Puffing compound feed for culturing mandarin fish on circulating water runway and preparation method of puffing compound feed

A technology of extruded compound feed and circulating water, which is applied in the field of feed, can solve the problems of uneven quality and energy consumption of fish, and achieve the effects of enhancing digestion and absorption, promoting healthy and rapid growth of fish, and improving feeding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

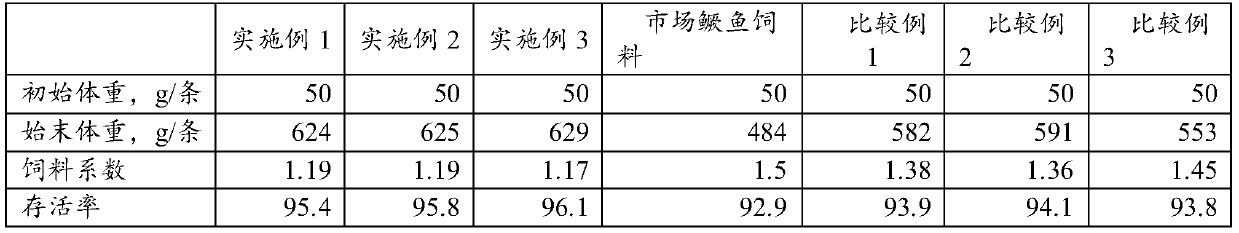

Examples

preparation example Construction

[0072] The present invention provides a method for preparing the puffed compound feed for mandarin fish cultured in a circulating water runway described in any one of the above technical solutions, comprising:

[0073] White fish meal, frog meal, fish meal, starch, shrimp meal, fermented soybean meal, hemoglobin powder, brewer's yeast, Daphnia magna powder, soybean lecithin powder, minerals, multidimensional, calcium dihydrogen phosphate, choline chloride, taurine Acid and antioxidant are mixed, pulverized, prepared, puffed, dried, then vacuum sprayed with mixed oil, and cooled.

[0074] The preparation method of puffed mandarin fish puffed compound feed for circulating water runway culture of the present invention firstly mixes white fish meal, frog meal, fish meal, starch, shrimp meal, fermented soybean meal, blood globulin powder, brewer's yeast, large daphnia powder, soybean lecithin powder, mineral matter , multidimensional, calcium dihydrogen phosphate, choline chloride,...

Embodiment 1

[0091] An extruded compound feed for cultivating mandarin fish in a circulating water racetrack is prepared by mixing the following raw materials in parts by weight: 40 parts of imported white fish meal, 10 parts of frog meal, 10 parts of domestic fish meal, 12 parts of starch, 5 parts of shrimp meal, fermented 5 parts of soybean meal, 5 parts of hemoglobin powder, 2 parts of brewer's yeast, 3 parts of daphnia daphnia powder, 3 parts of soybean lecithin powder, 2 parts of mixed oil composed of fish oil and soybean oil with a mass ratio of 1:1, mineral matter (0.2 parts by weight of copper sulfate , 2.0 parts by weight of ferrous sulfate, 2.5 parts by weight of amino acid boiled zinc, 0.65 parts by weight of manganese sulfate, 1.2 parts by weight of cobalt chloride, 0.7 parts by weight of sodium selenite, 0.9 parts by weight of calcium iodate, 2.8 parts by weight of magnesium sulfate) 2 parts, multidimensional (vitamin A is 0.10 parts by weight, vitamin D 3 0.08 parts by weigh...

Embodiment 2

[0094] A kind of puffed compound feed for mandarin fish cultured in a circulating water track, which is made by mixing the following raw materials in parts by weight: 45 parts of imported white fish meal, 7.5 parts of frog meal, 8 parts of domestic fish meal, 14 parts of starch, 3 parts of shrimp meal, fermented 7 parts of soybean meal, 3 parts of hemoglobin powder, 2 parts of brewer's yeast, 2 parts of Daphnia daphnia powder, 2 parts of soybean lecithin powder, 3 parts of mixed oil composed of fish oil and soybean oil with a mass ratio of 1:1, mineral matter (0.2 parts by weight of copper sulfate , 2.0 parts by weight of ferrous sulfate, 2.5 parts by weight of amino acid boiled zinc, 0.65 parts by weight of manganese sulfate, 1.2 parts by weight of cobalt chloride, 0.7 parts by weight of sodium selenite, 0.9 parts by weight of calcium iodate, 2.8 parts by weight of magnesium sulfate) 2 parts, multidimensional (vitamin A is 0.10 parts by weight, vitamin D 3 0.08 parts by weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com