Warehouse operation control method, device and system

An operating system and warehouse technology, applied in data processing applications, instruments, computing, etc., can solve the problems of frequent handling, high cost of transportation vehicles, large transportation vehicles, etc., to achieve software and hardware cost control, improve operation efficiency, and save labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

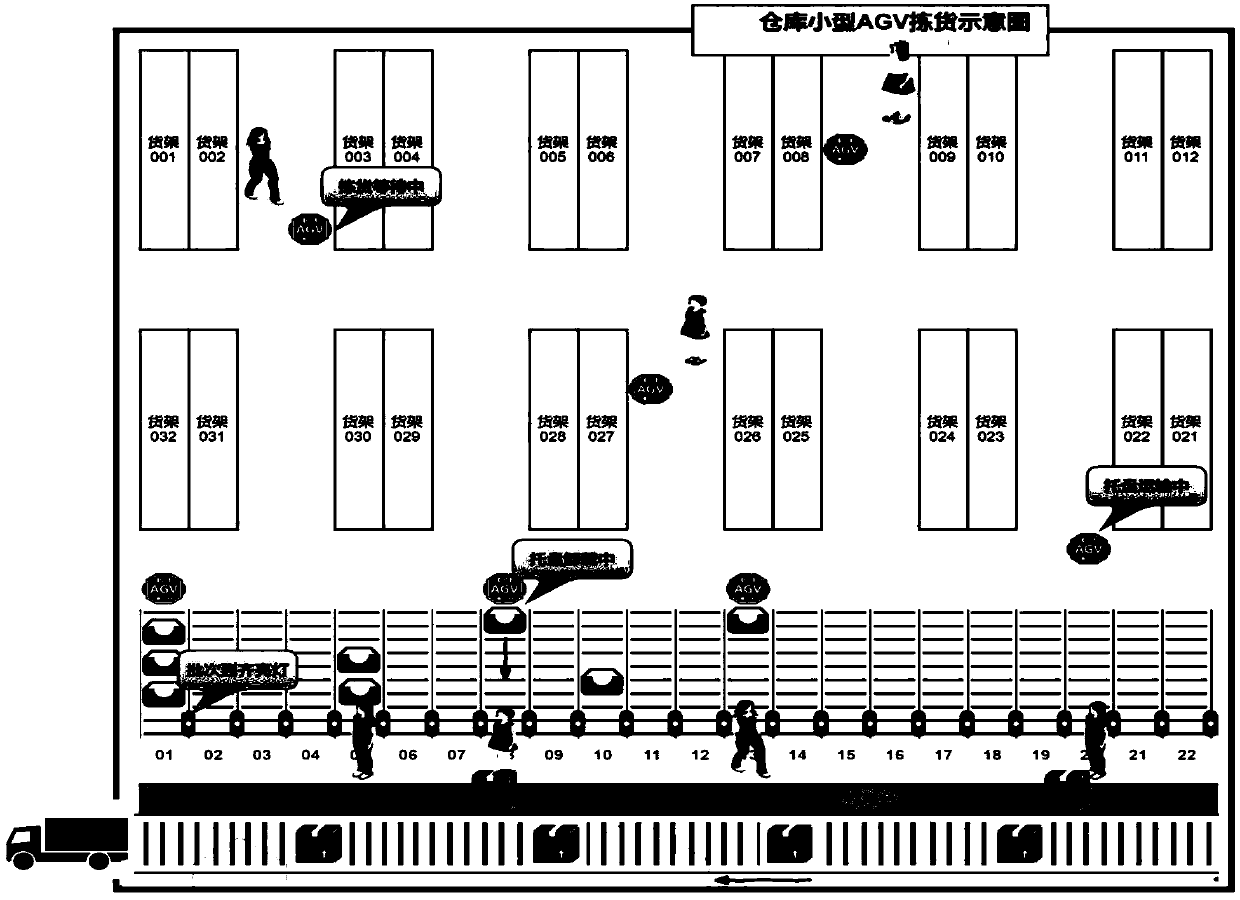

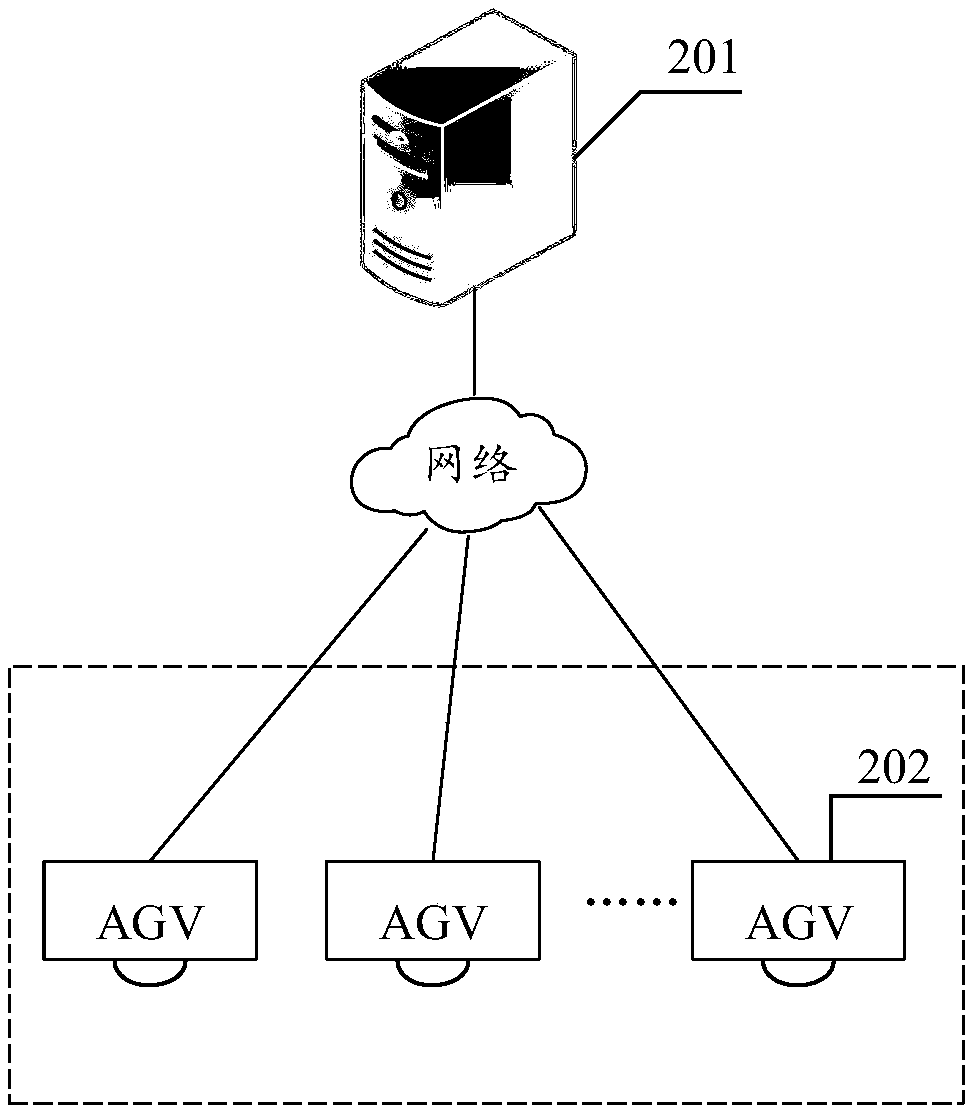

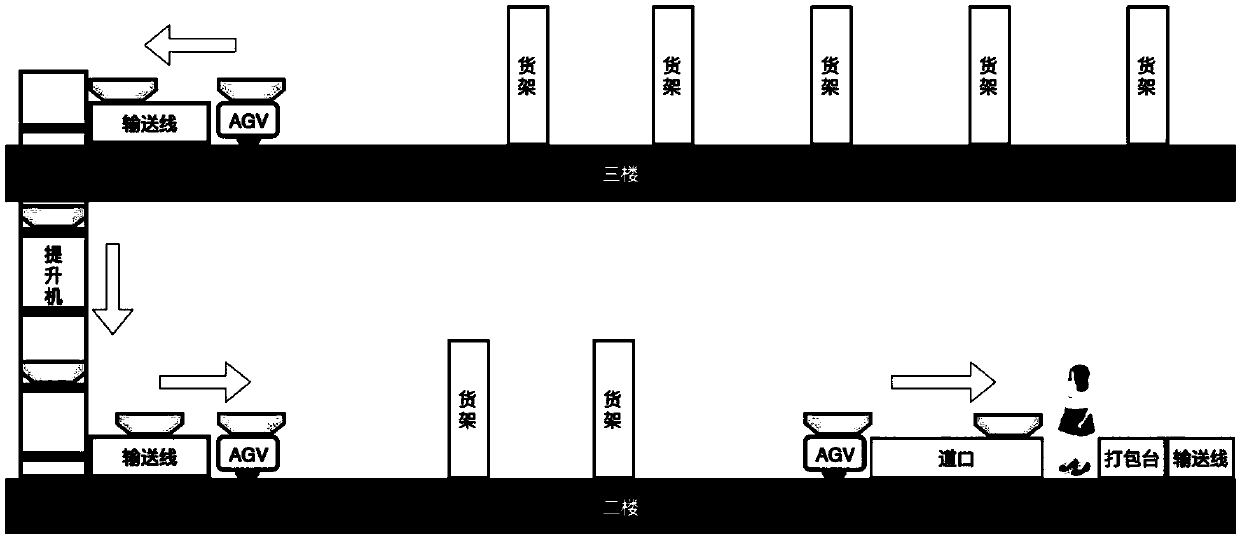

[0064] In the first embodiment, a warehouse operation system is firstly provided, see figure 2 , the warehouse includes a picking area and a packing area, and the picking area includes a plurality of shelves for storing goods;

[0065] Specifically, the system includes: a first server 201, and multiple transport vehicles 202; wherein,

[0066] The first server 201 is configured to generate multiple picking tasks according to the same batch of orders in the warehouse, and distribute the multiple picking tasks to multiple transport vehicles;

