Prefabricated type cross laminated timber concrete multiple-layer core cylinder structure

A prefabricated concrete and prefabricated assembly technology, applied in special structures, building components, building structures, etc., can solve the problems of low comprehensive economic benefits, large human and financial resources, environmental pollution, etc., to save human and financial resources, improve fire performance, construction Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

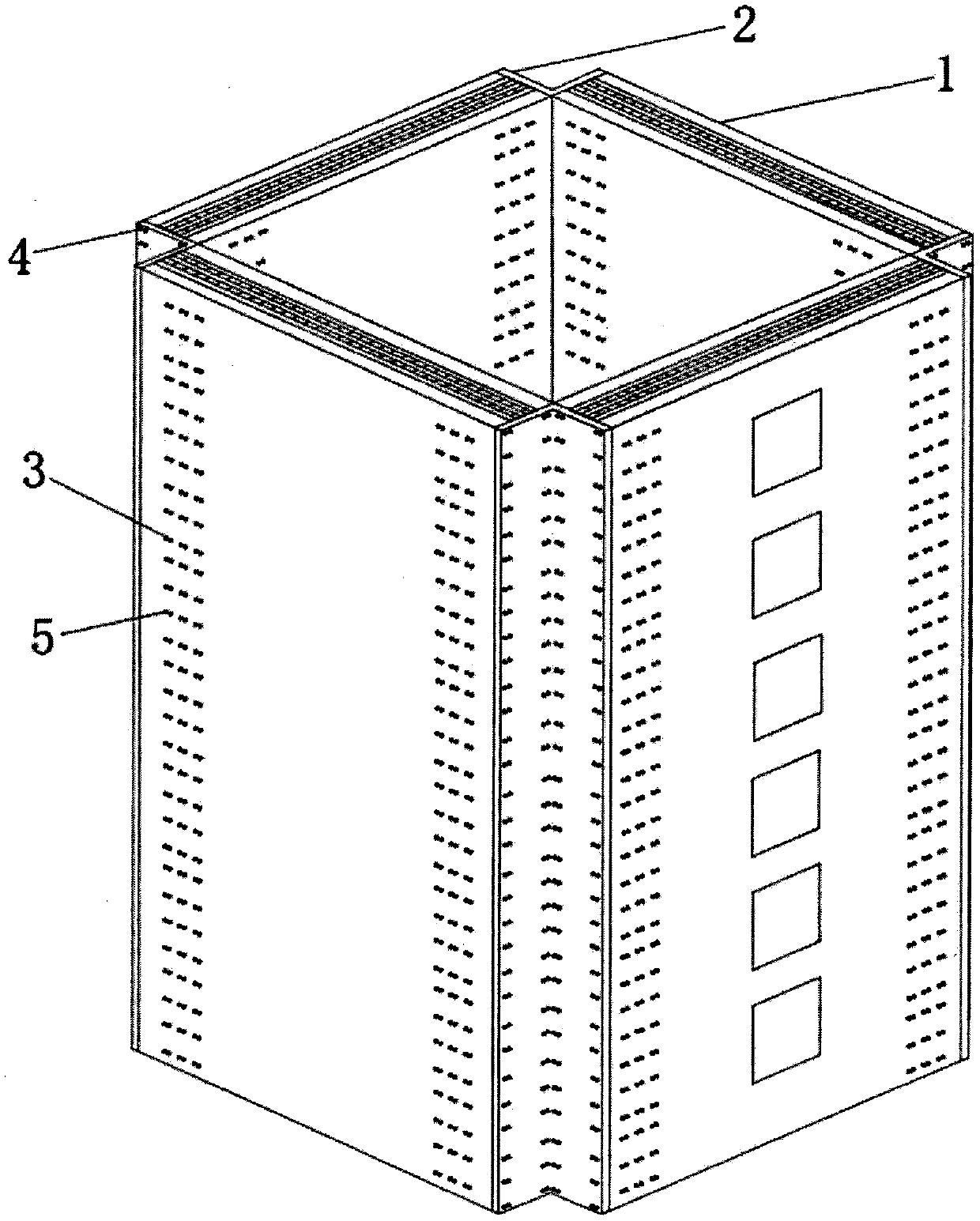

[0027] Such as Figure 1-6 As shown, the prefabricated cross-laminated timber concrete clad core tube structure includes: clad shear walls 1 , equilateral angle steel 2 , bolts 3 , and nuts 4 .

