Passenger train framework side frame welding positioning tooling

A technology for welding positioning tooling and railway passenger cars, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., and can solve the problem of lack of positioning reference objects in the main load-bearing frame structure, high labor intensity for operators, and inconvenient storage management and other problems, to achieve the effect of reducing calibration surveying and mapping work, improving overall work efficiency, and simplifying workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

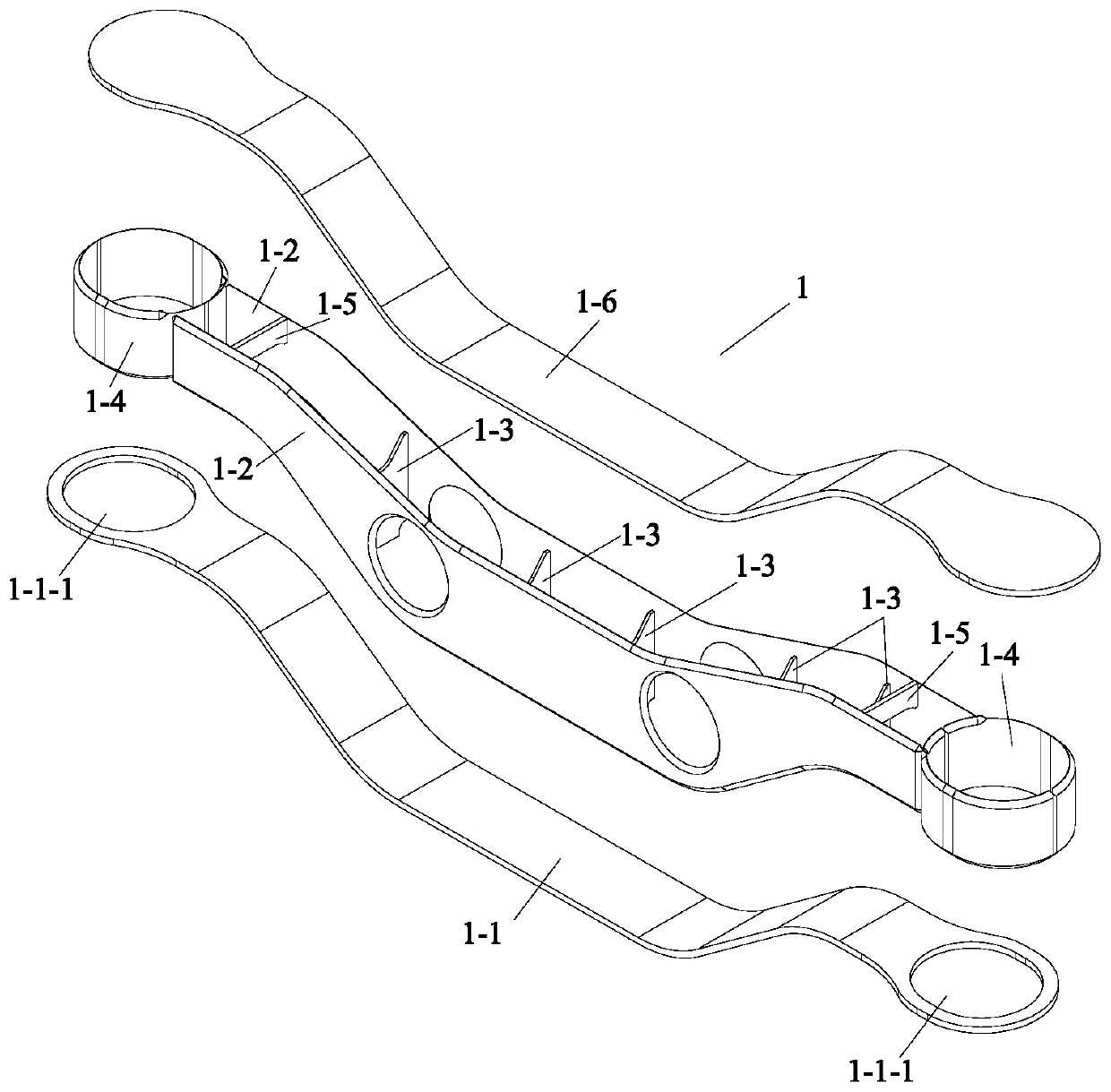

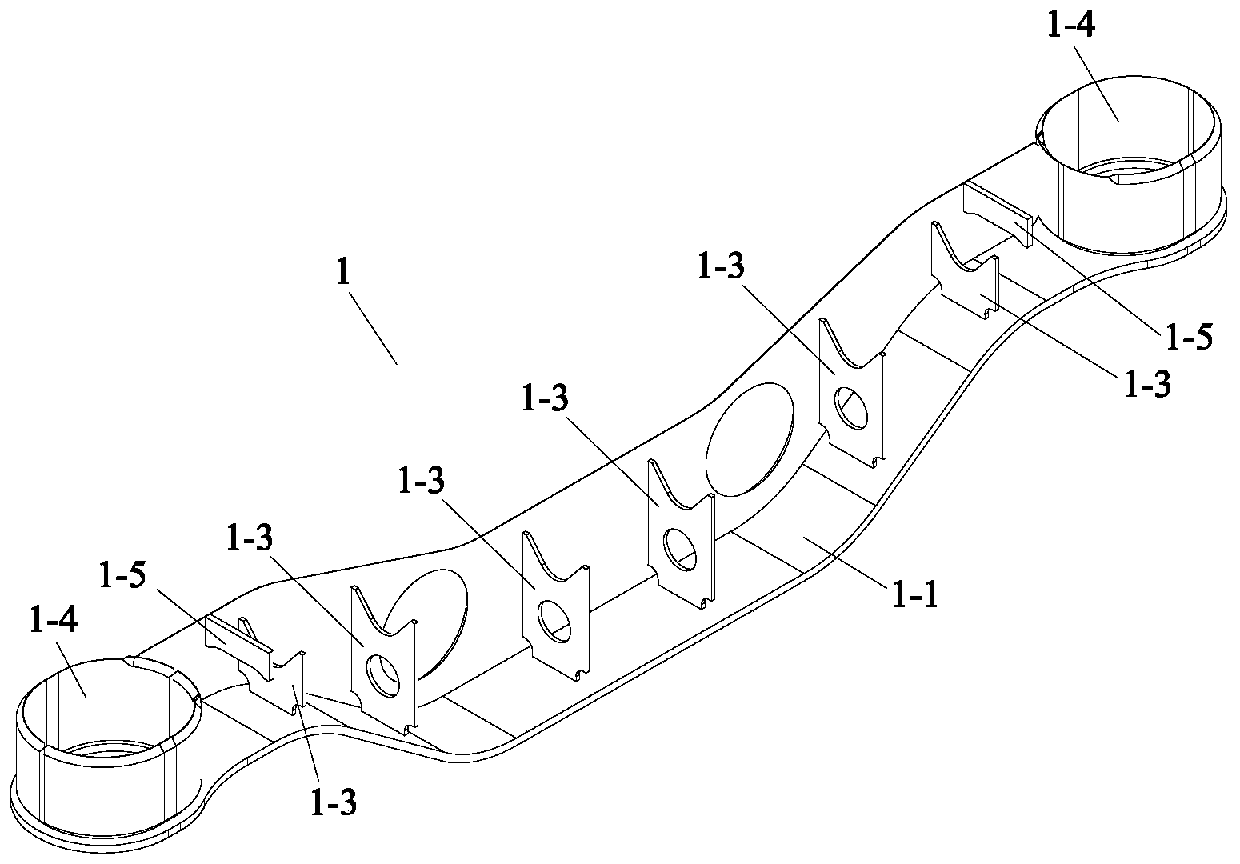

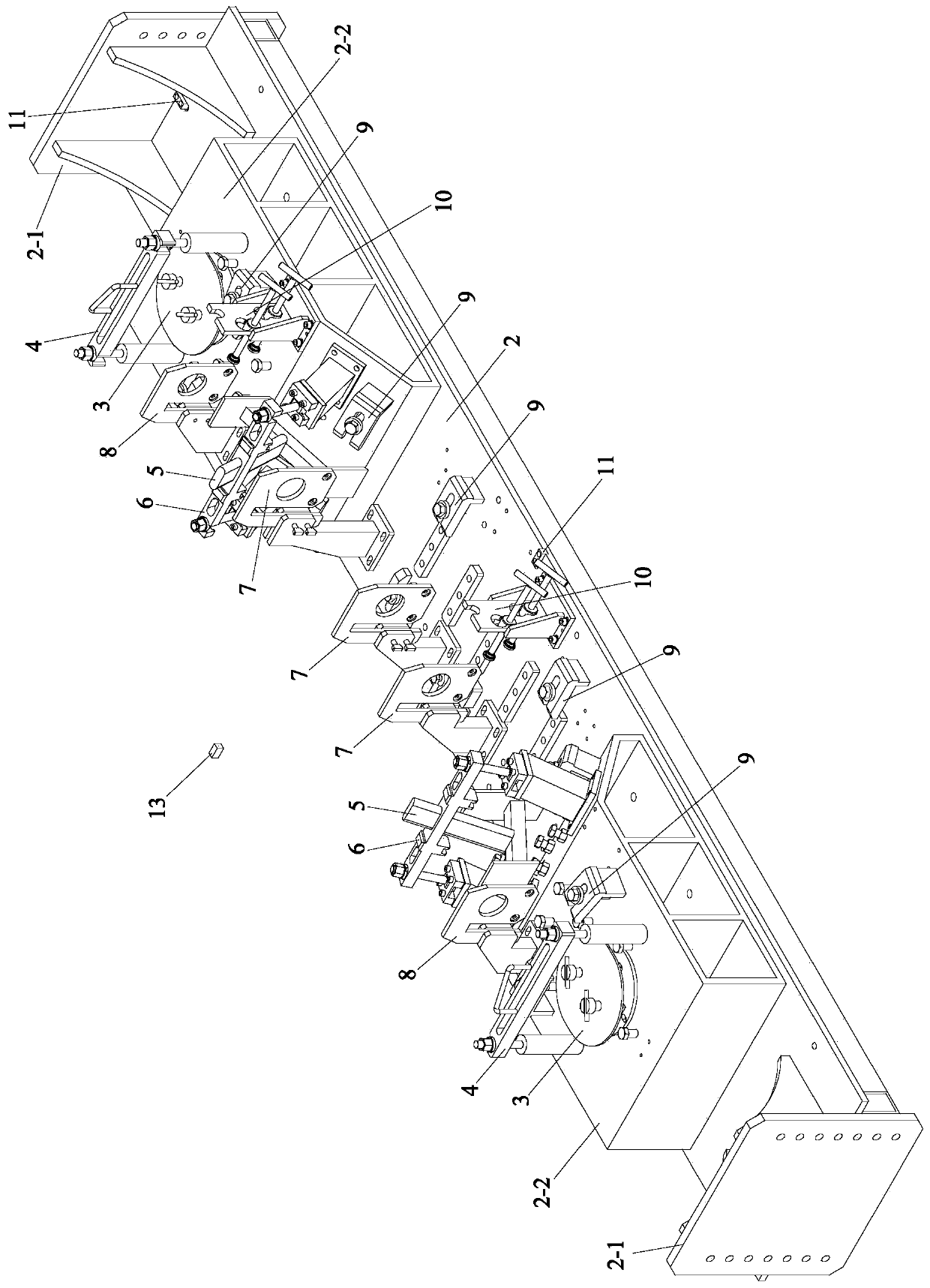

[0054] like Figure 3 to Figure 13 As shown, the railway passenger car frame side beam welding positioning tool of the present invention includes a base 2, two cap barrel centering mechanisms 3, two cap barrel pressing mechanisms 4, two inclined-plane vertical rib positioning mechanisms 5, two vertical plate pressure Tightening mechanism 6, three plane vertical rib positioning mechanisms 7, two horizontal rib positioning mechanisms 8, multiple lower cover pressing mechanisms 9, two vertical plate side tightening mechanisms 10, four reference positioning blocks 11, and a lower cover Plate positioning block press clamp 12 and a lower cover plate positioning blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com