Quick locking structure for filter element

A locking structure and filter element technology, applied in fixed filter element filters, filtration separation, chemical instruments and methods, etc., can solve the problems of low visibility, potential safety hazards, troublesome disassembly and assembly, etc. The effect of using the experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

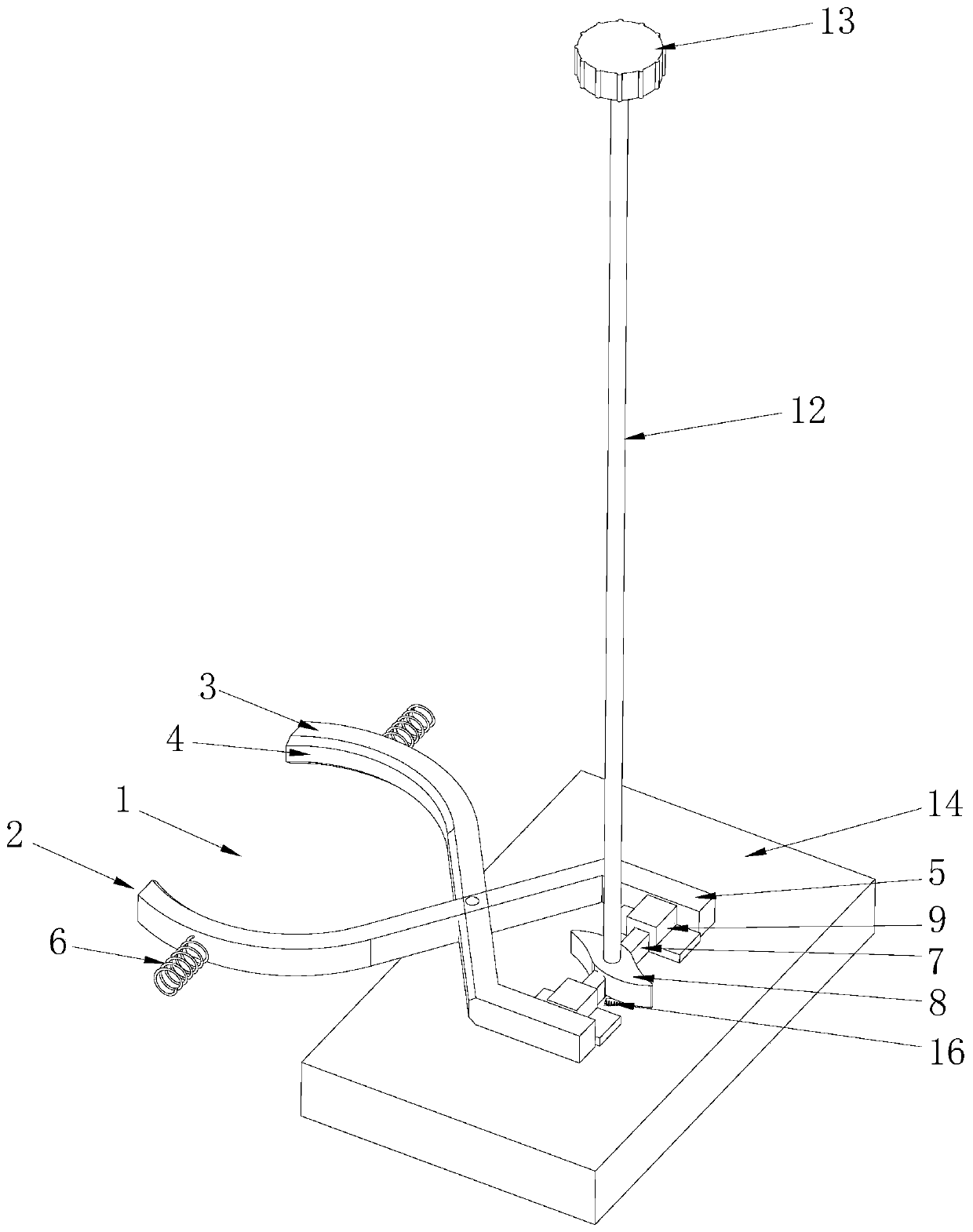

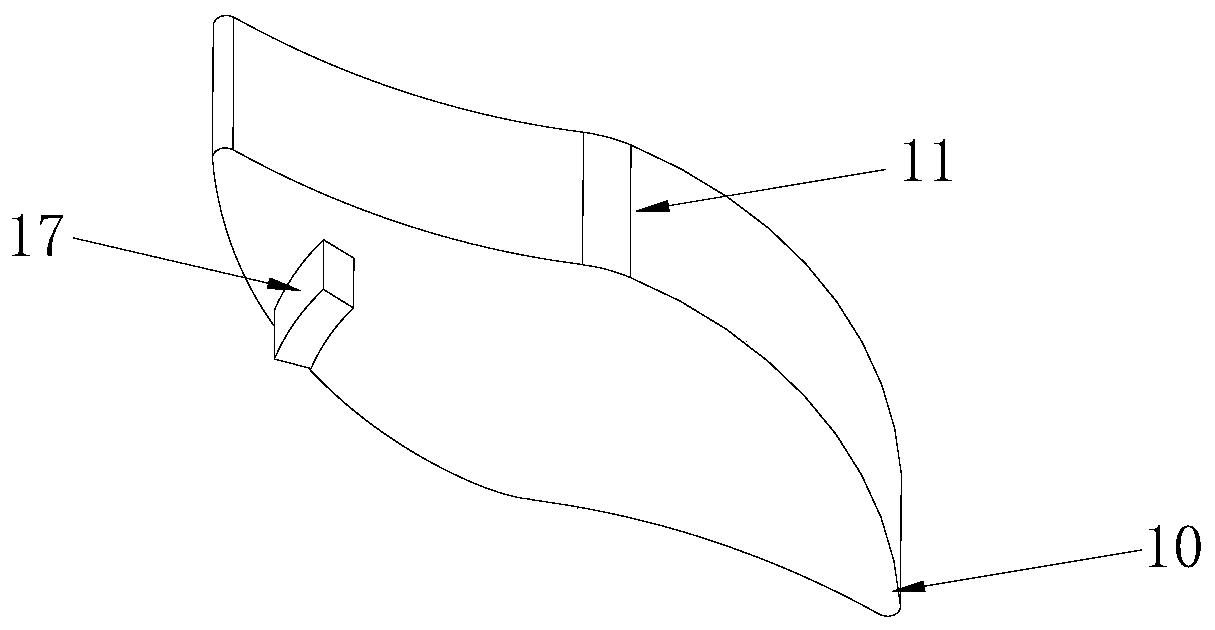

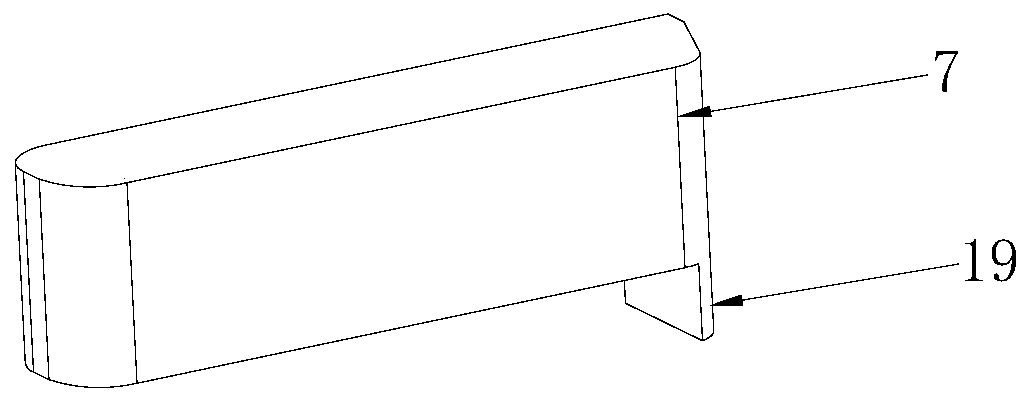

[0037] like Figure 1~4 As shown, the quick locking structure of the filter element in Embodiment 1 includes a locking assembly and a locking space 1 , and the filter element can be installed and locked in the locking space 1 . The locking assembly includes a clamping part, an elastic part and a toggle part, wherein,

[0038] The clamping part includes two locking strips 2, which are arranged symmetrically with respect to the locking space 1 and which are mutually rotatably connected, and the mutual rotation of the locking strips 2 is parallel to The axial direction of the filter element; one end of the two locking strips 2 is provided with a locking end 3 located in the circumferential direction of the locking space 1, the locking end 3 can move relative to the locking space 1 and the two locking ends 3 are symmetrically arranged relative to the locking space 1, The locking end 3 is provided with an extrusion surface 4 that can contact and squeeze the circumferential side of...

Embodiment 2

[0048] The difference between this embodiment 2 and embodiment 1 is that in this embodiment 2, if Figure 5 As shown, the quick locking structure for the filter element also includes an ejection assembly, which is connected with the filter element and generates a force for the filter element to break away from the locking assembly. Specifically, the ejection assembly includes a contact part 20 and an ejection part 21, wherein,

[0049] The contact part 20 can move axially along the filter core relative to the locking space 1; in this embodiment 2, the contact part 20 is a sleeve part, and guide holes arranged along the filter core axial direction are arranged in the sleeve part, and the sleeve The top of the piece is connected with the filter element;

[0050] The ejection part 21 is a spring, and the ejection part 21 is installed in the guide hole, and when the filter element penetrates into the locking space 1, the contact part 20 presses the ejection part 21, and the eject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com