A transformer high-voltage incoming line insulation protective sleeve

A technology of insulating protective sleeve and high-voltage incoming line, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor parts, electrical components, etc. Easy to fix, easy to install and disassemble, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

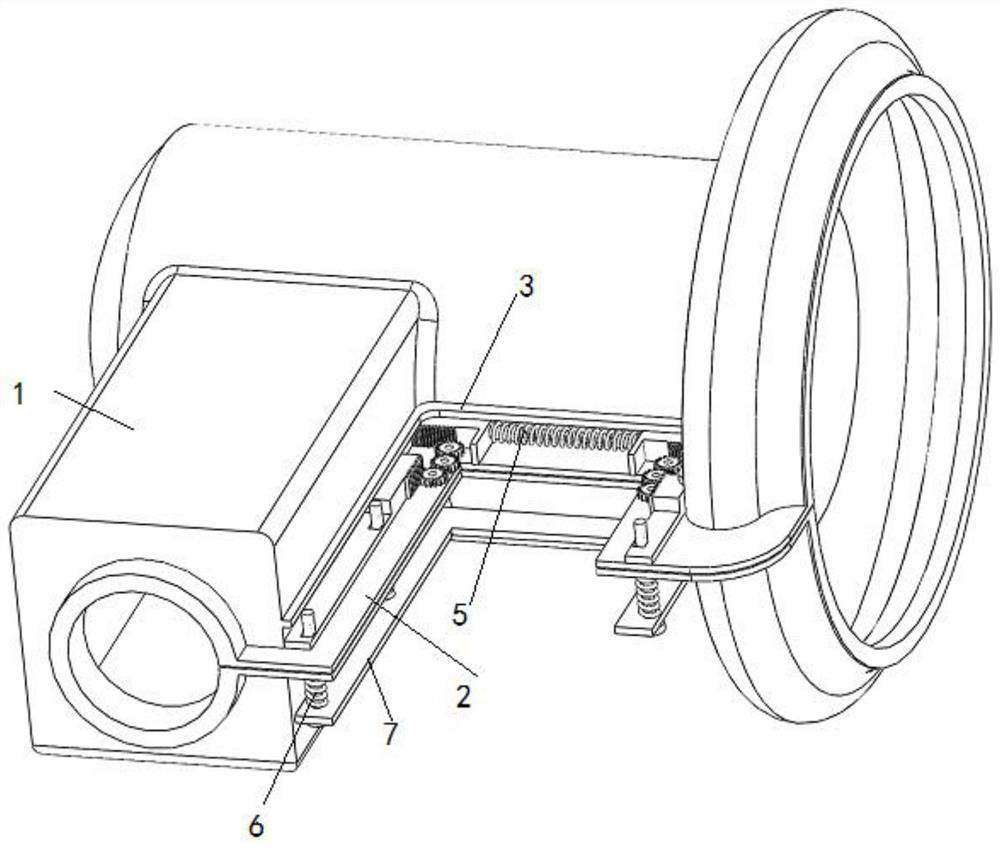

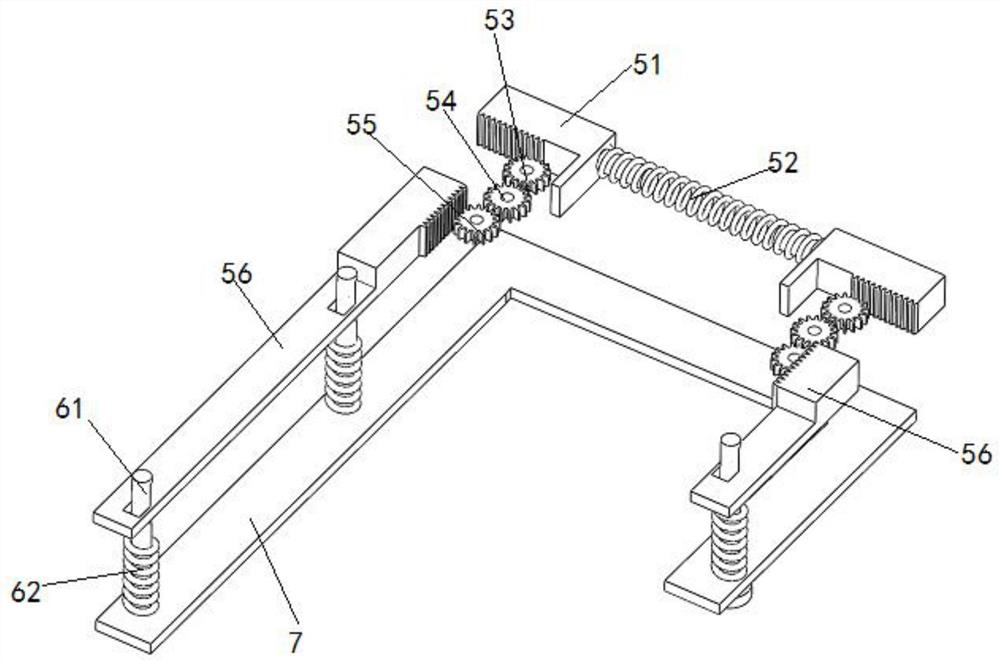

[0029] A transformer high-voltage incoming line insulation protective cover, the protective cover is made of silicone rubber, such as figure 1 As shown, it includes a protective cover body 1 and two oppositely arranged joint parts 2 arranged in the middle part of the side wall of the protective cover body 1. At the same time, the