Vacuum seal garbage can with vegetable washing sink arranged at upper part

A technology of vacuum sealing and vegetable washing pool, which is applied in the direction of garbage cans, garbage cleaning, garbage collection, etc., which can solve the problems of outward diffusion and odor leakage, so as to protect the air environment, reduce the release of garbage odor, and improve airtightness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

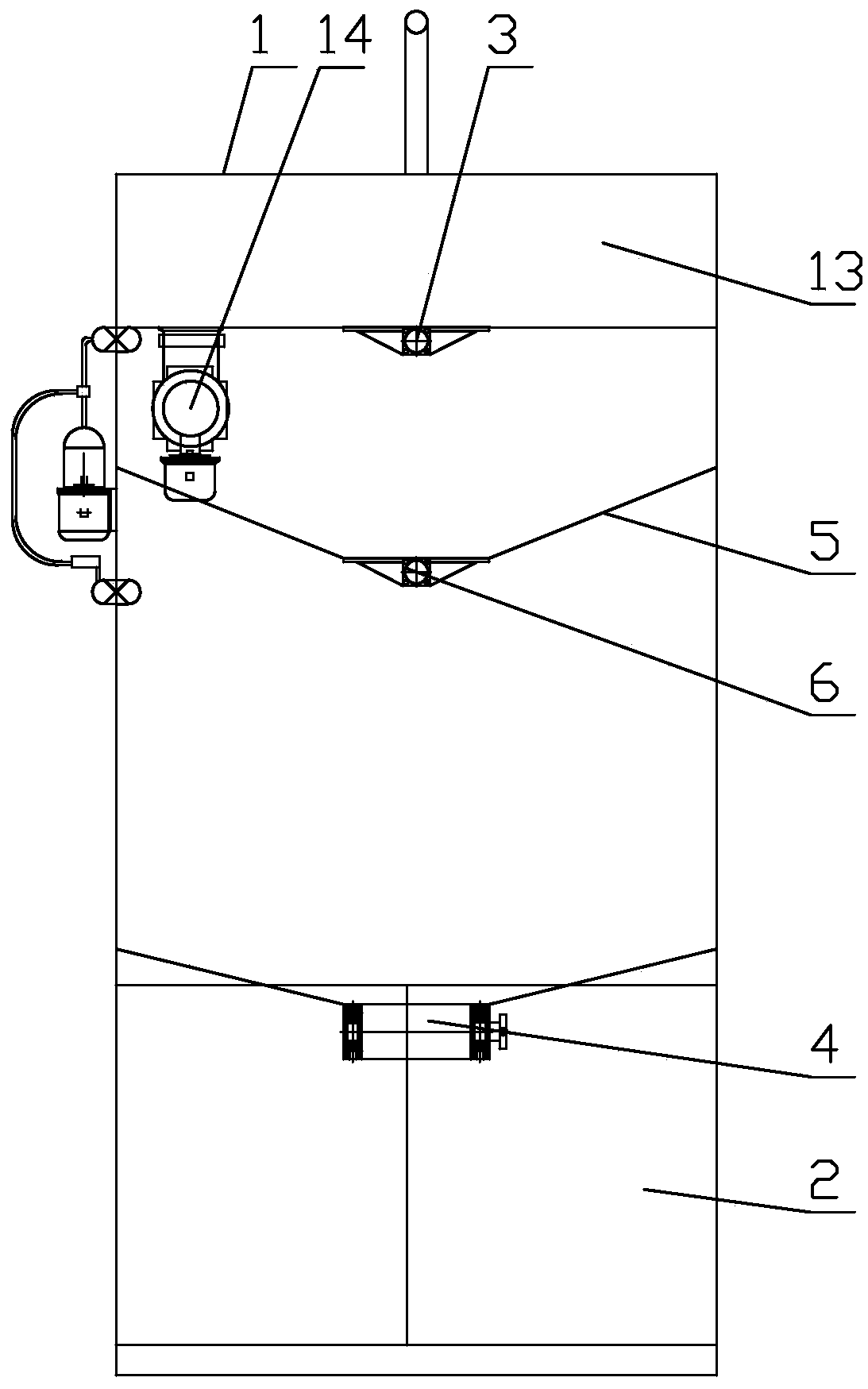

[0056] Such as figure 1 As shown, a type of vacuum-sealed garbage bin with a vegetable washing pool on top includes a box body 1,

[0057] The lower part of the box body 1 is provided with a sealed door 2;

[0058] The top of the casing 1 is provided with a vegetable washing pool 13, and the bottom of the vegetable washing pool 13 is provided with a drainpipe 14, a drop-in port and a throwing door 3; A water tap is provided, and the water tap can be opened to directly wash vegetables in the vegetable washing pool 13, the sewage is discharged from the drain pipe 14, and the garbage enters the box from the input port and the input door 3;

[0059] A discharge port and a discharge door 4 are provided at positions corresponding to the sealed door 2 in the box body 1; a discharge bucket can be set in the box body 1, and the discharge port and the discharge door are arranged at the bottom of the discharge bucket;

[0060] Several isolation buckets 5 are arranged in the box body 1 ...

