Fly Ash Plasma Treatment Plant

A processing device, plasma technology, applied in the direction of combustion type, lighting and heating equipment, incinerator, etc., can solve the problems of high processing cost, high selectivity of furnace material, and unobvious economic benefits, so as to improve the degree of harmlessness , Improve the thoroughness of melting and the effect of improving the degree of harmless treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

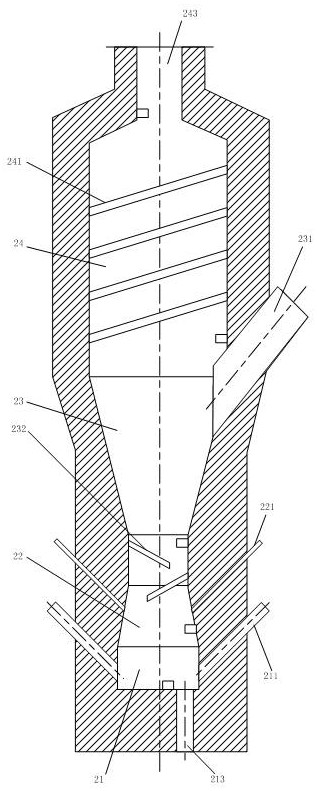

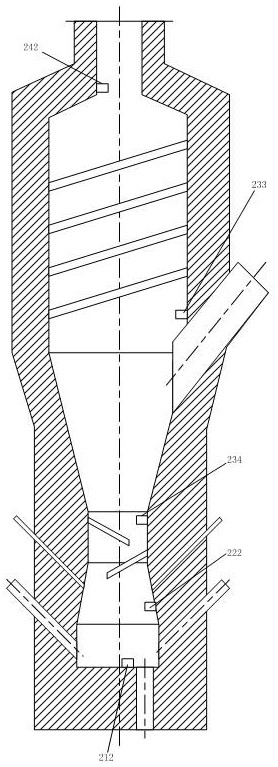

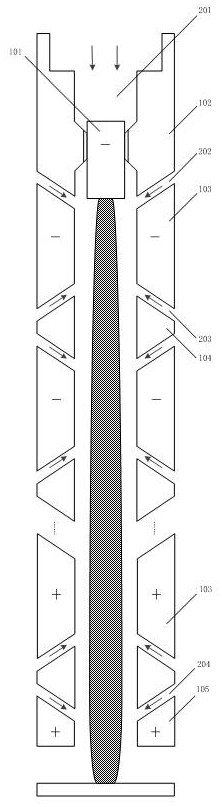

[0030]This embodiment provides a fly ash plasma treatment device, such asfigure 1 As shown, from the lowermost, the molten combustion chamber 21, the hydrate chamber 22, the feed chamber 23, and the extra gas increase room 24;

[0031]The plasma torch generator 211 is attached to the side wall of the molten combustion chamber 21, and the bottom portion of the molten combustion chamber 21 is provided with a slag portion 213; preferably, the number of plasma torch generators 211 is more than two, all cloth in melting On the sidewall of the combustion chamber 21; preferably, the bottom plane of the molten combustion chamber 21 is inclined to the slaglet 213 side, to facilitate the flow of the vitreous waste from the slag portion 213;

[0032]The sidewalls of the hydrate chamber 22 are tilted and attached to the gas intake passage 221, and the gas intake passage 221 is connected to the gas intake passage 221, which is used to function according to the temperature of the temperature in the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com