Design method of three-dimensional elastic model of suspended tunnel and three-dimensional elastic model

A floating tunnel and elastic model technology, which is applied in the design field of three-dimensional elastic models and three-dimensional elastic models of floating tunnels, can solve problems such as the inability to obtain the real physical response laws of floating tunnels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

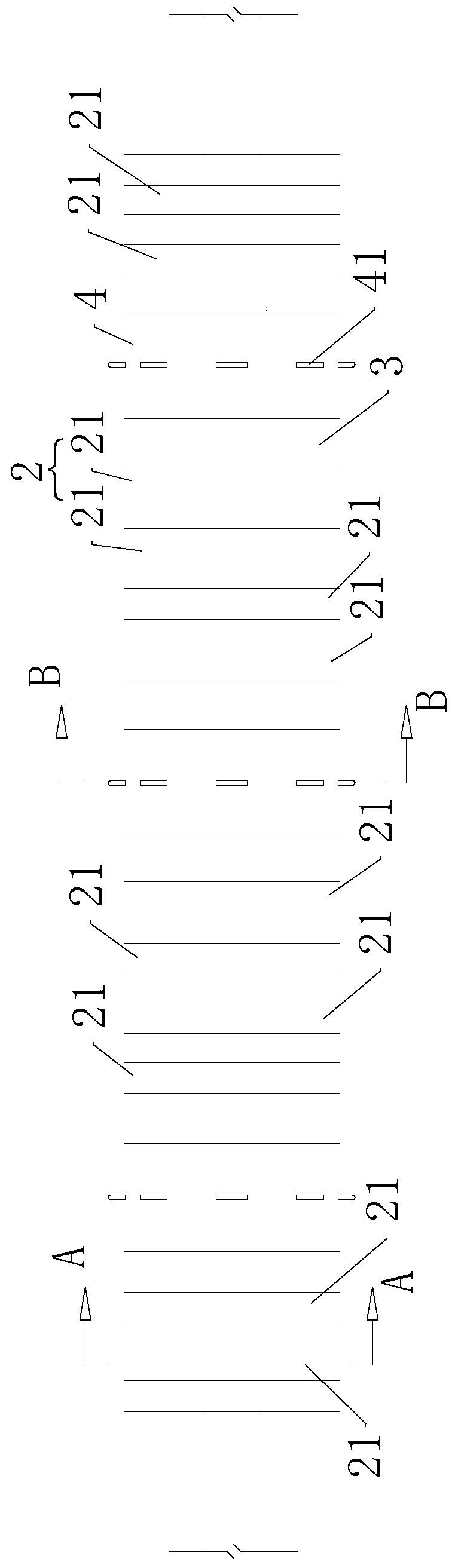

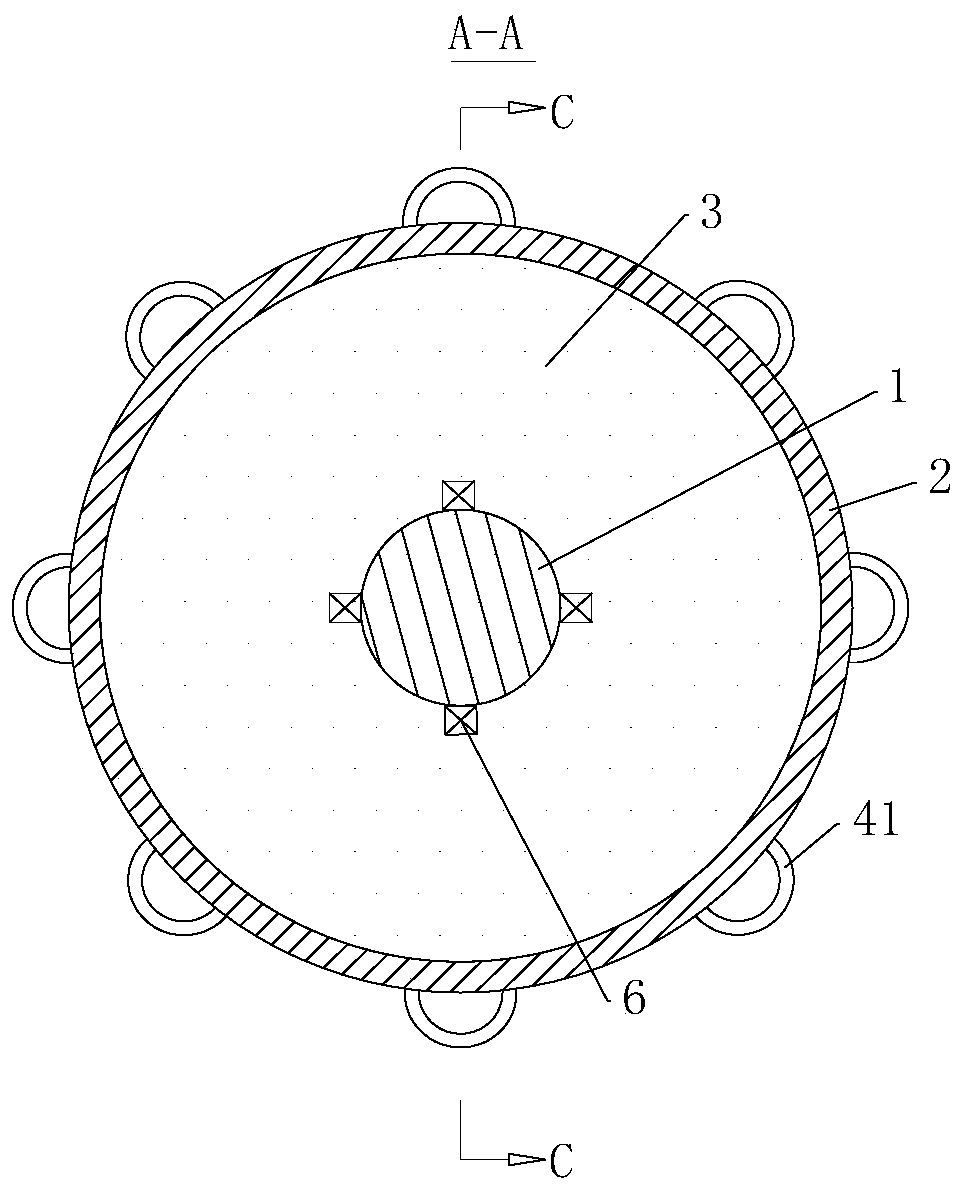

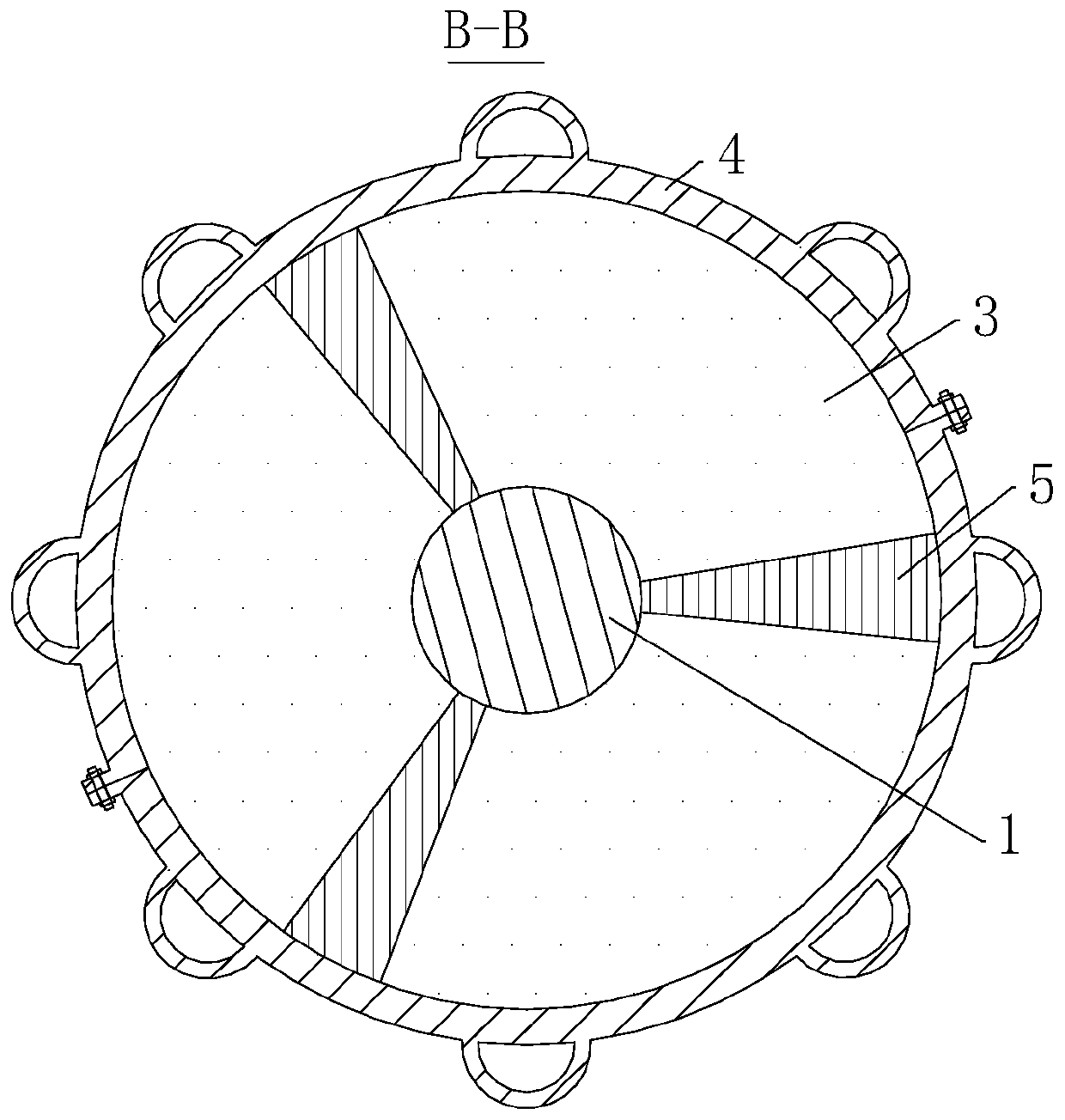

[0085] see Figure 1-Figure 9 , the embodiment of the present invention provides a three-dimensional elastic model of the floating tunnel, the three-dimensional elastic model of the floating tunnel is geometrically similar to the prototype, the ratio of the total gravity satisfies the Froude similarity criterion and the ratio of the bending stiffness meets the elastic similarity. The prototype described in this embodiment refers to: during the experiment, considering the material and design size of the floating tunnel that may be used in the actual project, as well as the simulation ability of the experimental environment, the