Method for determining reservoir physical property of sandstone before cementation

A technology of reservoir physical properties and cementation, which is applied in the preparation of test samples, measurement devices, suspensions and porous material analysis, etc., can solve the problem of inaccurate physical properties of sandstone reservoirs, and achieve accurate results without the influence of human factors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following, the present invention will be specifically described through exemplary embodiments. It should be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

[0025] Early strongly cemented sandstone is common in reservoirs, and the physical property evolution of this type of sandstone is usually only affected by early cementation and pre-cementation compaction.

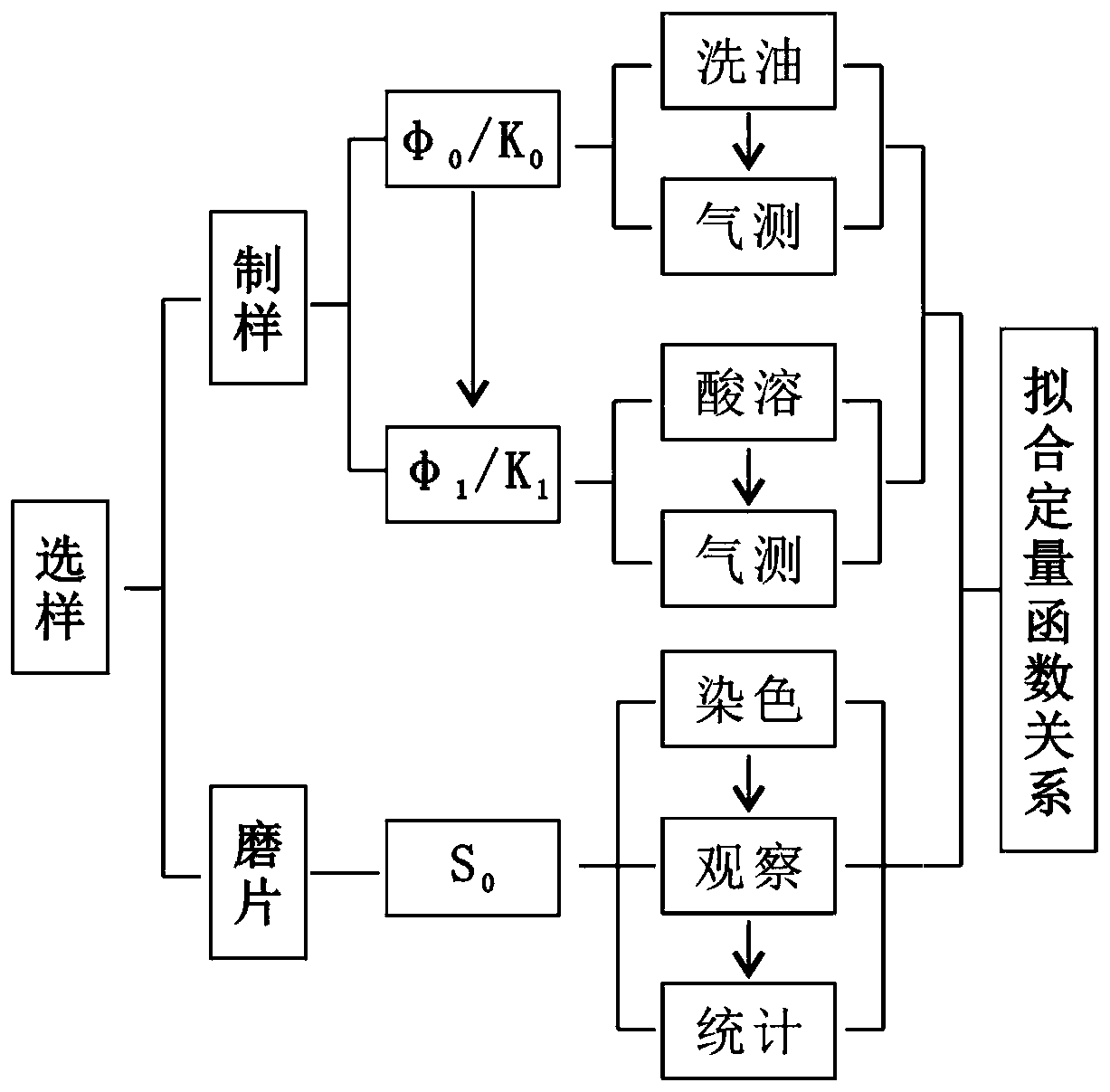

[0026] For the determination of the physical properties of sandstone reservoirs prior to cementation of the above types of rocks, see figure 1 , an embodiment of the present invention provides a method for determining the physical properties of sandstone reservoirs before cementation occurs, and the specific steps are:

[0027] S1. For a certain sandstone reservoir, take a plurality of early-stage strongly cemented rock samples, drill, cut and polish each rock sample to obtain a rock sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com