Mounting device for wind power blade flasher

A wind power blade and installation device technology is applied in the field of wind power blade air-termination installation devices, which can solve the problems of inaccurate positioning, incomplete fastening of air-termination devices, and easy deviation of manually punched installation holes, so as to reduce operating strength and Difficulty, wide range of use, effect of installation and tightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that the terms "comprising" and "having" and any variations thereof in the present invention are intended to cover non-exclusive inclusion, for example, a process, method, system, product or device that includes a series of steps or units does not necessarily Restricted to those steps or elements explicitly listed, but may include other steps or elements not explicitly listed or inherent to the process, method, product or apparatus.

[0031] The core of the present invention is to provide a wind power blade air-termination installation device, which can effectively accurately locate the position where the wind power blade needs to be installed with the air-termination device, ensure the accuracy and verticality of the hole during the drilling process, and enable Lightning receptors are installed securely.

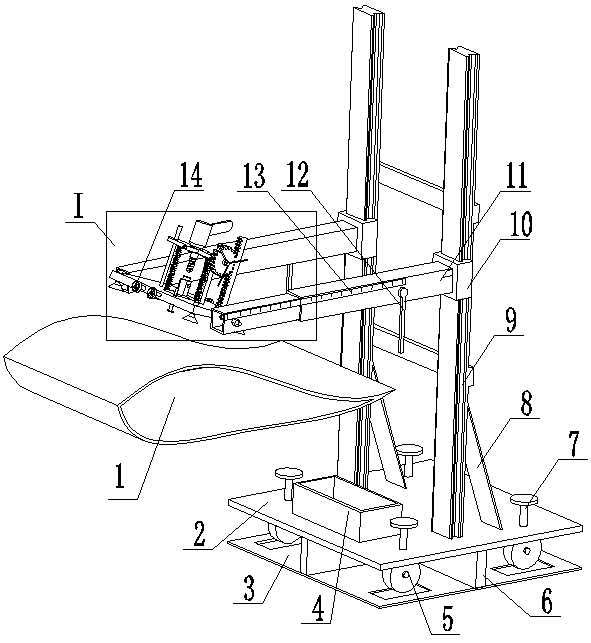

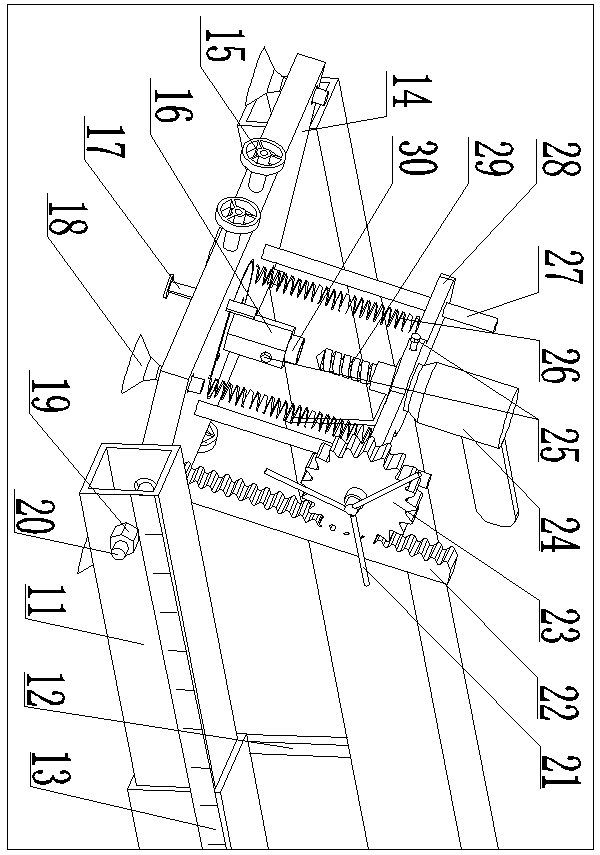

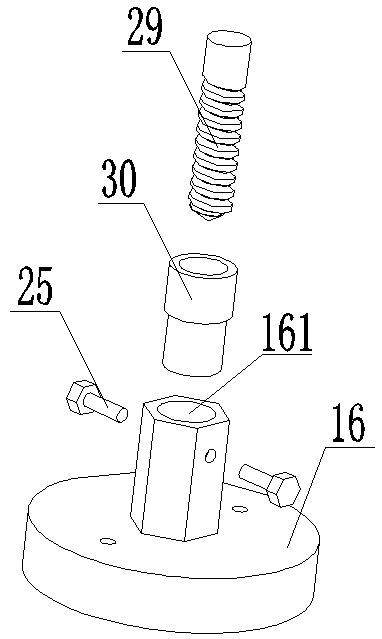

[0032] Please refer to figure 1 , figure 1 Schematic diagram of the structure provided by the present invention.

[0033] A wind power blade ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com