Vibration Energy Harvester Based on Various Magnetic Phase Change Alloys

A vibration energy collection and alloy-based technology, applied in electromechanical devices, electrical components, etc., can solve the problems of low power conversion efficiency, low energy conversion efficiency, and reduced magnetic induction intensity, so as to avoid magnetic flux leakage and accelerate magnetic conversion rate , the effect of increasing the amount of change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

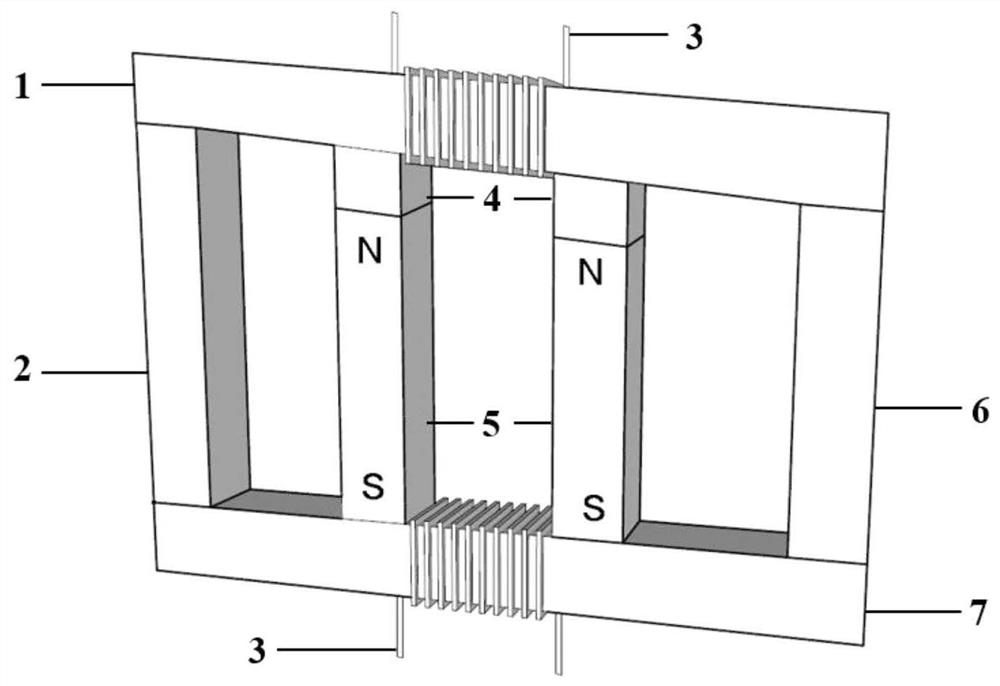

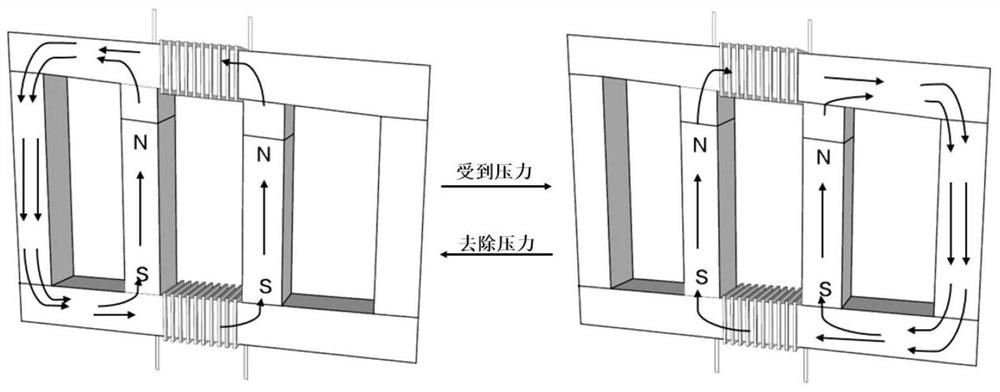

[0035] Such as Figure 1-2 As shown, the present invention discloses a vibration energy harvester based on a magnetic phase change alloy. The vibration energy harvester consists of an upper yoke 1, a lower yoke 7, a coil 3, a Heusler type alloy 2, and a MnCoSi-based alloy 6 , iron powder, silicon rubber and permanent magnet 5 are prepared.

[0036]The preparation process of the vibration energy harvester of the present invention is: firstly fix the Heusler type alloy 2 and the MnCoSi-based alloy 6 vertically on the two ends of the lower yoke respectively, and two permanent magnets 5 are then fixed in the middle of the lower yoke; The liquid A and liquid B that make up the silicone rubber are uniformly mixed in the corresponding mass ratio to obtain a liquid, and then iron powder is mixed into it, and the corresponding buffer layer 4 is obtained after natural cooling and solidification, and then bonded to the upper part of the permanent magnet 5, and buffered after curing The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com