Tire gravel scraping equipment

A stone and tire technology, applied in the field of tire stone particle scraping equipment, can solve the problems of difficult scraping, low work efficiency, stuck stone particles, etc., and achieves the effect of reducing vibration, reducing work difficulty and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

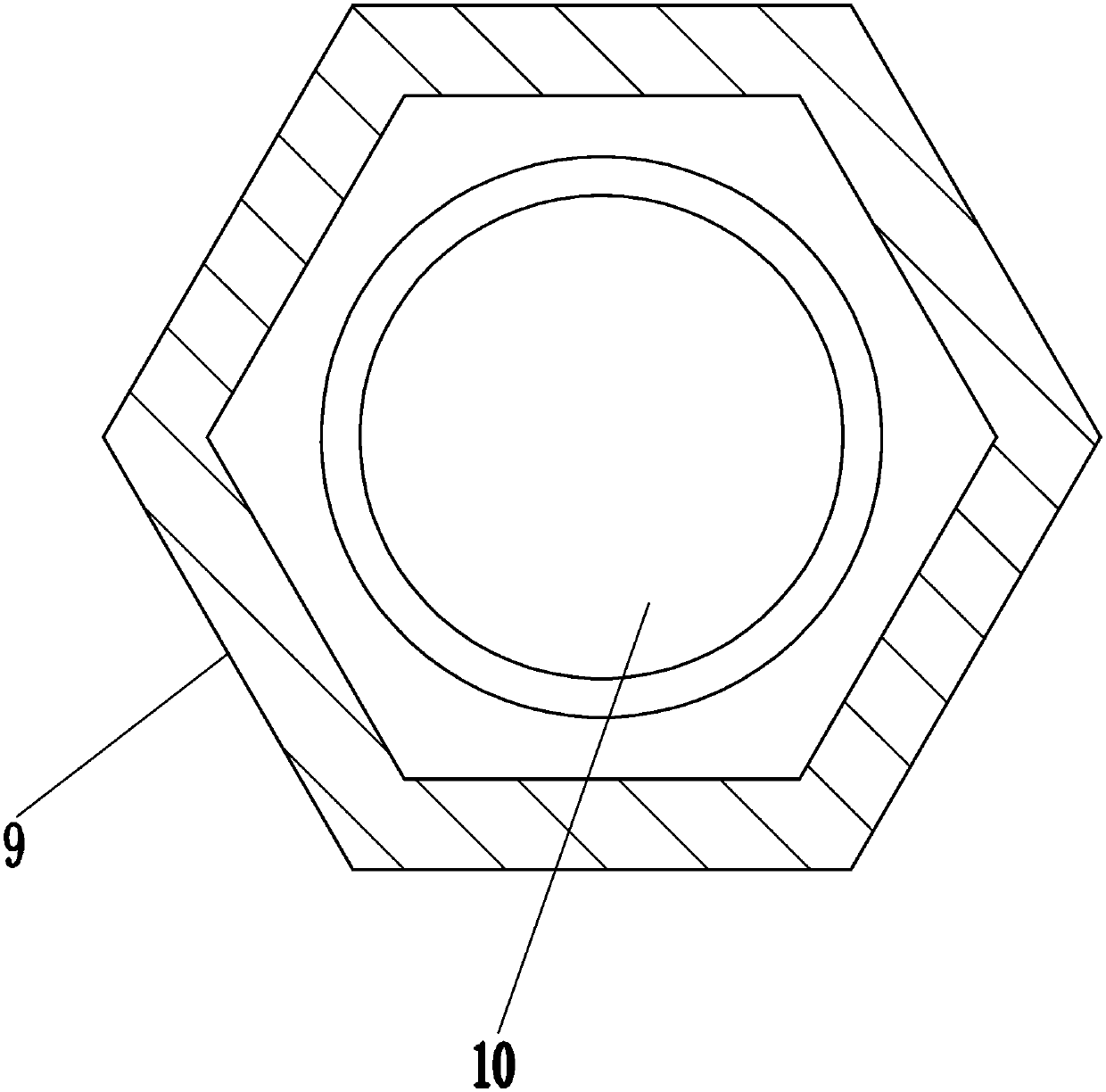

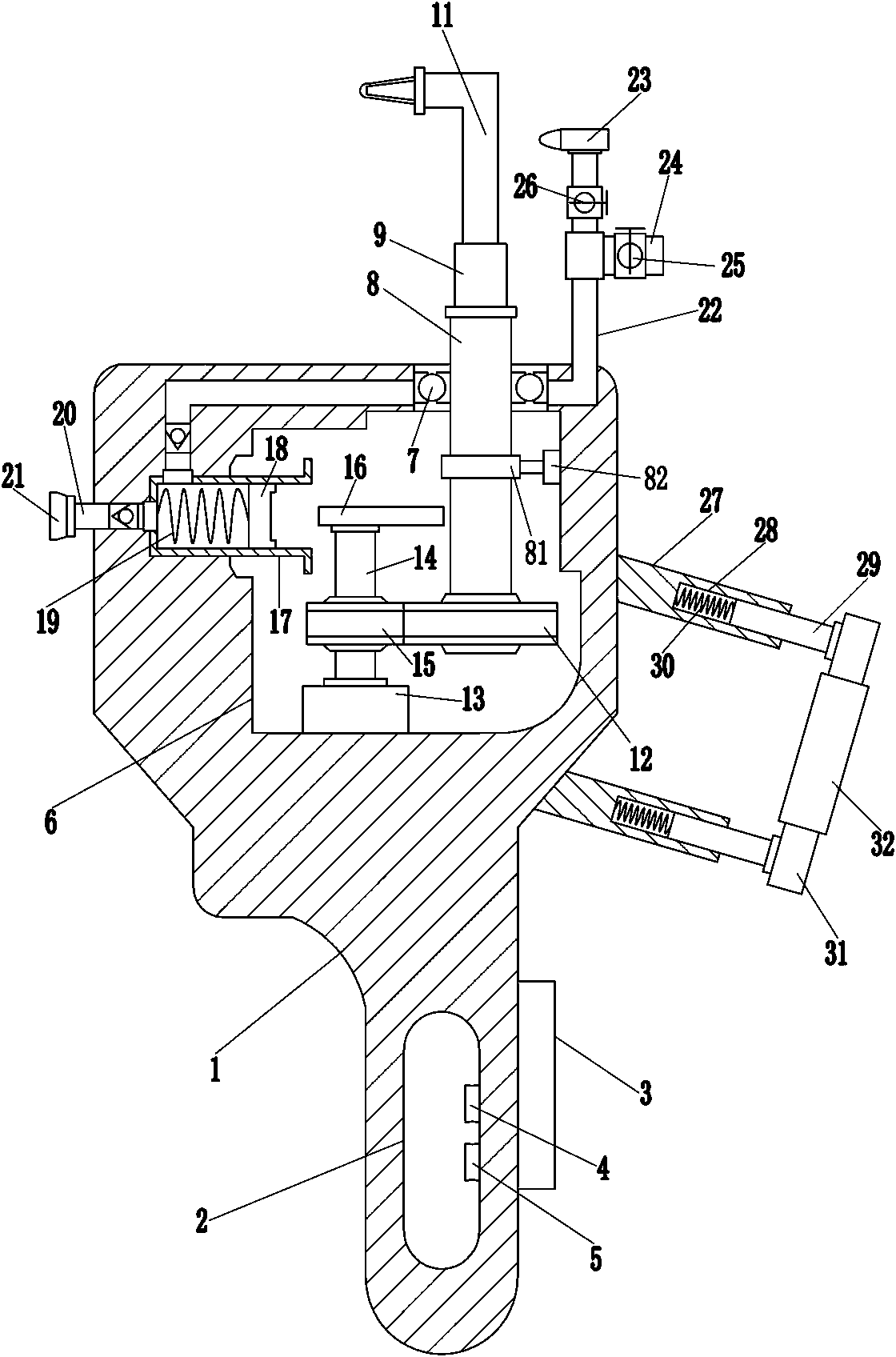

[0018] A kind of scraping equipment for tire stone particles, please refer to figure 1 As shown, it includes a mounting block 1 and a motor 13. A first cavity 6 is opened on the top of the mounting block 1. A motor 13 is installed at the bottom of the first cavity 6. It also includes a scraper rod 11, a connecting device, and a first rotating shaft. 