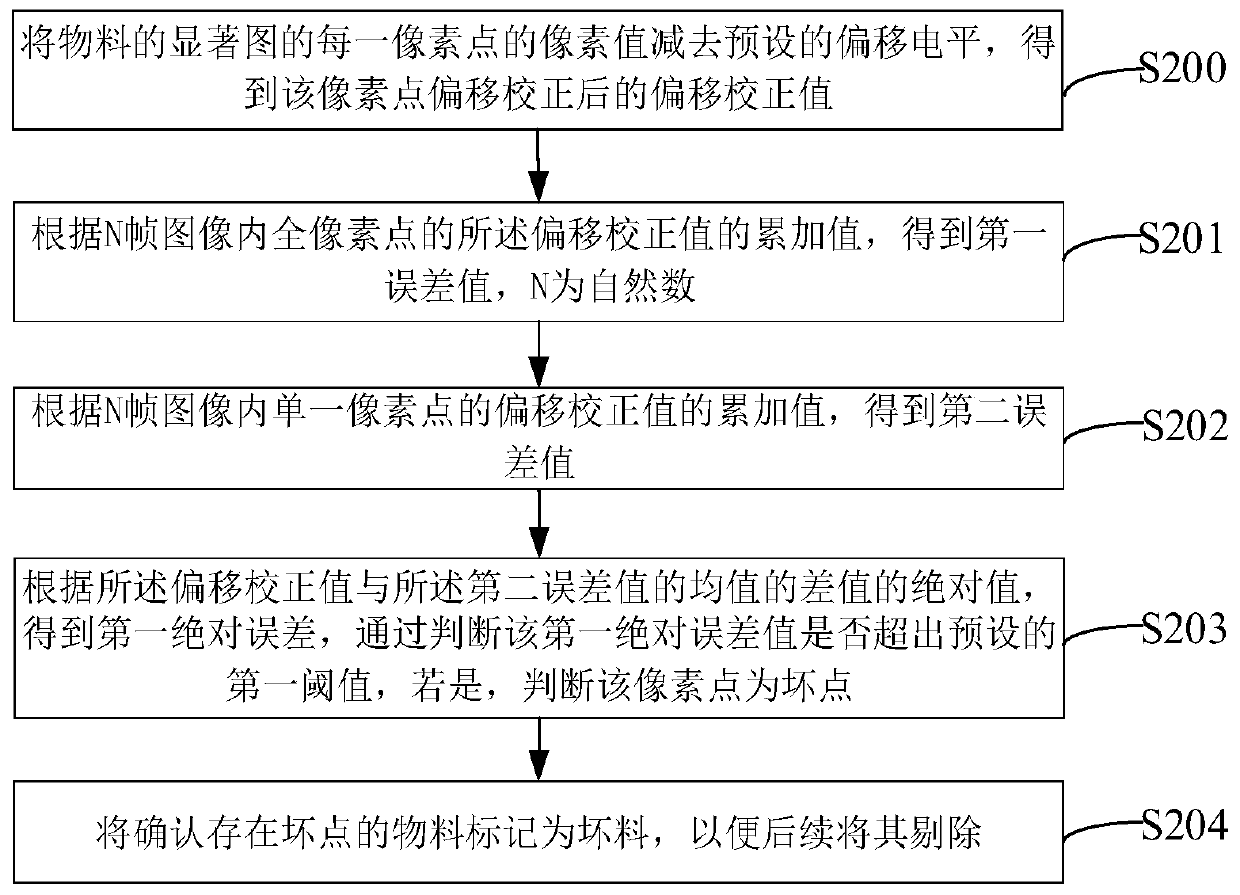

[0023] see figure 1 As shown, a control method for real-time adjustment of nozzle blowing air based on dead pixels and sizes, including: S1, adding materials to be sorted into the color sorter and collecting images of the materials, and separating the foreground and background of the images, Obtain the saliency map of the material; S2, judge whether there is a bad point in the saliency map, if so, go to step S4, if not, go to step S3; S3, judge whether the material in the saliency map is a heterochromatic material, if so, go to step S4, if not, let the material fall out from the good material outlet; S4, measure the size of the material and blow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com