A kind of wood product UV primer vacuum spraying method and UV primer spray paint wood product

A technology for vacuum spraying and wood products, which is applied in coatings, devices for coating liquid on the surface, and surface pretreatment. It can solve the problems of cumbersome treatment process, inability to meet the spraying process, and long time consumption, and achieve simple preparation process. The effect of short time and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

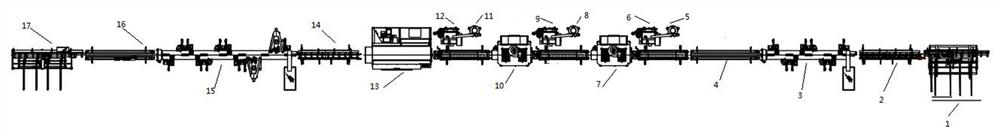

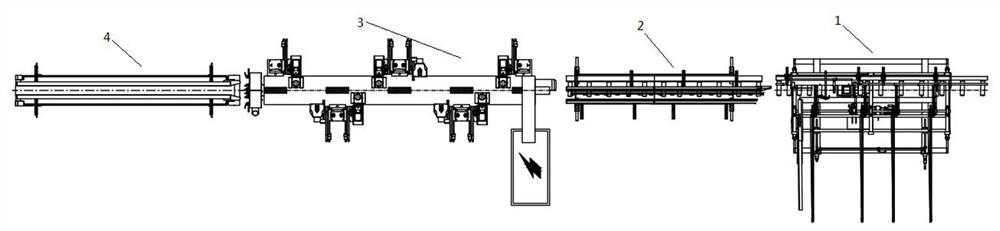

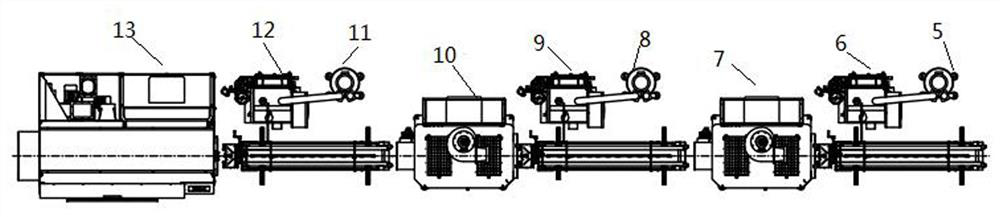

Image

Examples

Embodiment 1

[0024] The wooden line to be treated is polished with a sander and 320# sandpaper to obtain a polished wood product, and the polished wood product is blown with a dust blower, and the dust suction port is vacuumed to obtain a pre-finished product. Deal with wood moldings.

[0025] The proportion of raw materials used is: 14% polyurethane acrylate, 30% epoxy acrylate, 4% 1-hydroxycyclohexyl phenyl ketone, 1% vinyl acetate emulsion, 2-acrylic acid-(1-methyl-1, 2-ethylene) bis (β-methyl chloride ethyl) fat) 67%, 2-methyl-2-acrylic acid (2-hydroxyethyl) fat 32%, talcum powder 1%, the rest is UV monomer Polyester compounded UV primer, and configured into polyester compounded UV primer solution with viscosities of 30 seconds, 45 seconds and 35 seconds in Iwata No. 2 cup.

[0026] The pretreated solid wood door is first vacuum sprayed with a polyester compound UV primer with a viscosity of Iwata No. 2 cup for 30 seconds, and the spraying amount is 35g / ㎡, and UV light curing is carri...

Embodiment 2

[0028] The wooden door cover to be treated is polished by a sander with a mesh number of 320# sandpaper to obtain a polished wood product, and the polished wood product is blown with a dust blower, and the dust suction port is vacuumed to obtain Pre-treated wooden door casings.

[0029] The proportion of raw materials used is: 12% polyurethane acrylate, 25% epoxy acrylate, 3% 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 0.5% acrylic emulsion, 2-acrylic acid- (1-methyl-1,2-ethylene)bis(β-methylchloroethyl) ester) 67%, 2-methyl-2-acrylic acid (2-hydroxyethyl) ester 32%, talcum powder 1 %, the rest is the polyester compound UV primer of UV monomer, and is configured into a polyester compound UV primer solution with a viscosity of 25 seconds, 35 seconds and 30 seconds for Iwata No. 2 cup.

[0030]The pretreated wooden door cover is vacuum sprayed for the first time with a polyester compound UV primer with a viscosity of Iwata No. 2 cup for 25 seconds, and the spraying amount i...

Embodiment 3

[0032] The solid wood door frame to be treated is polished by a sander with a mesh number of 400# sandpaper to obtain a polished wood product, and the polished wood product is blown with a dust blower, and the dust suction port is vacuumed to obtain Pre-treat wooden door frames.

[0033] The ratio of the raw materials used is: 13% polyurethane acrylate, 28% epoxy acrylate, 4.5% α-hydroxyalkyl phenone, 0.8% acrylic emulsion, 2-acrylic acid-(1-methyl-1,2-methacrylate Ethyl) bis(β-methylchloroethyl) fat) 67%, 2-methyl-2-acrylic acid (2-hydroxyethyl) fat 32%, talcum powder 1%, and the rest are polyesters of UV monomers Compound the UV primer, and configure it into a polyester compounded UV primer solution with a viscosity of 35 seconds, 40 seconds and 45 seconds for Iwata's No. 2 cup.

[0034] The pre-treated solid wood door is vacuum-sprayed for the first time with a polyester compound UV primer with a viscosity of Iwata No. 2 cup for 35 seconds, and the spraying amount is 28g / ㎡...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com