Embodiment 2

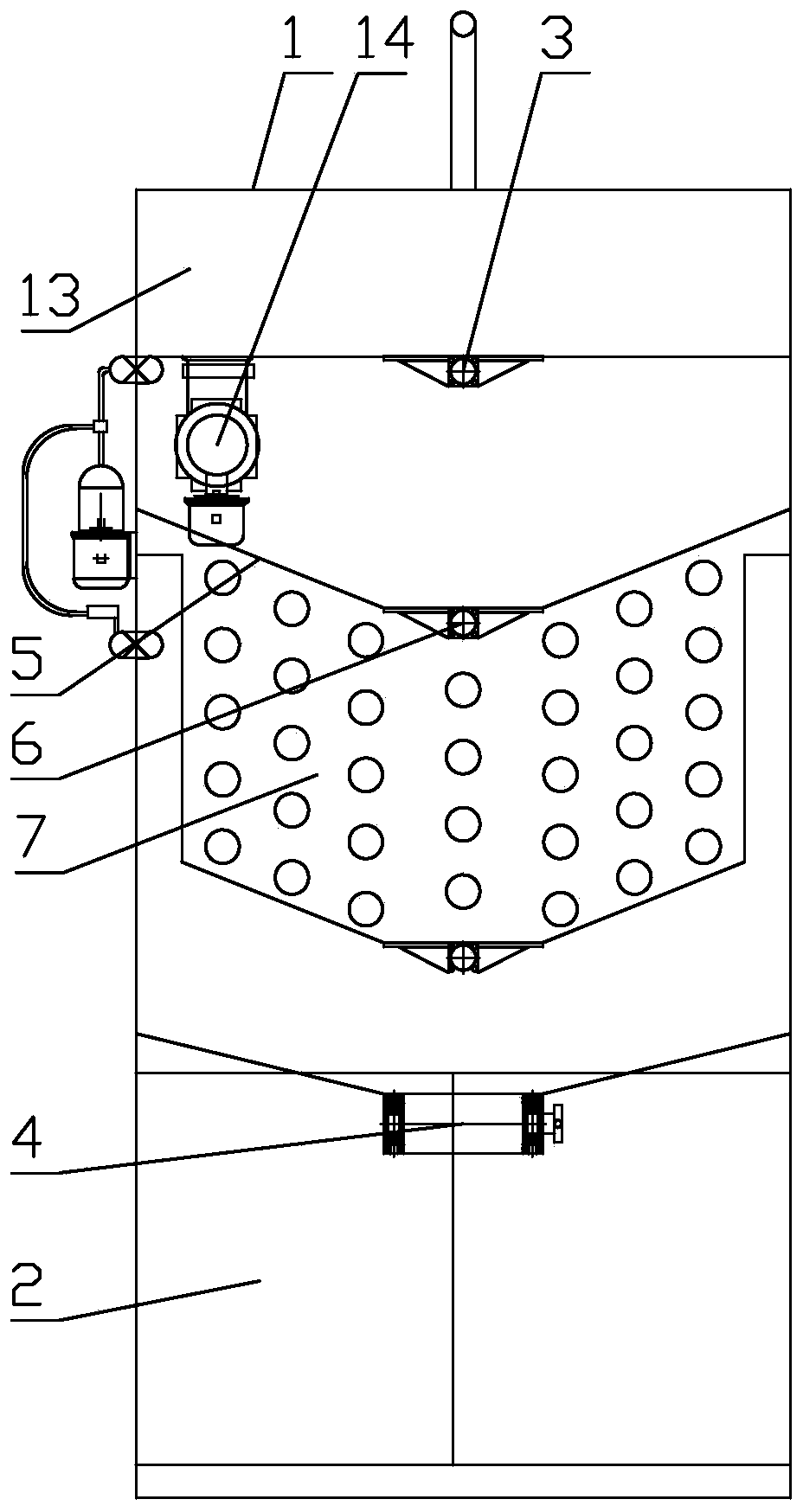

[0068] Such as figure 2 As shown, the difference between this embodiment and embodiment 1 is:

[0069] The box body 1 is provided with a solid-liquid separation box 7 for separating solid garbage and liquid garbage. The solid-liquid separation box 7 is arranged in the cavity of the lowest floor, and the side wall of the solid-liquid separation box 7 is provided with some liquid seepage holes, and the bottom of the solid-liquid separation box 7 is provided with a separation door, and the structure of the separation door can refer to that of the delivery door. structure. The liquid garbage will seep downward from the liquid seepage hole, and the solid garbage will be left in the solid-liquid separation box 7. After opening the discharge door 4, the liquid garbage can be put into the bag first, and then the separation door can be opened to pack the solid garbage into the bag .

