A kind of hydraulic system cavitation removal device and method with hydraulic lock

A technology of hydraulic system and removal device, applied in the direction of fluid pressure actuating device, fluid pressure actuating system components, mechanical equipment, etc., can solve the problems of deterioration of fluid flow characteristics, no cavitation removal, hydraulic device noise, etc., Achieve the effect of eliminating air pockets, carrying less tools and investing less personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In an embodiment of the present invention, a hydraulic system cavitation elimination device with a hydraulic lock is applied to a blast furnace hot blast stove hydraulic system. The development of large-scale blast furnace is a manifestation of the improvement of the technical level of the current ironmaking equipment, and it is also an inevitable trend. The enlargement of the blast furnace puts forward new requirements for the equipment in front of the furnace, and the hot blast furnace equipment must also be developed in the direction of large-scale, intelligent and environmental protection in order to meet the production requirements of large blast furnaces. Each blast furnace hot blast stove has about 63 hot blast valves controlled by hydraulic cylinders, and the opening and switching status of these hot blast valves are controlled by the hydraulic system.

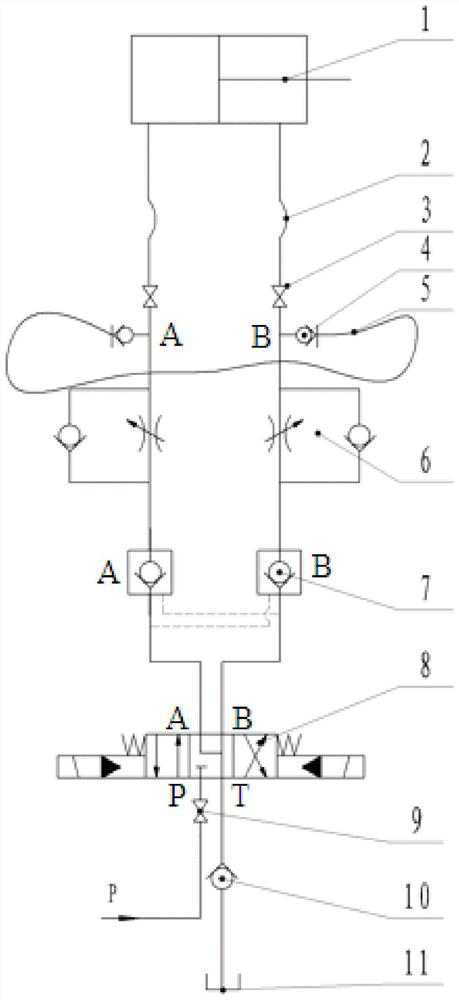

[0032] see figure 1 The hydraulic system cavitation elimination device includes a hydraulic cylinder 1, a va...

Embodiment 2

[0038] Based on the same inventive concept, an embodiment of the present invention provides a method for eliminating cavitation in a hydraulic system with a hydraulic lock, and the method is applied to a hydraulic system of a blast furnace hot blast stove.

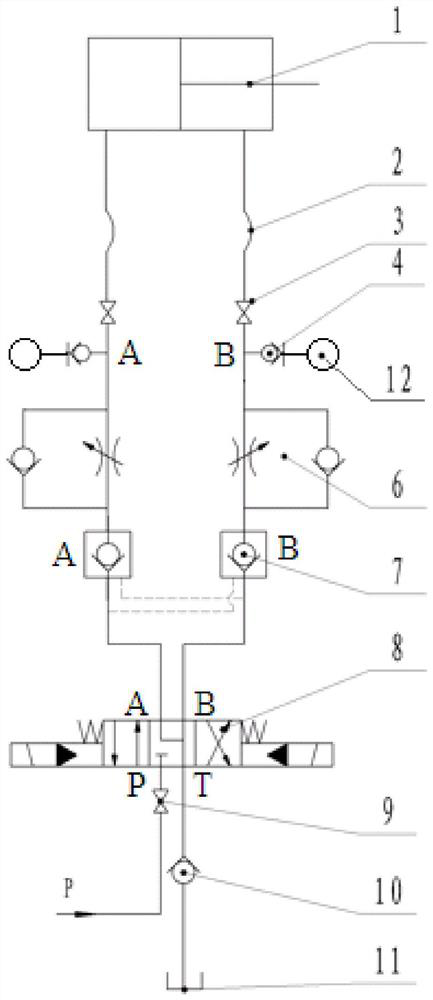

[0039] see figure 2 , the hydraulic system of the blast furnace hot blast stove includes a hydraulic cylinder 1, a valve 3, a one-way throttle valve 6, a hydraulic lock 7, a reversing valve 8, a main control valve 9, a one-way valve 10 and an oil tank 11. The above-mentioned hydraulic cylinder 1, valve 3. One-way throttle valve 6, hydraulic lock 7, reversing valve 8 and oil tank 11 are sequentially connected through hydraulic oil pipe 2 (high-pressure hose, inner diameter is 20mm), forming a large-flow working hydraulic circuit. The system oil pressure of the hydraulic system P is 12MPa, hydraulic cylinder 1 adopts single-rod double-acting hydraulic cylinder.

[0040] In the hydraulic system of the blast furnace hot blas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com