Method for constructing sectional cooling system in blast furnace

A technology of cooling system and construction method, which is applied to blast furnaces, cooling devices, blast furnace details, etc., can solve the problems of unstable slag skin, affecting the stability of furnace conditions, and damage to cooling equipment, so as to achieve the reduction of working environment and labor intensity. Improvement of efficiency and safety, reduction of average water temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

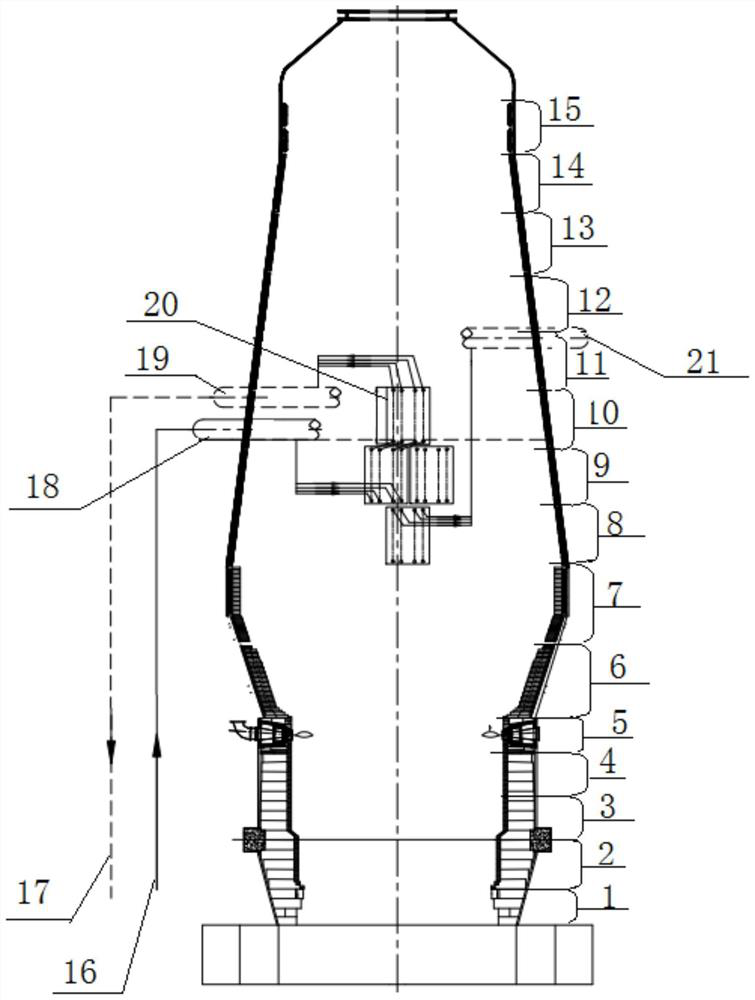

Image

Examples

Embodiment 1

[0063] The large blast furnace of the ironworks was put into operation on October 6, 2010. During the mid-term maintenance in 2016, the cooling wall of the ninth section of the furnace lower part was replaced. In 2019, as the smelting intensity of the blast furnace gradually increased, the number of damages to the cooling equipment in the 9th-10th section of the lower part of the shaft increased. On the one hand, water leakage will consume the heat of the blast furnace due to the decomposition and absorption of carbon water reaction. On the other hand, the cooling water entering the furnace will also cause local thickening of the furnace wall, and the slag skin is unstable and prone to frequent drop. A large amount of slag skin falls into the furnace hearth It will cause the temperature of the blast furnace to cool down sharply, leading to furnace cooling accidents. In April and May 2019, frequent slag peelings made it difficult to maintain stable production of the blast furnac...

Embodiment 2

[0086] The difference between this embodiment and the previous embodiment is that the subsection cooling system in the middle of the blast furnace also includes a water leakage control module; the water leakage control module performs the following operations:

[0087] T1. Obtain the surge state and water leakage of each cooling wall in the independent cooling system;

[0088] T2. Judgment of water leakage according to the water surge state and water leakage of each cooling wall, and mark the leaking cooling wall;

[0089]T3. Classify the marked leaky cooling walls to obtain A-level leaky cooling walls, B-level leaking cooling walls and C-level leaking cooling walls;

[0090] T4. Issue management and control instructions for each leaky stave according to the management and control strategies for Class A leaky staves, Class B leaky staves and Class C leaky staves.

[0091] The A-level leaky cooling wall includes a leaking cooling wall with a water leakage ≥ 50kg / h;

[0092] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com