8. The first gear 12, the second gear 15 and the second shaft 14, the output shaft of the motor 13 is equipped with the second shaft 14, the second shaft 14 is equipped with the second gear 15, the first shaft 8 is installed on the installation block 1 and penetrate into the first cavity 6, the first shaft 8 is equipped with a first gear 12, the second gear 15 meshes with the first gear 12, and the scraper rod 11 is connected with the first shaft 8 through a connecting device; the connection The device is a hexagonal sleeve 9, the top of the first rotating shaft 8 is fixedly connected to the hexagonal sleeve 9, and the hexagonal sl...

Embodiment 2

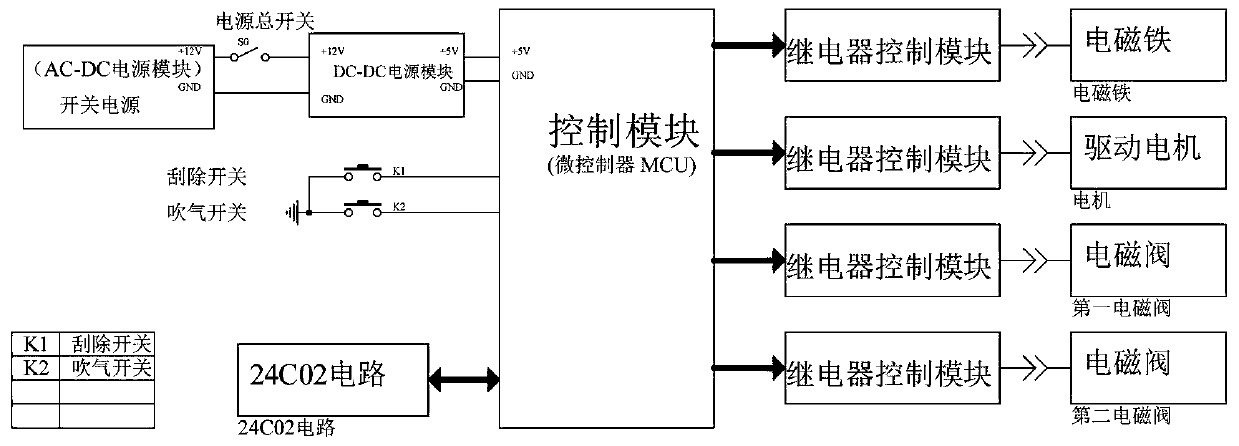

[0020] A kind of scraping equipment for tire stone particles, please refer to figure 1 , figure 2 , Figure 4 and Figure 5 As shown, it includes a mounting block 1, a control box 3, a scraper switch 4, a blower switch 5, a bearing seat 7, a first rotating shaft 8, a receiving coil 81, an electrode 82, a hexagonal sleeve 9, an electromagnet 10, a scraper Remove rod 11, first gear 12, motor 13, second rotating shaft 14, second gear 15, cam 16, cylinder 17, piston 18, first compression spring 19, intake pipe 20, filter sleeve 21, exhaust pipe 22 , nozzle 23, two branch pipes 24, the first solenoid valve 25 and the second solenoid valve 26, the lower part of the installation block 1 has a groove 2, the lower part of the right side of the installation block 1 is equipped with a control box 3, and the installation block 1 is connected by bolts It is connected with the control box 3. The control box 3 includes a switching power supply, a power supply module and a control module....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com