A double-sided switching vacuum adsorption plate

A vacuum adsorption, double-sided technology, applied in the direction of large fixed members, clamping, support, etc., can solve the problems of being easily crushed, narrow use range, uneven vacuum adsorption force, etc., to improve the adsorption effect and ensure quality control , to avoid the effect of workpiece damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

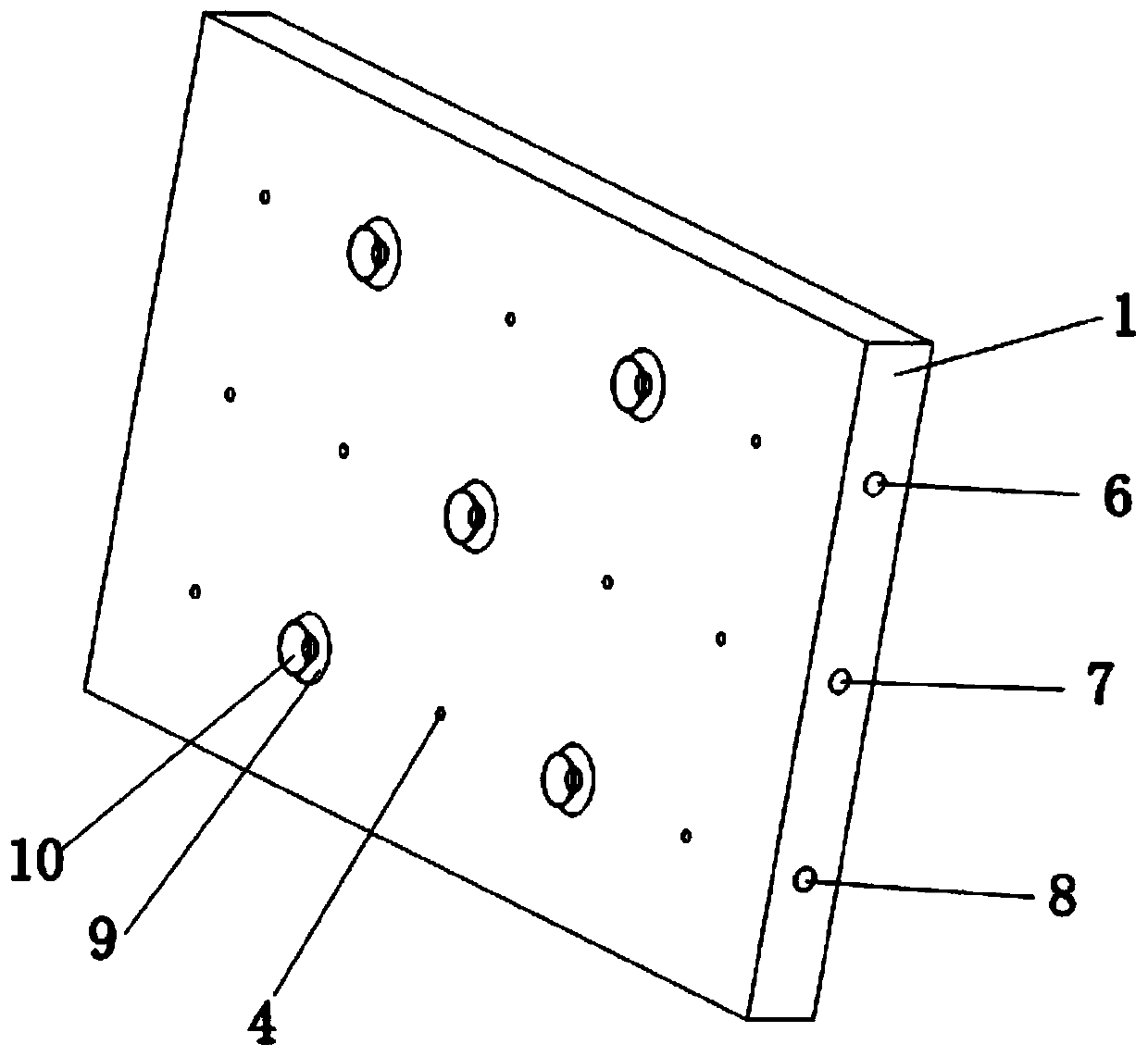

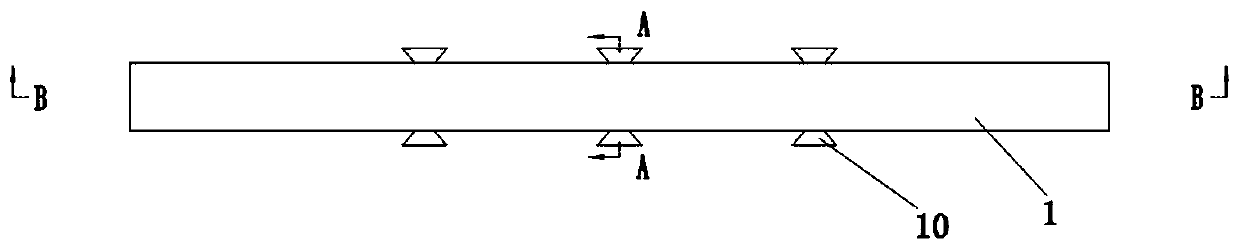

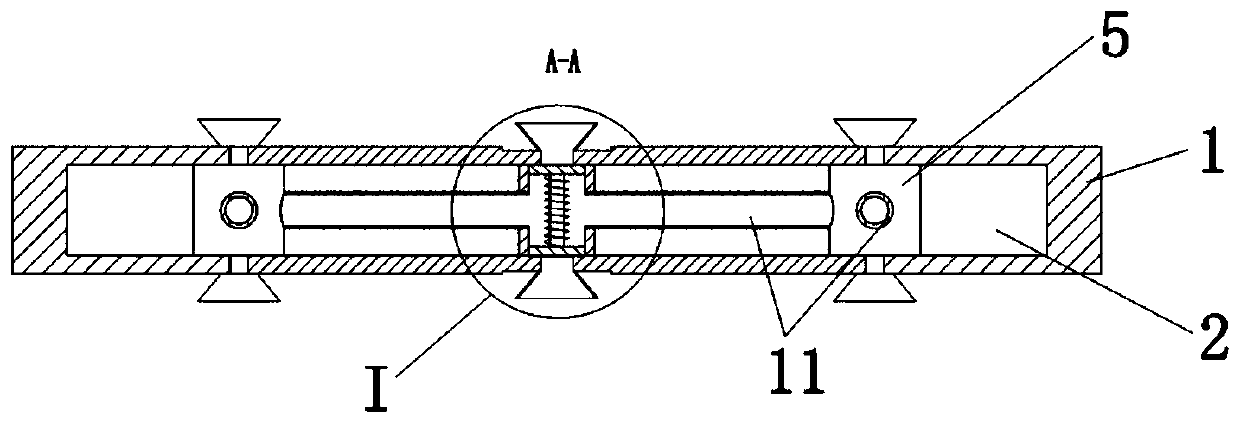

[0028] Such as Figure 1-5 A double-sided switching vacuum adsorption plate is shown, which includes a plate body 1 made of metal. The plate body 1 includes a first contact plate 101 and a second contact plate 102 opposite to each other. The plate body 1 is on the first contact plate 101. A chamber 2 is provided between the first contact plate 101 and the second contact plate 102. There are five groups of large adsorption holes 3 in the center of the plate body 1 and several evenly distributed small adsorption holes on the first contact plate 101 and the second contact plate 102. 4. An adsorption switching device 5 is fixed inside the chamber 2 , and a main suction port 6 , a secondary suction port 7 and an air intake port 8 are arranged on one side of the plate body 1 . Wherein, the auxiliary air inlet 7 communicates with the chamber 2, and the adsorption switching device 5 includes a sealing sleeve 501 and a telescopic rod 502 concentrically arranged with the large adsorptio...

Embodiment 2

[0030] When it is necessary to exchange and transfer workpieces on two opposite workbenches, for example, glass in a glass factory is placed vertically, and when glass of different quality needs to be replaced, the workpiece can be grasped by approaching one of the workbenches through the first contact plate 101 Picking, and then grabbing the workpiece close to another workbench through the second contact plate 102. At this time, it is not necessary to turn over the vacuum adsorption plate to realize double-sided switching vacuum adsorption grabbing, which greatly saves work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com