Shifting fork type mechanism for stopping transplanting in backward movement and rice transplanter

A technology of fork type and fork assembly, which is applied to transplanting machinery, controlled components, mechanical equipment, etc., can solve the problems of poor reliability, one-way clutch heating, high failure rate, simple and reliable structure, and increased self-locking. The effect of strong force and environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

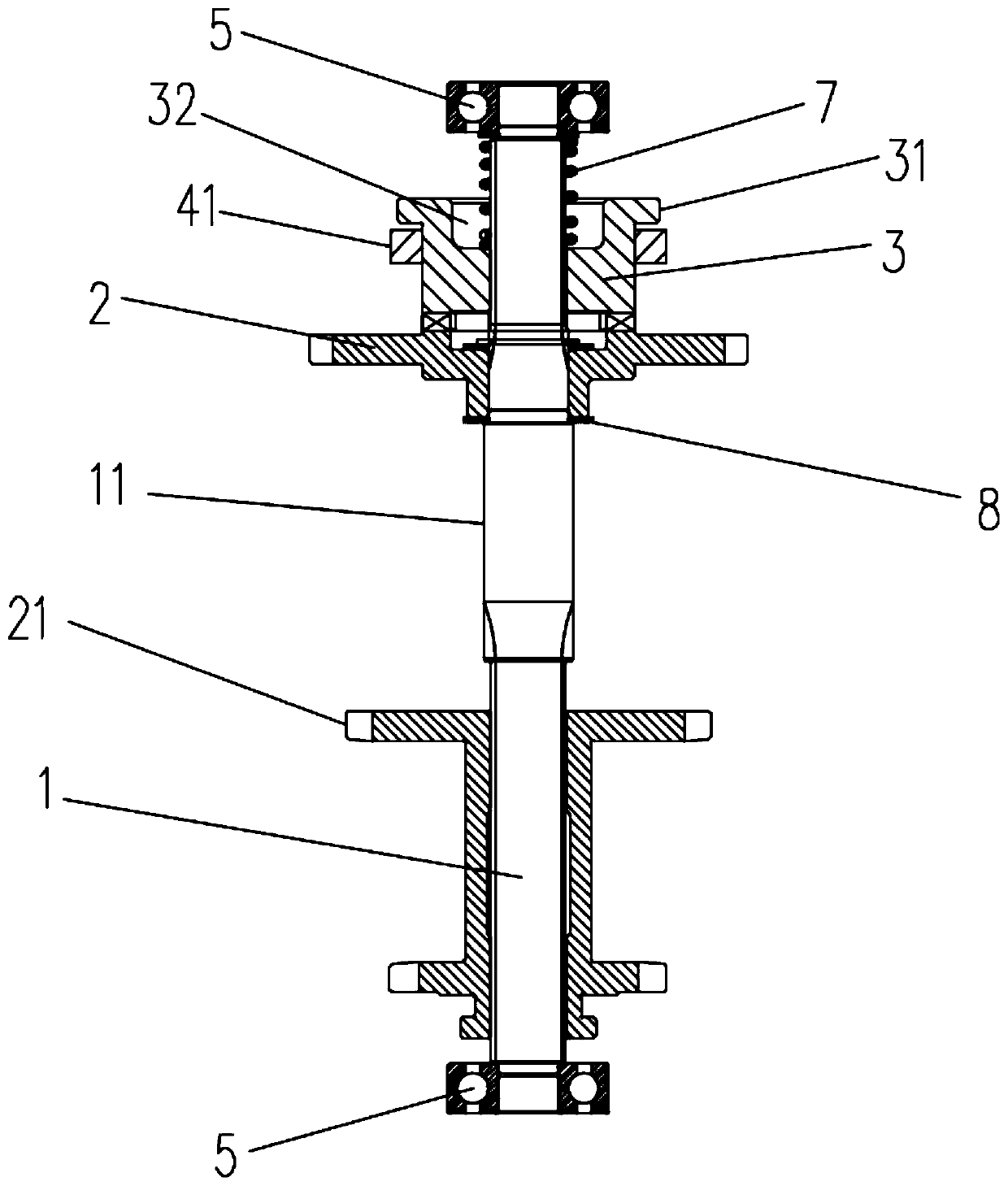

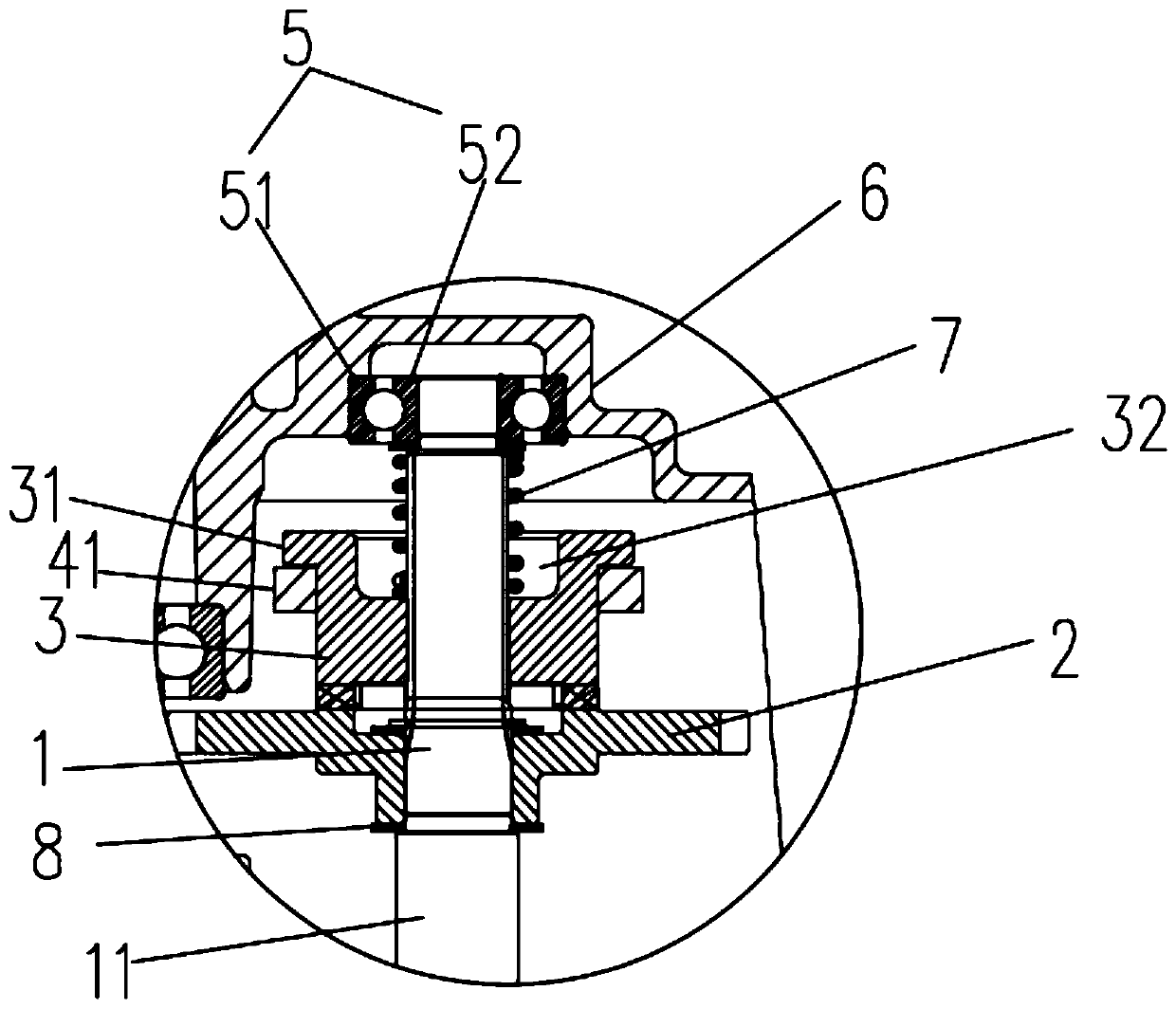

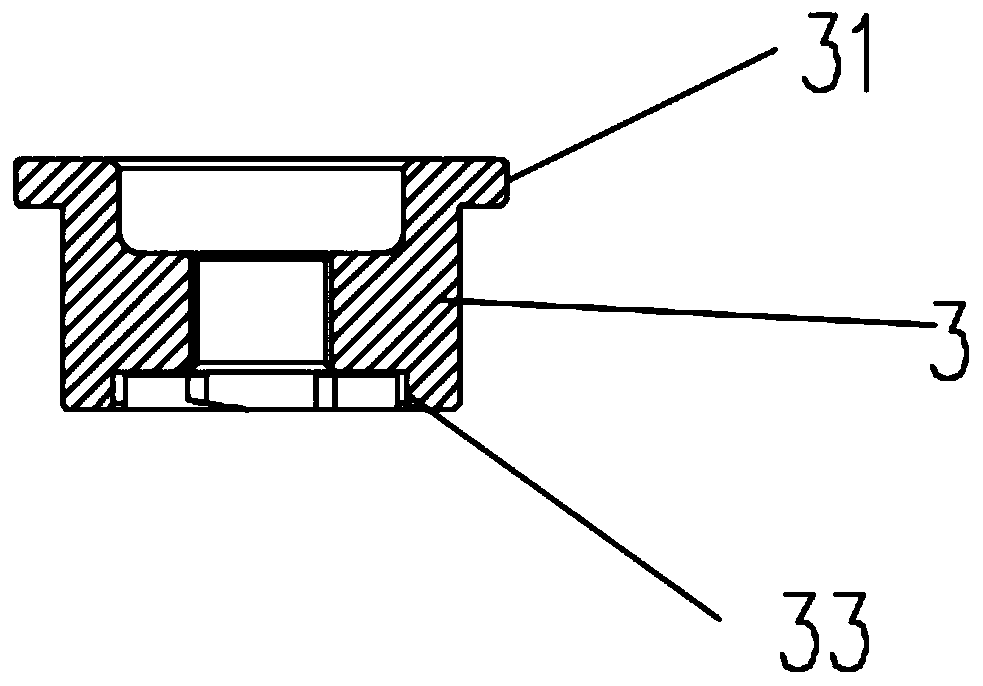

[0037] Such as Figure 1-Figure 6 As shown, the embodiment of the fork-type reverse non-planting mechanism disclosed by the present invention includes a fork assembly, a rice-planting power input shaft 1, a rice-planting input gear 2, a clutch 3 and a spring 7, and the two ends of the rice-planting power input shaft 1 respectively pass through The bearing 5 is rotationally connected with the inner walls on both sides of the gearbox 6. The input gear 2, the clutch 3 and the spring 7 are all socketed on the power input shaft 1 for rice transplanting. The input gear 2 for rice transplanting is an idler gear. The power input shaft 1 is connected by transmission, the surface of the rice transplanting power input shaft 1 has a limiting portion 11, the rice transplanting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com