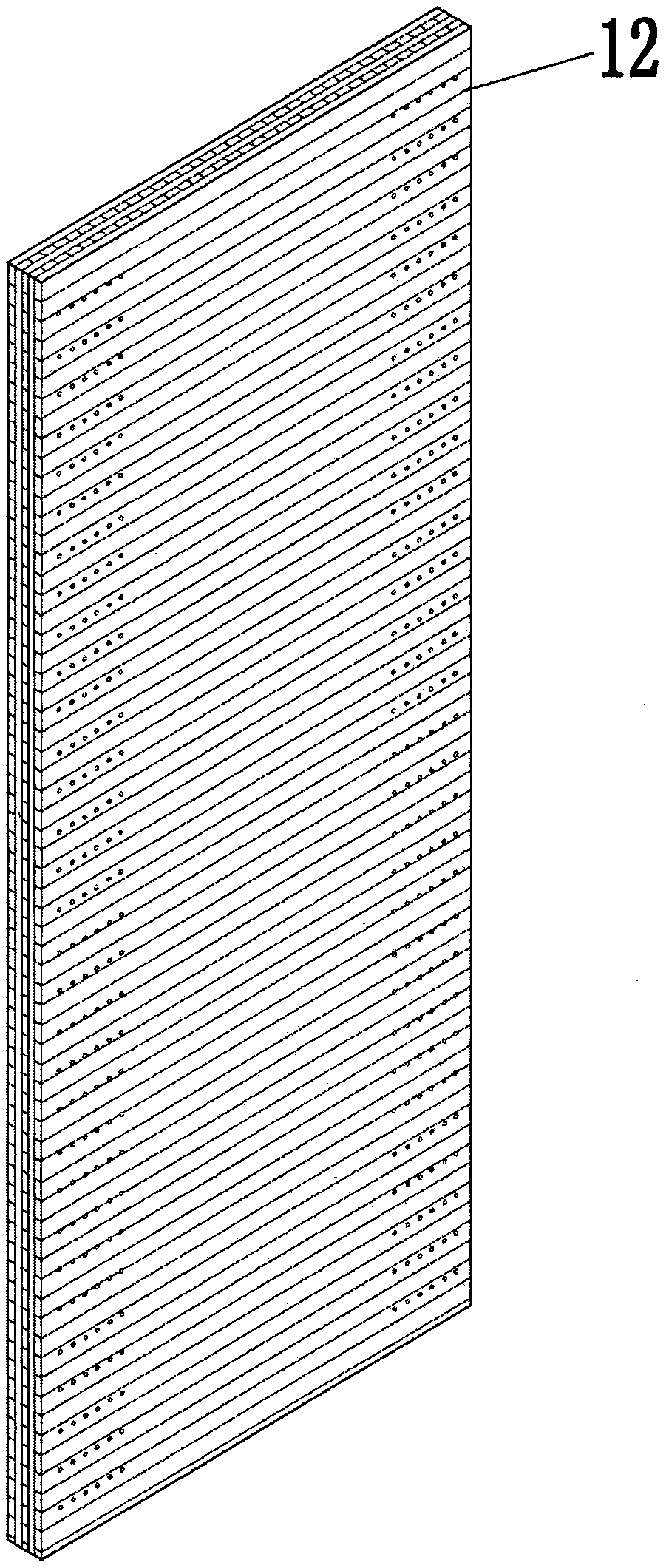

[0028] The composite shear wall 1 is composed of an outer prefabricated concrete wall 11 , an interlayer cross-glued wood board 12 , an inner prefabricated concrete wall 13 and embedded bolts 14 .

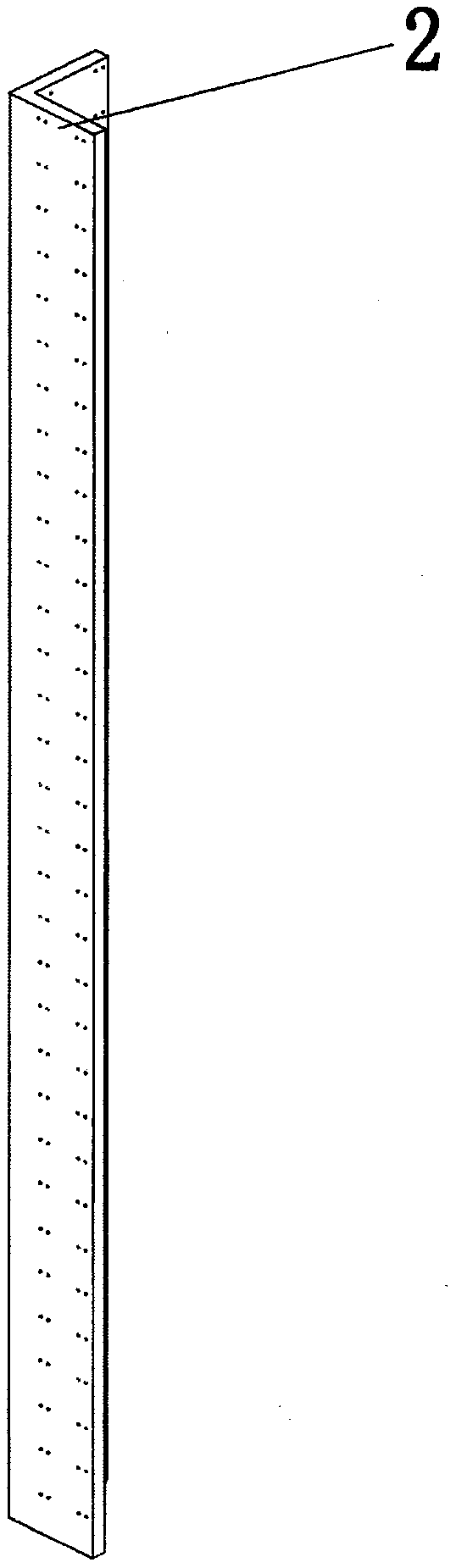

[0029] The composite shear wall 1 is reserved with bolt holes, the outer precast concrete wall 11 is reserved with bolt holes, the interlayer cross-glued wood board 12 is reserved with bolt holes, and the inner precast concrete wall 13 is reserved with bolt holes. The angle steel 2 is reserved with bolt holes corresponding to the bolt holes.

[0030] The adjacent composite shear walls 1 are anchored together by equilateral angle steel 2 through embedded bolts 14;

[0031] Among them, the width of the equilateral angle steel 2 is the same as the thickness of the composite shear wall 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com