Industrial part key point detection method based on deep learning

A technology of deep learning and detection methods, which is applied to computer parts, instruments, character and pattern recognition, etc., can solve the problems of sensitivity to image transformation and environment transformation, insufficient stability and robustness, and great image quality constraints. Achieve the effects of increasing generalization ability, reducing regression difficulty, and improving robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

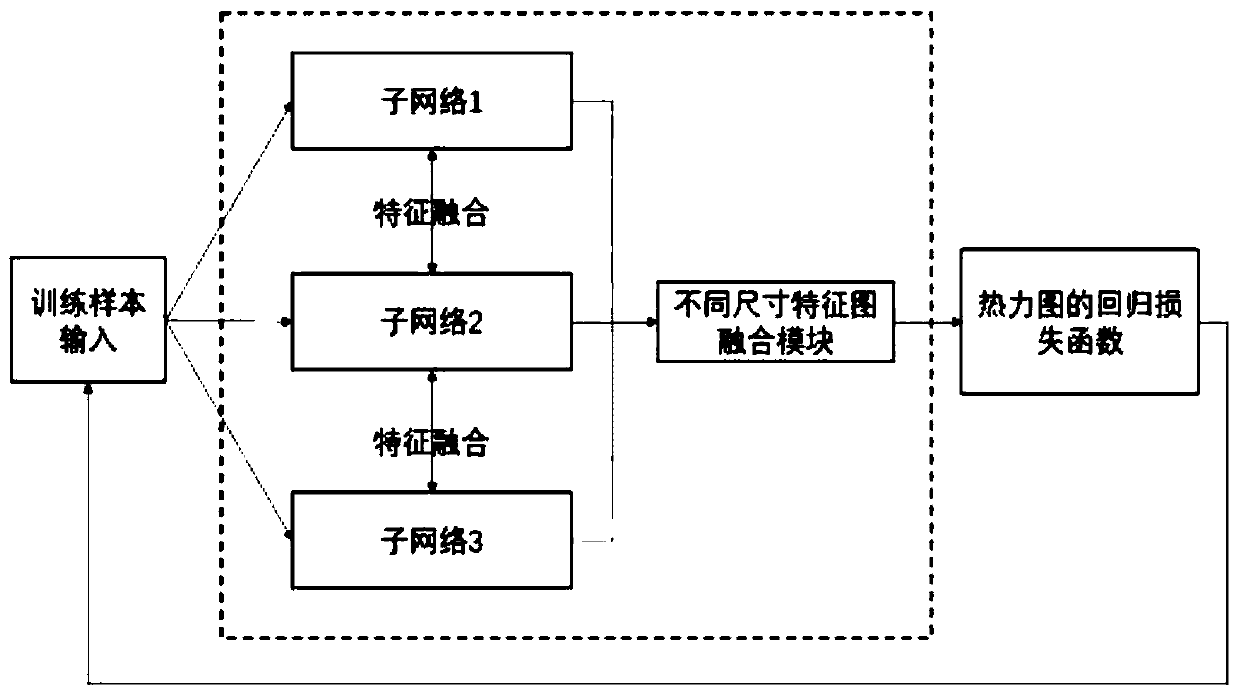

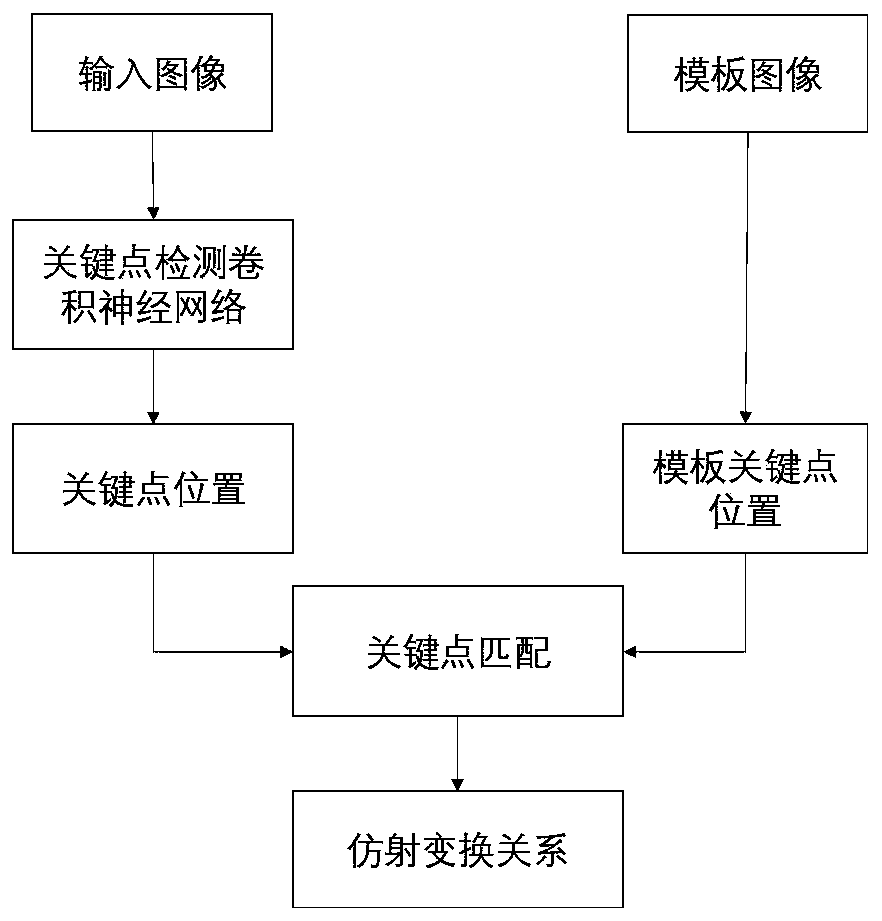

[0046] follow first figure 1 In order to train a network that can detect key points, after obtaining the key point network, according to figure 2 In the order of , use the multi-scale feature map fusion in the key point detection network obtained from the previous training to detect the key points, and then use the key points to match and calibrate the industrial parts through the loss function, such as Figure 4 , Figure 5 and Image 6 As shown, it is the part diagram, thermal diagram and key point diagram applied to the key point detection of the bearing workpiece.

[0047]Using a deep neural network for feature extraction, compared to traditional feature extraction methods, can better deal with the effects of lighting, deformation, rotation, etc., and in addition to the explicit features of the image, the deep neural network can implicitly Learning deeper features can improve the robustness of the overall algorithm.

[0048] Using multi-scale feature map fusion, the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com