material and size of the floating tunnel used for simulation in this experiment are selected . The three-dimensional elastic model of the floating tunnel in this embodiment is designed through the following steps:

[0086] S1. Determine the size scale ratio λ and the size, gravity and bending stiffness parameters of the prototype of the three-dimensiona...

Embodiment 2

[0150] see Figure 10-Figure 12 , the present embodiment provides a three-dimensional elastic model of a floating tunnel, its design method and structure are basically the same as those of the three-dimensional elastic model of the floating tunnel in Embodiment 1, and the structural difference is that in this embodiment, the counterweight 21 structure is different.

[0151] In this embodiment, the counterweight 21 adopts a block structure. In order to adapt to the structure of the counterweight 21, the third structural member 3 is no longer divided into a large-diameter block and a small-diameter block, but the third structural member is set as an integral structure, and then opened on the third structural member 3 Groove, the size of the groove is adapted to the size of the counterweight 21. Further, the grooves are uniformly distributed in the axial direction of the model, and the grooves are also uniformly distributed in the circumferential direction of the model.

[015...

Embodiment 3

[0156] see Figure 13 and Figure 14 , the embodiment of the present invention provides a three-dimensional elastic model of a floating tunnel, its design method and structure are basically the same as those in Embodiment 2, the difference in its structure is: in this embodiment, the pipe section 11 is set as a hollow tubular structure, That is: the cross section of the pipe section 11 is annular.

[0157] In the three-dimensional elastic model of the floating tunnel provided in this embodiment, the cross-section of the pipe section 11 is also obtained by calculating the bending stiffness. On the basis of obtaining the cross-sectional area of the pipe section 11 and the design length of the prototype, the first structural member can be obtained 1, so that according to the gravity of the first structural member 1 and the requirement of Floyd’s criterion, the gravity to be provided by the second structural member 2 is obtained, that is, the total gravity of the counterweight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com