[0067] The transport vehicle 202 is configured to obtain a first driving route corresponding to the picking task and a second driving route for transporting the picking result to a destination location; a driving target according to the first driving route At the shelf, after the target goods are loaded, the target goods are transported according to the second driving route.

[0068] Wherein, the first server 201 may specifically be use...

Embodiment 2

[0100] The second embodiment corresponds to the first embodiment, and provides a warehouse order processing method from the perspective of the first server, see Figure 7 , the method may specifically include:

[0101] S701: Generate a picking task according to the order corresponding to the target warehouse;

[0102] S702: Assign the picking task to a transport vehicle in the target warehouse, where the transport vehicle is used to obtain the first driving path for completing the picking task, and to transport the picking result to the destination The second driving route of the position: driving the target shelf according to the first driving route, and transporting the target goods according to the second driving route after the loading of the target goods is completed.

[0103] During specific implementation, the first server is usually located in the cloud, and it is also possible to control the path of the transport vehicle from the cloud. Specifically, the first serve...

Embodiment 3

[0107] The third embodiment also corresponds to the first embodiment, and provides a warehouse operation control method from the perspective of the second server, see Figure 8 , the method may specifically include:

[0108] S801: Obtain map data in the warehouse in advance, the map data including the location of each shelf in the warehouse and the second corresponding relationship between the shelf and the goods;

[0109] S802: Receive the first correspondence relationship information between the transport vehicle identifier and the picking task information provided by the first server;

[0110] S803: Obtain real-time positioning information of the transport vehicle in the warehouse;

[0111] S804: According to the position of the target shelf where the target goods in the picking task are located, the destination location of the delivery, and the real-time positioning information of the transport vehicle, plan a first trip for the transport vehicle to complete the picking tas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com