side wall of the protective cover body 1 is provided with a sliding clamping part 3, and the sliding clamping part 3 is connected with the An elastic power mechanism 5 is slidably installed between the joint parts 2, and several locking pieces 6 are installed on the joint part 2 at the same time. When locking, one end of the locking piece 6 passes through the joint part 2 and is locked in the elastic power mechanism 5. The power mechanism 5 limits and fixes the locking piece 6 to realize the fixing of the joint part 2 , and at the same time, several locking pieces 6 are connected and fixed through the push-pull plate 7 .

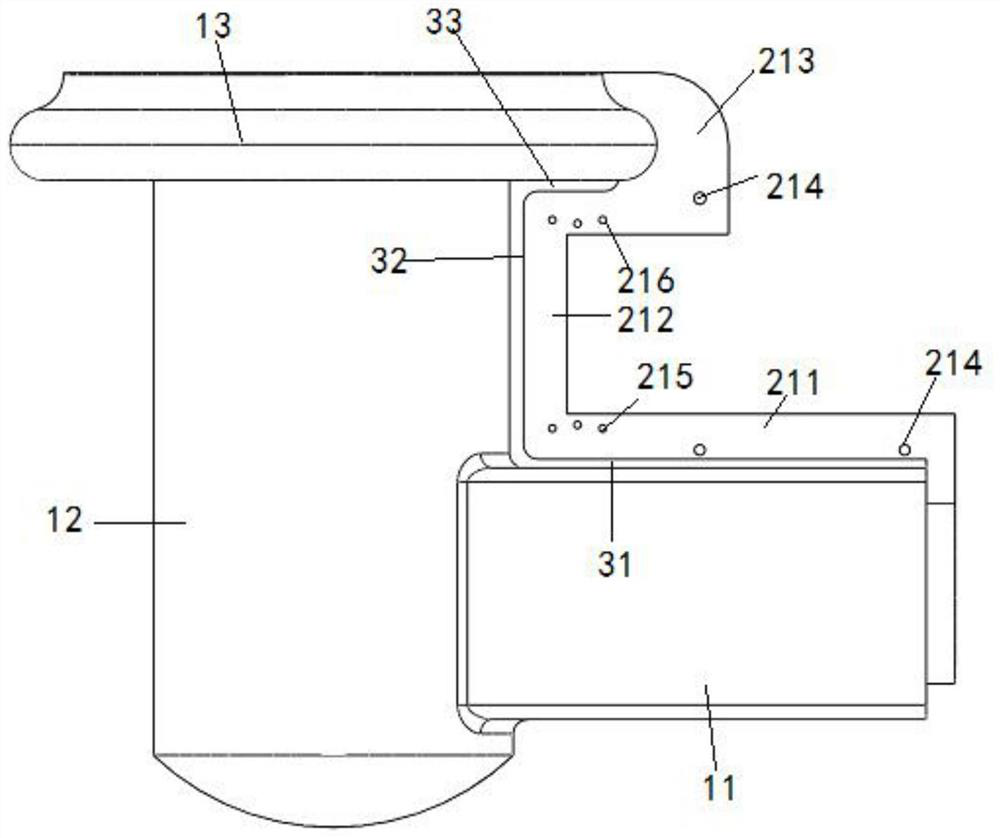

[0030] Such as figure 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com