Transformer locknut assembly

A technology of anti-loosening nuts and transformers, which is applied to parts of transformers/inductors, nuts, threaded fasteners, etc. It can solve problems such as poor sealing and fastening, loosening of transformer valves, oil leakage, etc., and achieve enhanced sealing and tightness. Solid effect, prevent loosening, and prevent oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

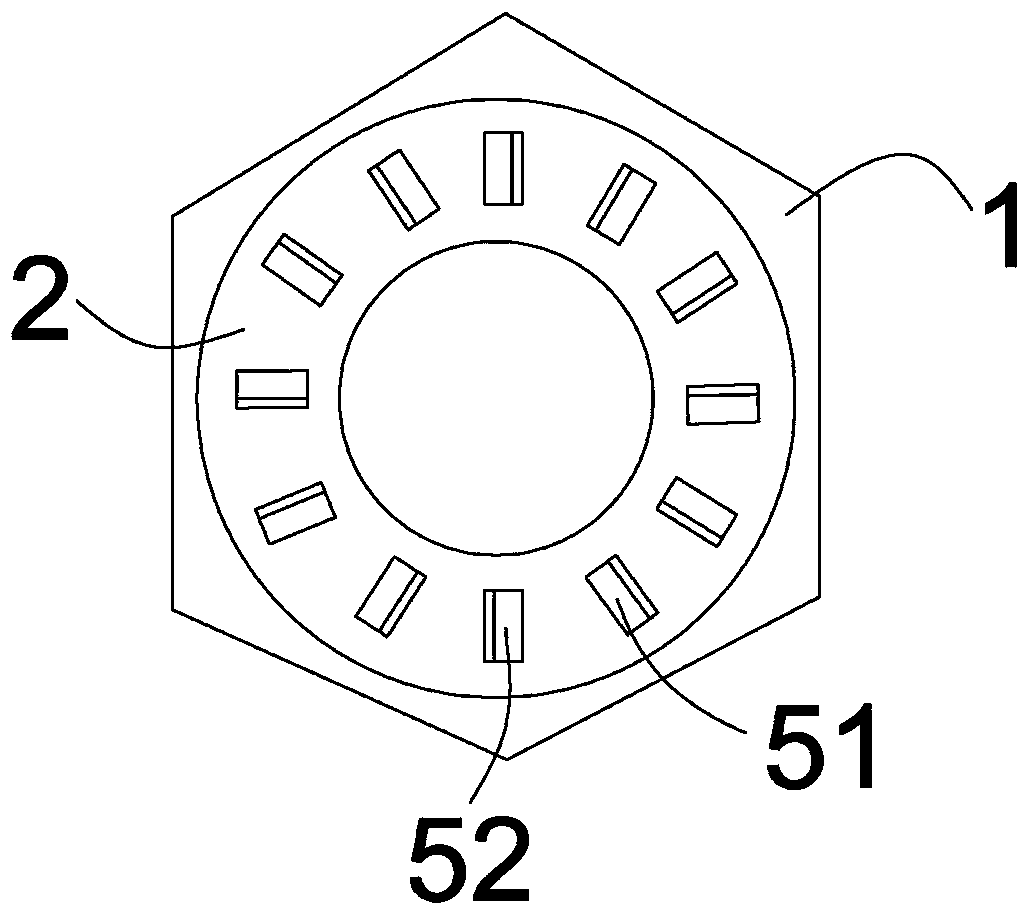

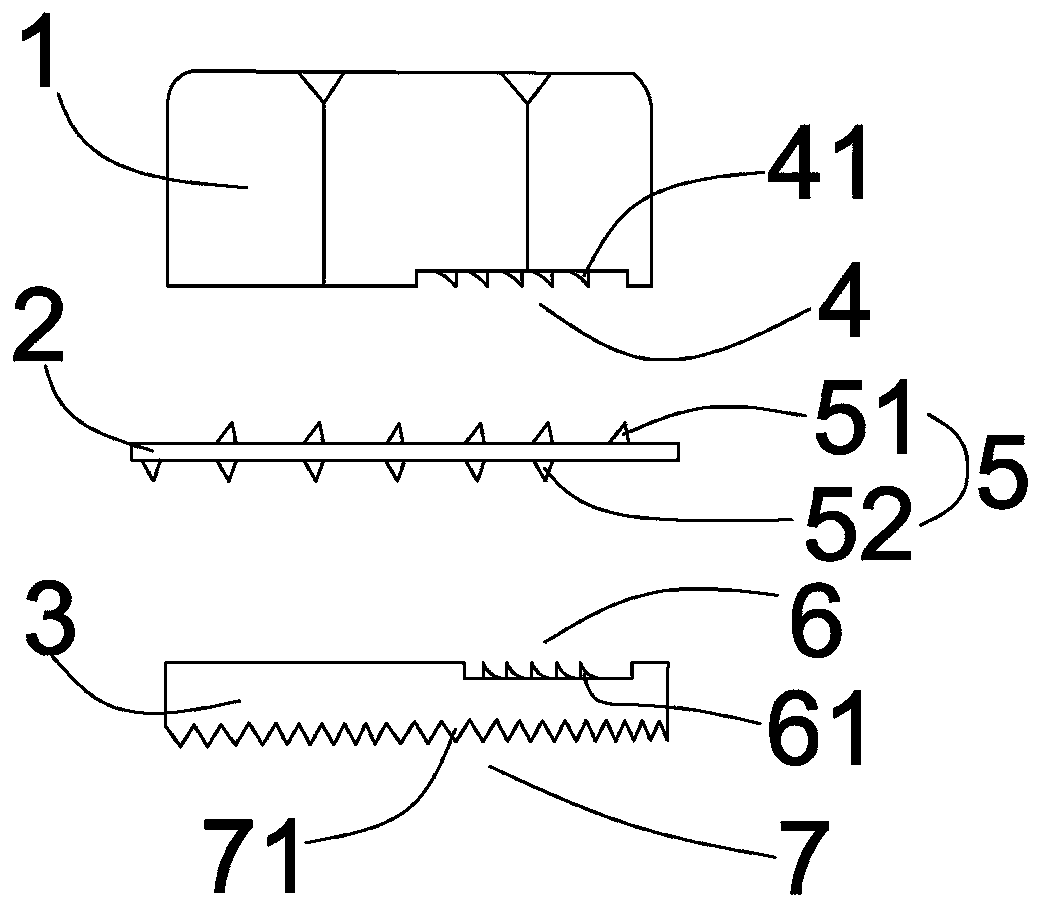

[0026] The present invention is a transformer locknut assembly, such as figure 1 , 2 , 3 and 4, including a nut 1, an anti-return self-locking elastic lock ring 2 and a lock washer 3, and the anti-retreat self-lock elastic lock ring 2 is arranged between the nut 1 and the lock washer 2; the nut The lower surface is provided with a first thread 4, the first thread is five first raised strips 41 distributed on the lower surface of the nut, the length of the first raised strip is the circumference of the radius of the nut where the first raised strip is located Half of the length, half of the circumference of the lower