Pipeline section with cooling and leakage detecting functions and applied to low-vacuum magnetic levitation system

A technology of vacuum pipes and cooling pipes, applied in tunnel systems, roads, tracks, etc., can solve the problems of high construction difficulty, high construction cost, large installation space, etc., achieve broad application prospects and industrialization prospects, and achieve direct radiation cooling. , The effect of reducing the difficulty of leak detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

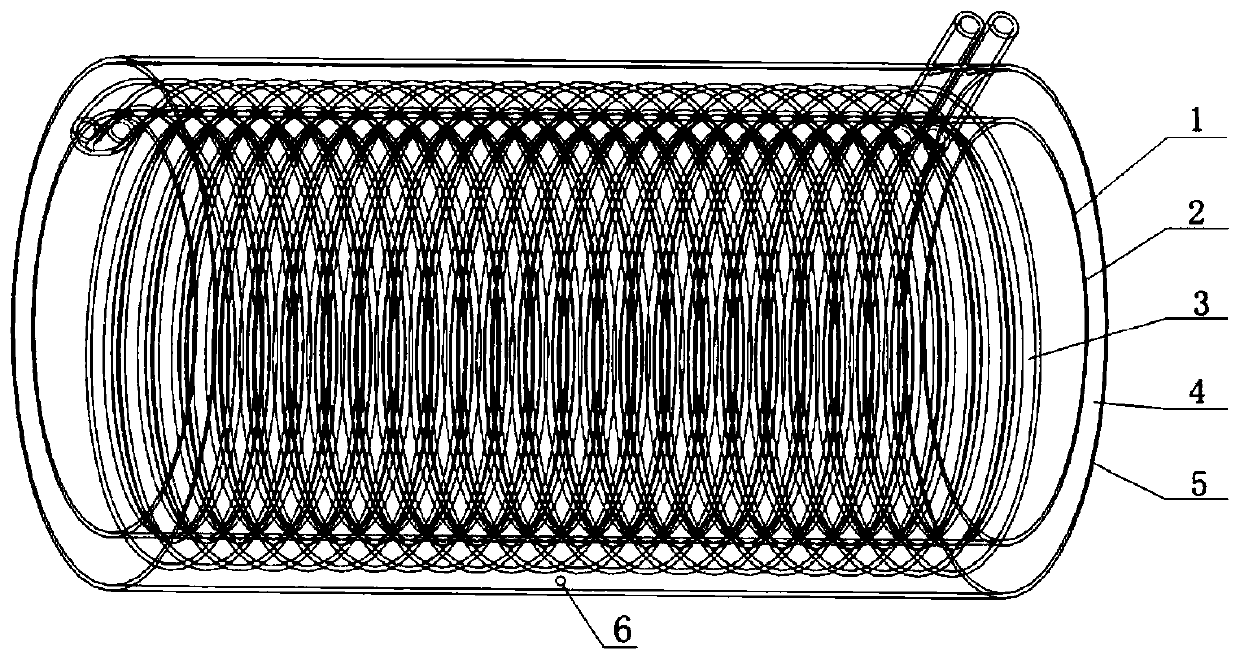

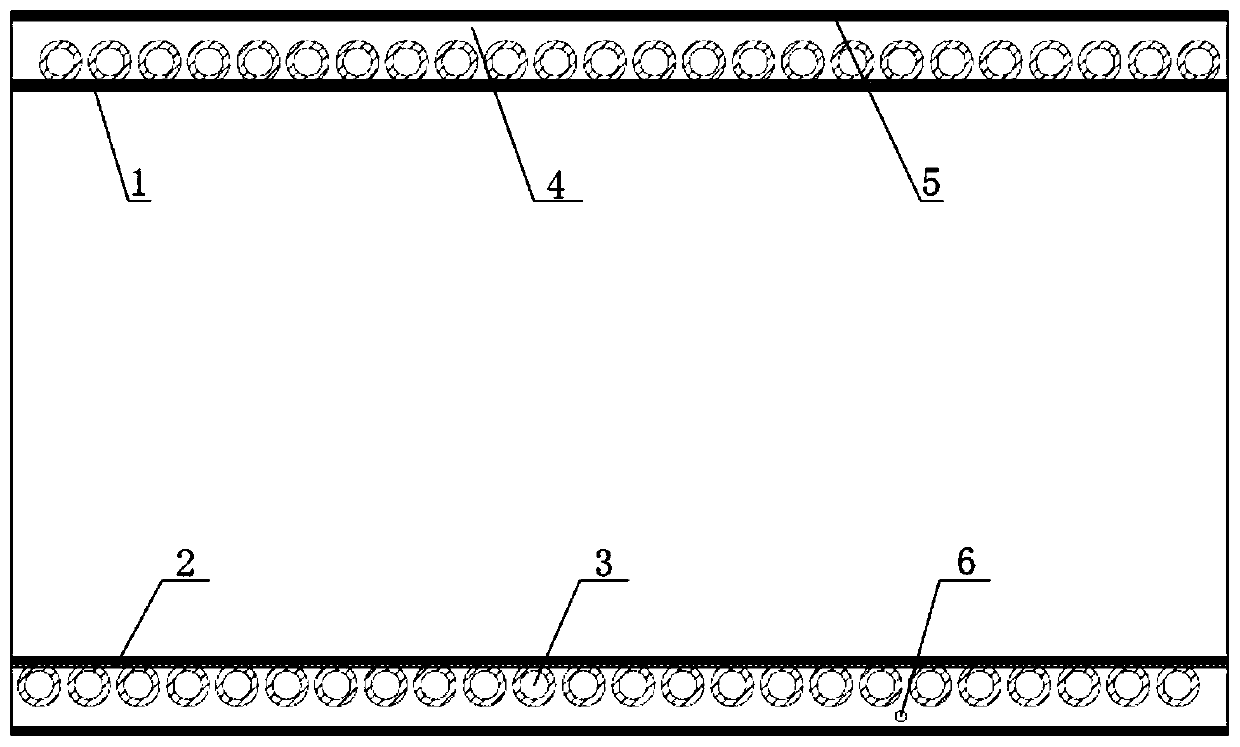

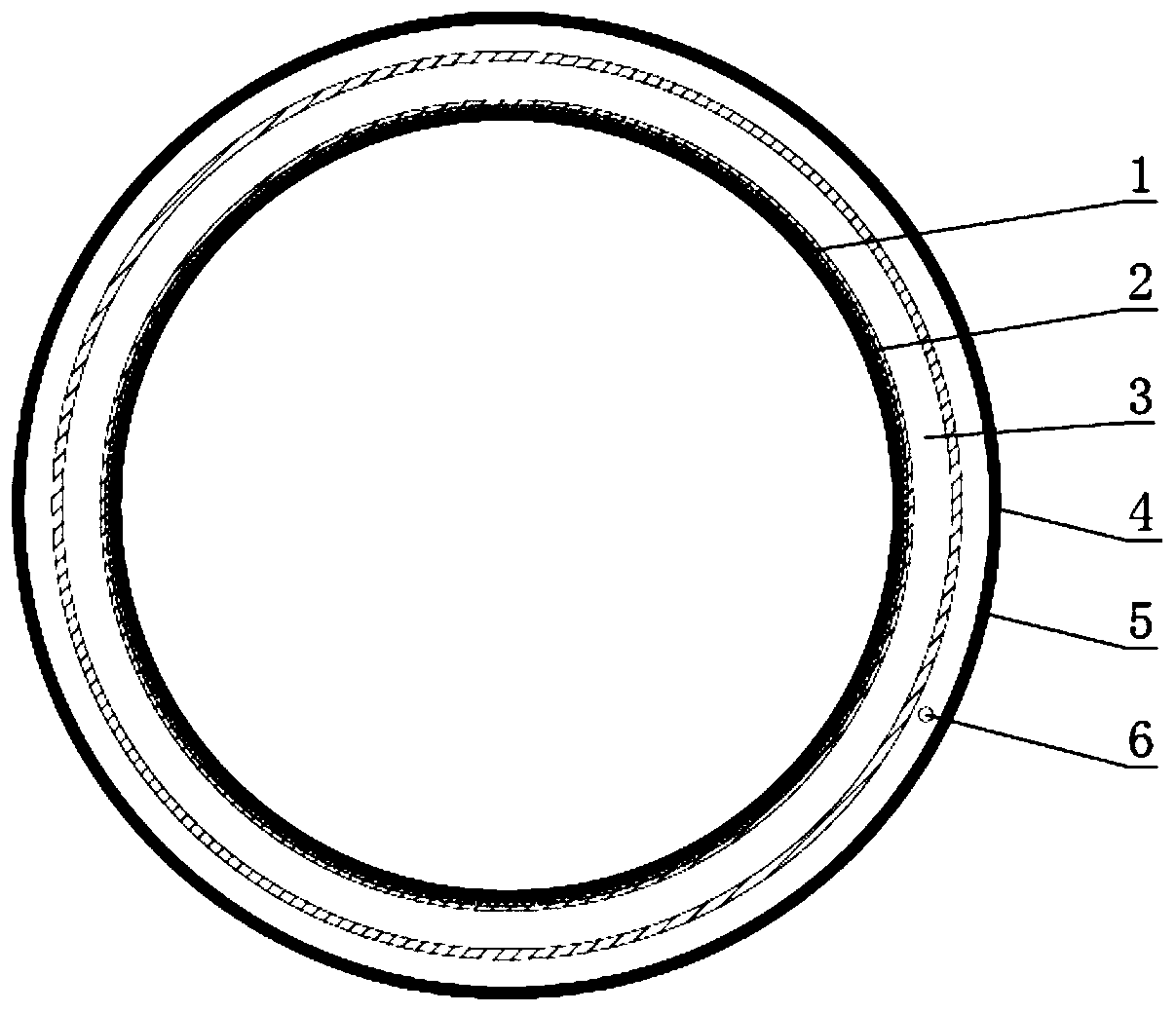

[0016] Such as Figure 1 to Figure 3 As shown, a pipeline section with cooling and leak detection functions applied to a low vacuum magnetic levitation system of the present invention includes a vacuum pipeline laid in the magnetic levitation system, and the vacuum pipeline is composed of multiple vacuum pipeline sections; the vacuum pipeline It is a double-layer pipeline, including the inner wall 1 of the vacuum pipeline and the outer wall 5 of the vacuum pipeline; a cooling pipeline 3 and an intermediate layer 4 are laid between the inner wall 1 of the vacuum pipeline and the outer wall 5 of the vacuum pipeline, and the cooling pipeline 3 is attached to the inner wall 1 of the vacuum pipeline. The cooling pipe 3 removes the heat in the pipe through cold water; the silicone grease heat-conducting layer 2 is coated between the cooling pipe 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com