Water energy turbine and pump integration machine

A technology of water energy pump and integrated machine, applied in the direction of machine/engine, pump, pump components, etc., can solve the problems of complex installation and large floor space, and achieve overall reduction in volume, simple structure, assembly and post-maintenance. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

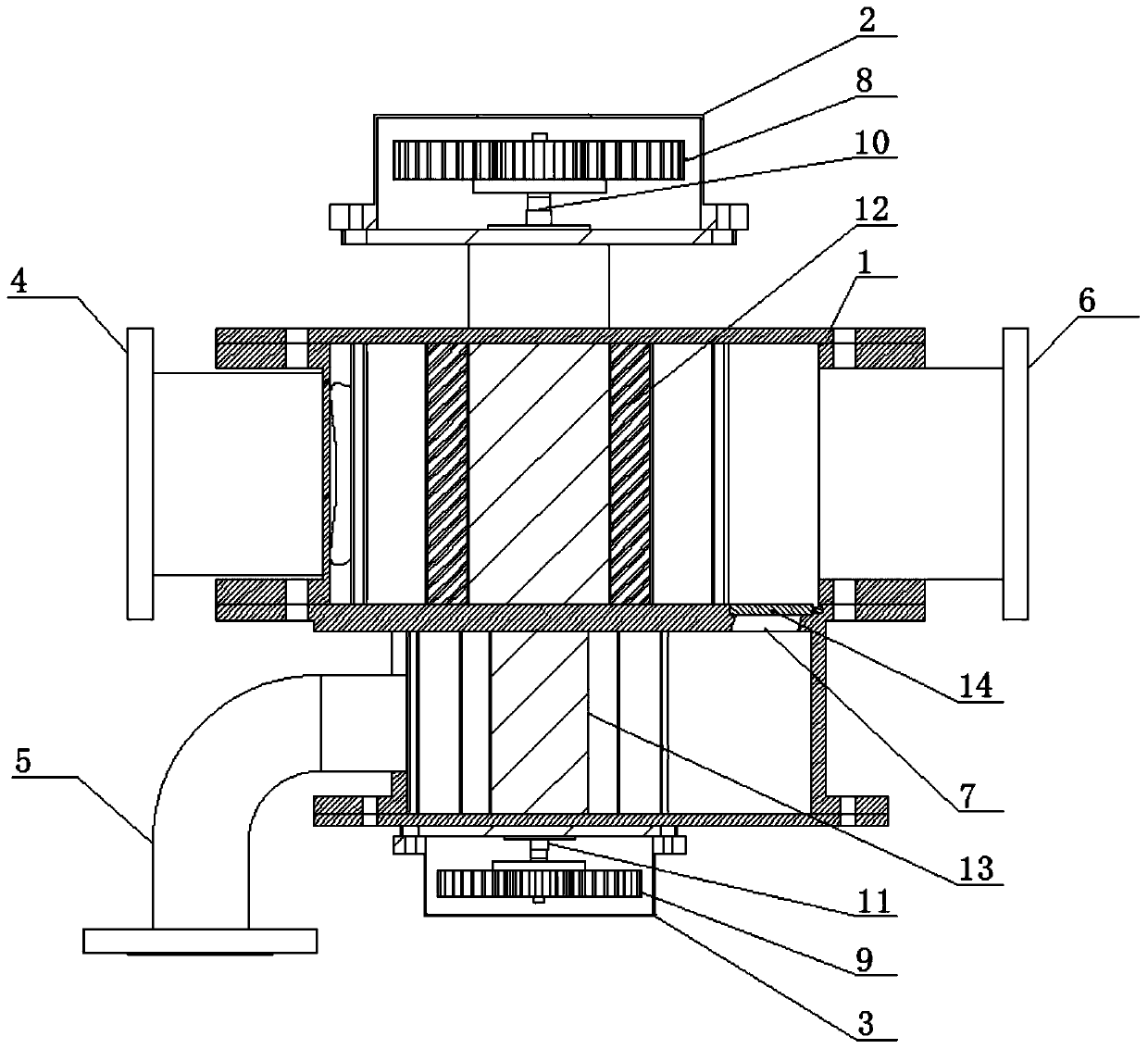

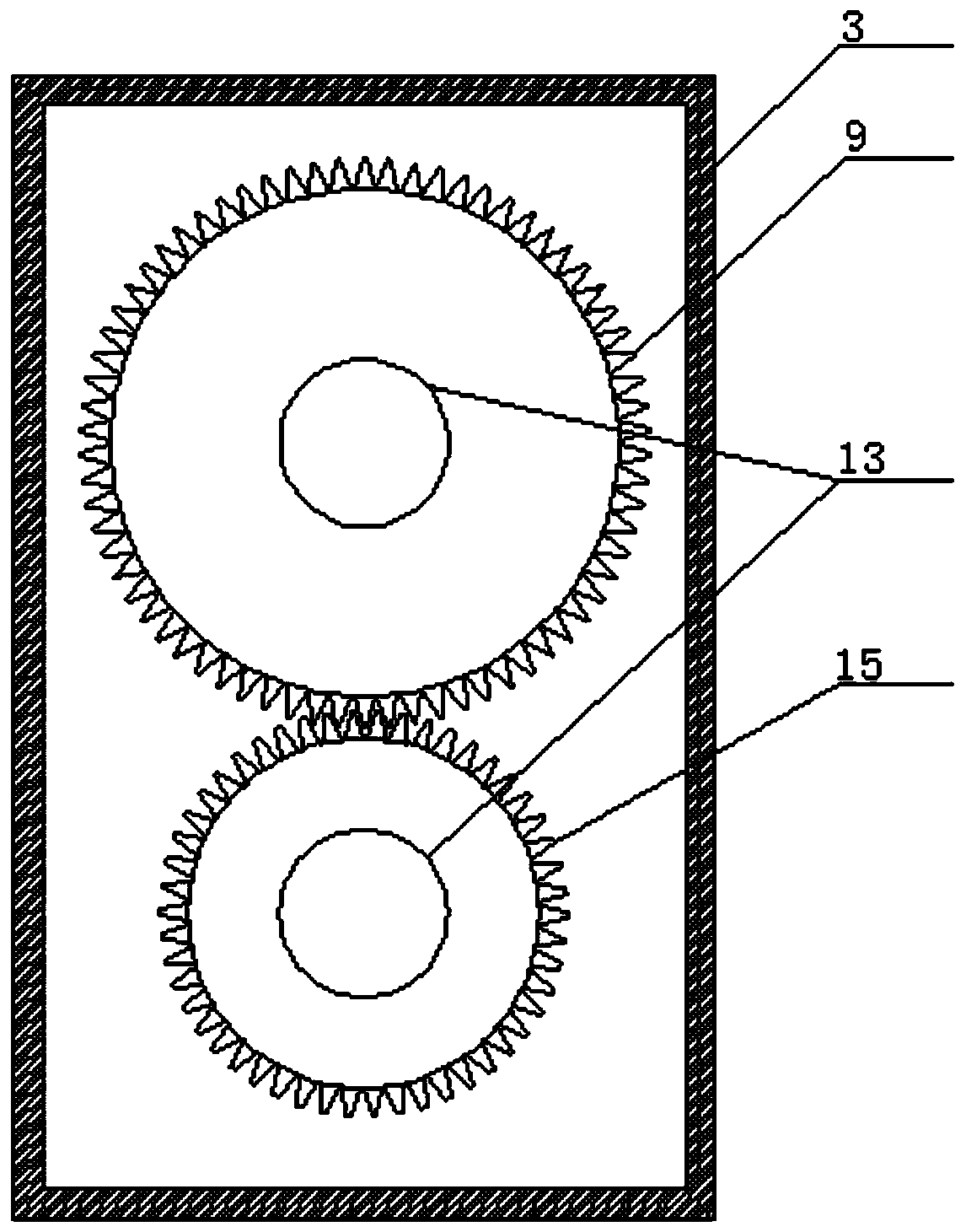

[0015] Embodiment 1, see figure 1 and figure 2 , a water energy machine pump integrated machine, including a housing 1, a water turbine gear box 2, a foam pump gear box 3, a fire water inlet 4, a foam liquid inlet 5, a mixed liquid outlet 6, a foam liquid outlet 7, and a water turbine transmission gear 8 , foam pump transmission gear 9, machine pump connecting shaft 10, foam pump connecting shaft 11, water turbine impeller 12, foam pump rotor 13, non-return device 14, foam pump driven pinion 15; The foam pump and the water turbine share a shell 1, and the drive shafts of the water turbine impeller 12 located on the top of the shell 2 and the foam pump rotor 13 are connected by the same machine-pump connecting shaft 10. As long as the water turbine impeller 12 rotates, it is the same The machine pump connecting shaft 10 can directly drive the foam pump rotor 13 to rotate, and driven by the foam pump gearbox 3, the upper and lower rotors of the foam pump rotate, and the foam l...

Embodiment 2

[0016] Example 2, see figure 1 A non-return device 14 is provided at the outlet 7 of the foam liquid to prevent the water on the turbine side from entering the foam pump side, so as to ensure that the foam liquid is mixed with water at the outlet of the water turbine to form a foam mixture.

Embodiment 3

[0017] Example 3, see figure 1 , figure 2 The water turbine impeller 12 and the foam pump rotor 13 are two groups, which are distributed symmetrically up and down. The two rotors of the foam pump rotate up and down, and the foam liquid is squeezed between the two rotors, so that the foam liquid generates a certain pressure and passes through figure 1 The outlet of the middle foam liquid is injected into the side outlet of the water turbine, which is convenient for adjusting the foam liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com