surface of the nut does not have the first boss strip, providing a space for active fastening, so that it cannot be further tightened when it is loose and not locked. The shape of the cross-section of the first raised bar is triangular, such as figure 2 As shown, it is further a right-angled triangle, one of the right-angled sides is fixedly connected to the low...

Embodiment 2

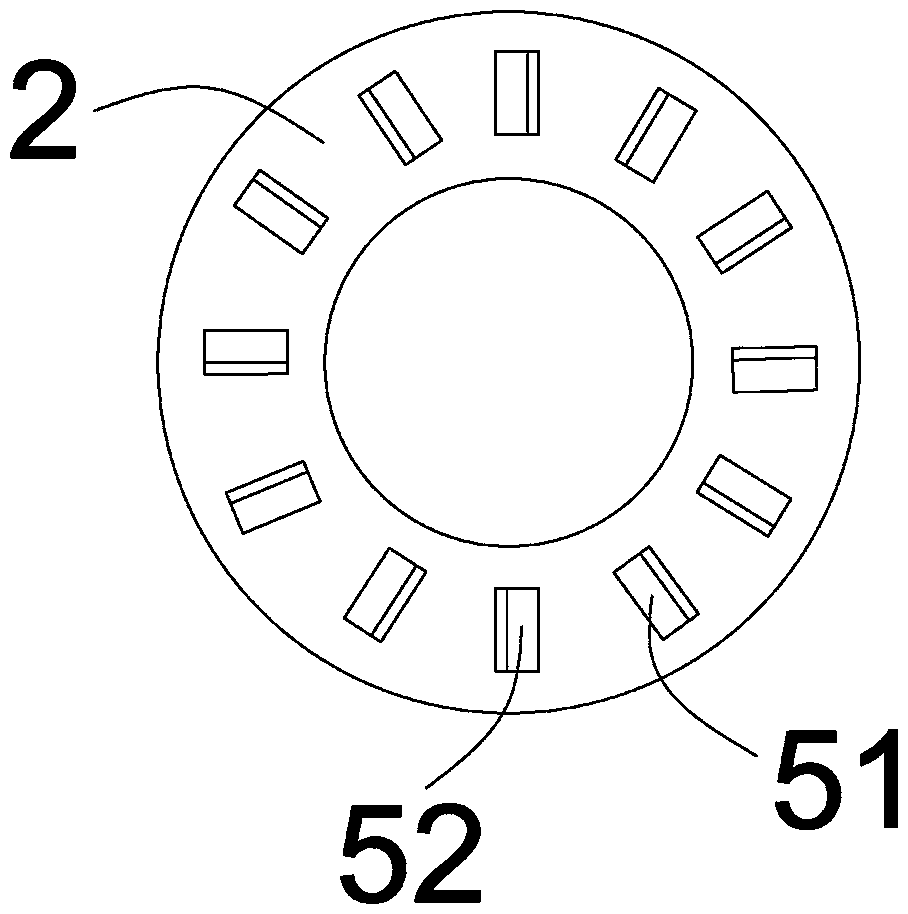

[0030] The difference from Example 1 is that the anti-back self-locking elastic lock ring, such as Figure 5 As shown, an upward-turning rectangular upper flap 510 is arranged on the peripheral edge of the anti-back self-locking elastic lock ring, and a downward-turning rectangular lower flap 520 is arranged on both sides of the upper flap 510, which are arranged alternately in turn to surround the entire peripheral edge; Folding has a certain set angle, which is 45 degrees here, and all the flaps form an inclined plane. When the lock is reversed, the first straight tooth will be against the back of the slope, so that it cannot be loosened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com