Waste collecting device for paper product processing equipment

A technology for processing equipment and waste collection, which is applied in the field of waste collection devices for paper processing equipment, can solve the problems of increasing the number of replacement of storage carts, high risk of personnel work, waste of manpower and time, etc., so as to save the replacement of storage carts and increase The effect of increasing the storage capacity and improving the use and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

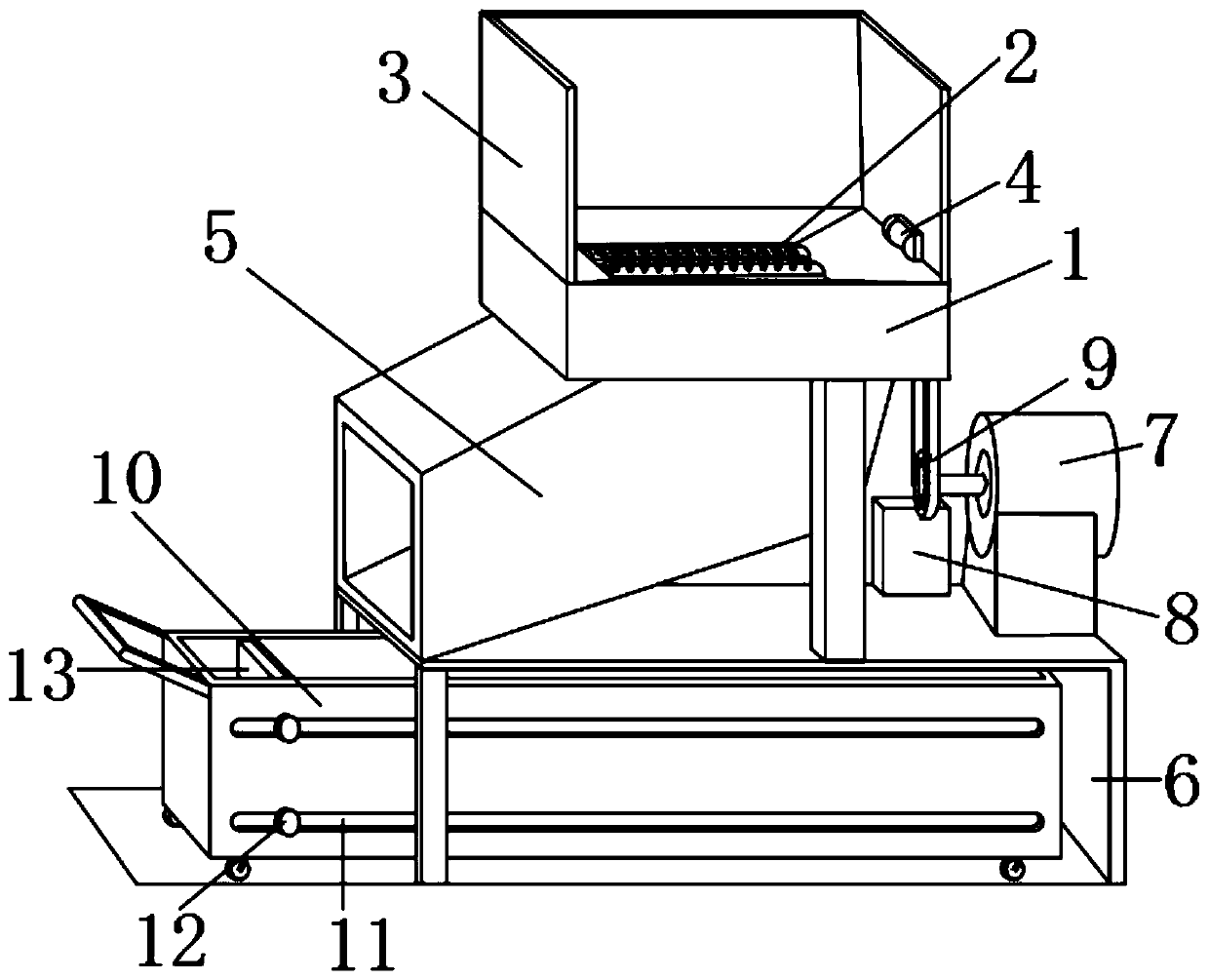

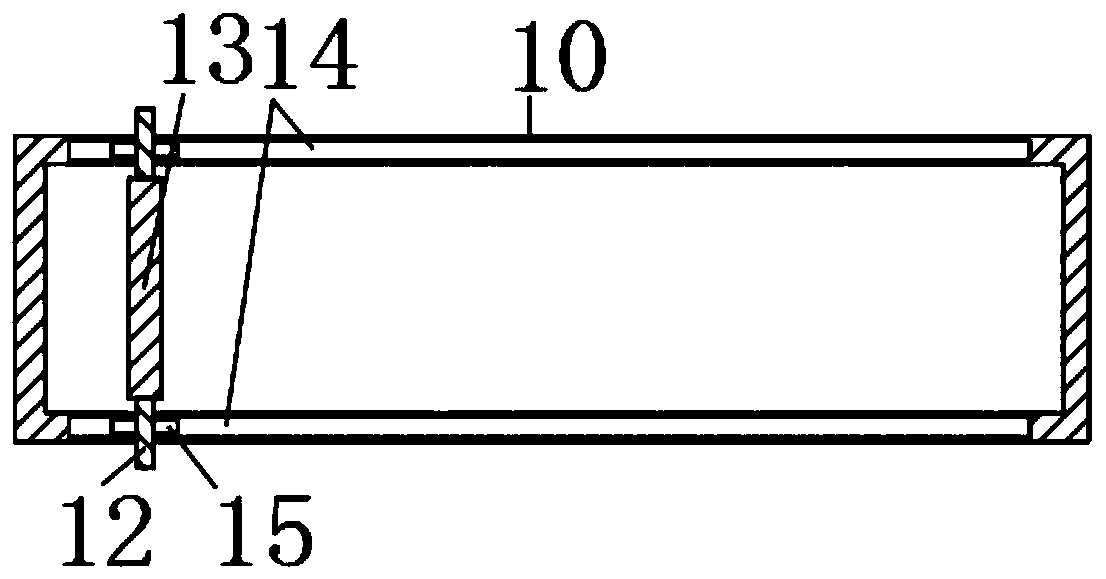

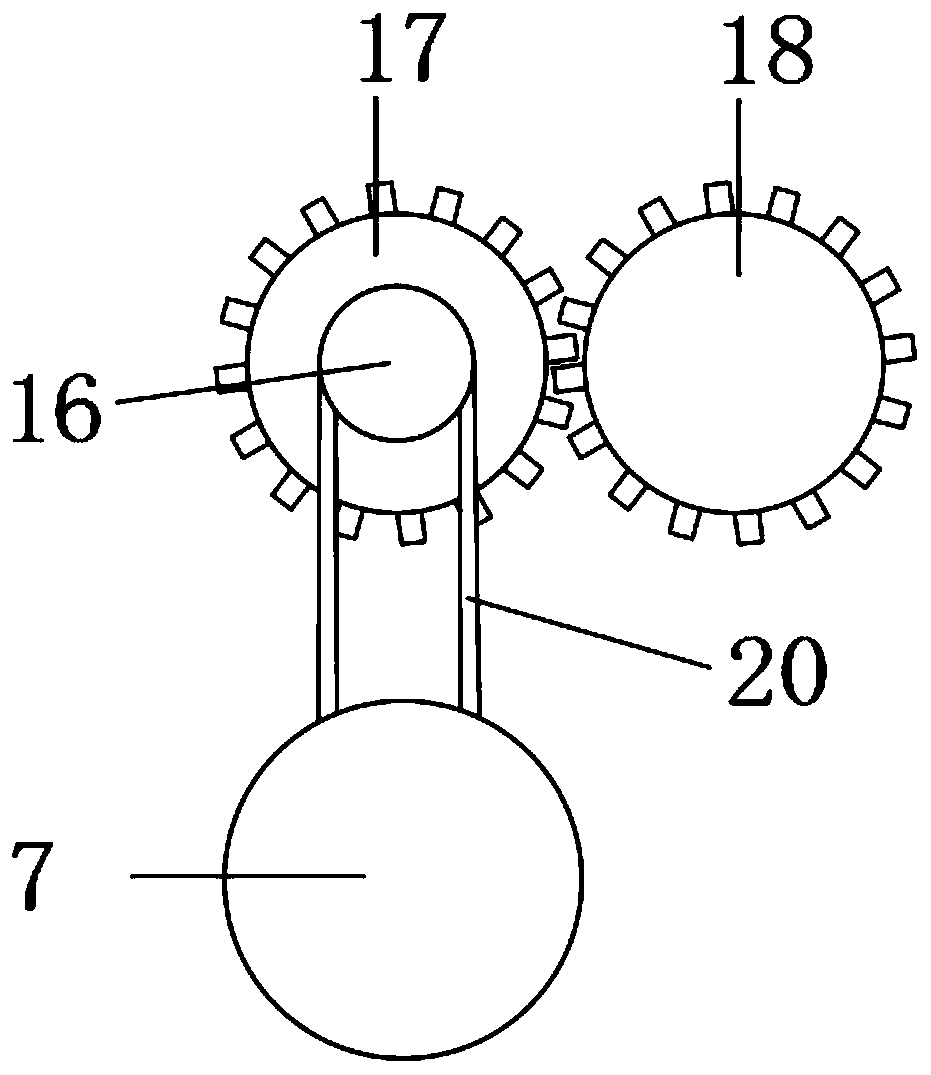

[0020] Such as Figure 1-4 As shown, a waste collection device for paper product processing equipment includes a roller box 1, and shredding rollers 2 are movably installed in the front and back of the inside of the roller box 1, and the upper surface edge of the roller box 1 is fixed A baffle 3 is installed, a human body detector 4 is fixedly installed on the inner side of the surface of the baffle 3 close to the bottom, and an excretion channel 5 is fixedly installed on the lower surface of the roller box 1, and the lower surface of the excretion channel 5 is fixedly installed There is a support frame 6, the upper surface of the support frame 6 is located on one side of the discharge channel 5, and a power distribution box 8 is fixedly installed, and the upper surface of the support frame 6 is located on one side of the distribution box 8, and a power motor 7 is fixedly installed A driving wheel 9 is fixedly installed on one side of the power motor 7, and a storage cart 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com