Embodiment 3

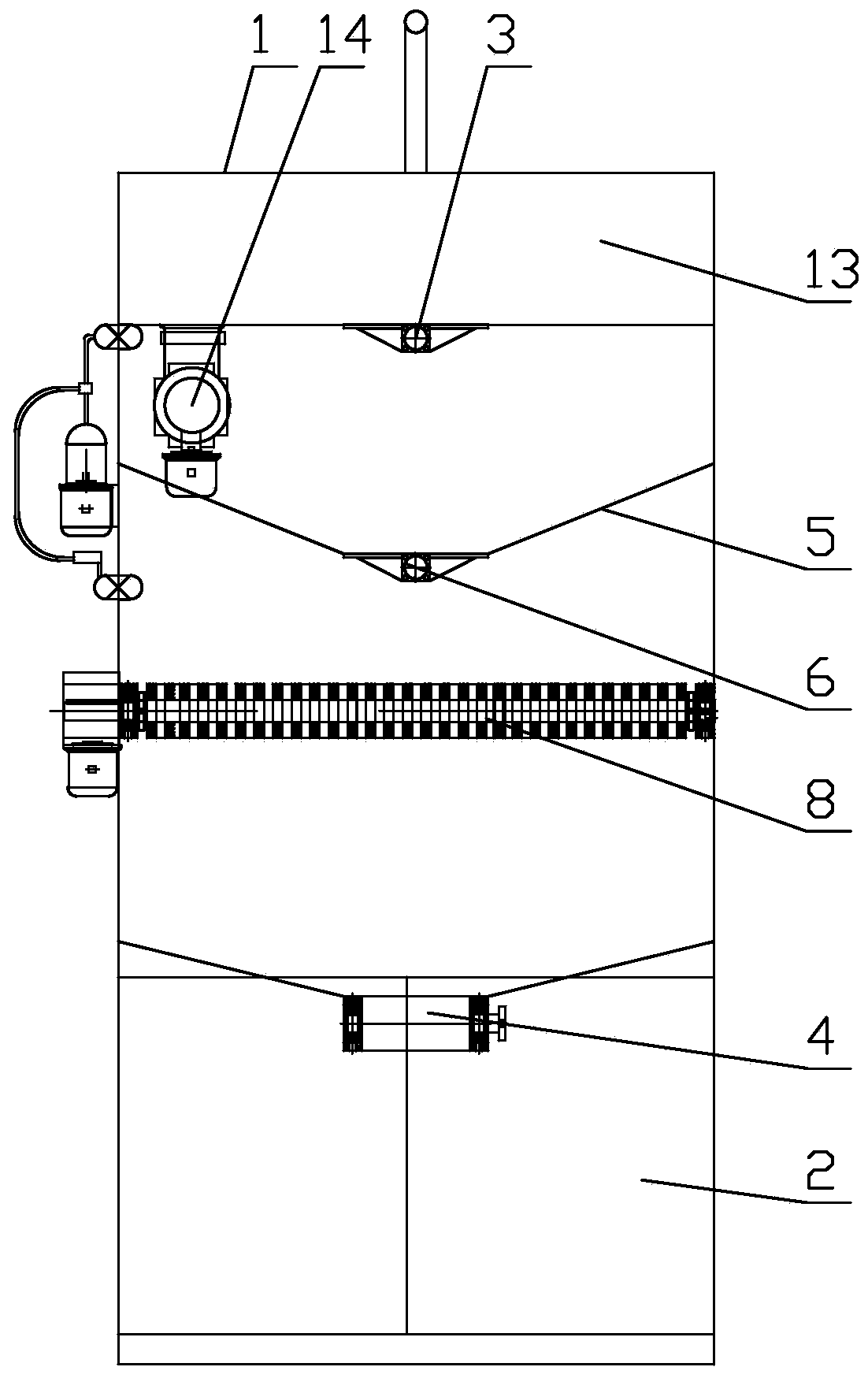

[0071] Such as image 3 As shown, the difference between this embodiment and embodiment 1 is:

[0072] The box body 1 is provided with a crushing mechanism 8 for crushing garbage. The crushing mechanism 8 is located in the cavity of the lowest layer. The crushing mechanism 8 includes two toothed rollers. The teeth of the two rollers are closely matched with the gap. The motor drives the two rollers to rotate in the opposite direction, and the two rollers squeeze inward. Press to crush the trash. The crushing mechanism is a commonly used crushing structure, not limited to one in the drawings of this application, but also other common crushing structures in the industry are within the protection scope of this application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com